Antibacterial non-stick pan handle and preparation method thereof

A pot handle and nano-silver technology, applied in the field of functional plastics, can solve the problems of no antibacterial, corrosion, etc., and achieve the effects of high-efficiency antibacterial effect, cost reduction, and balanced physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

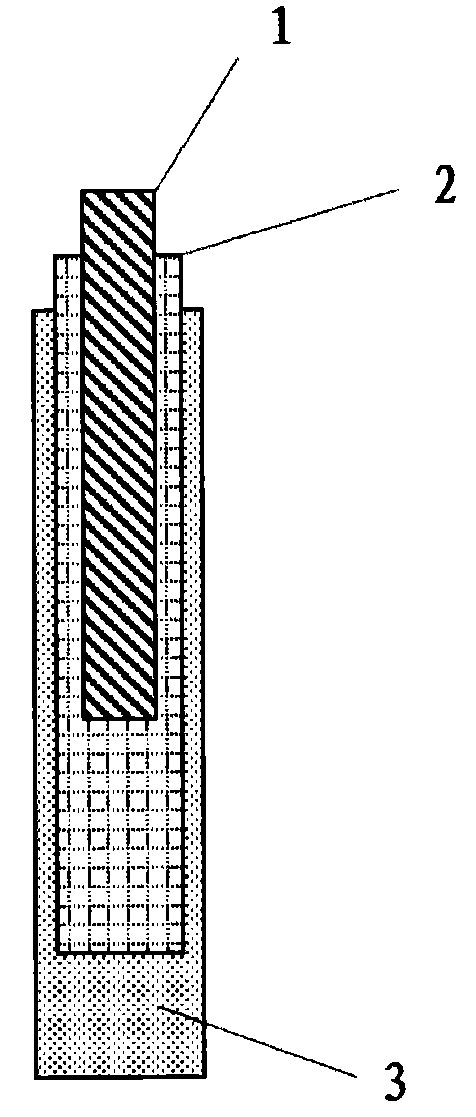

[0029] Correspondingly, the present invention also provides a method for preparing the above-mentioned antibacterial non-stick pan handle, which includes the following steps: pour 20-25 parts by weight of polytetrafluoroethylene into the first mold, heat to 330-380°C, and make the non-stick handle The body of the pot handle is inserted into the first mold, and after heat preservation, it is lowered to 280-320°C, and after heat preservation for 20-60 minutes, the temperature is lowered to form, and the crude non-stick pot handle is obtained; 20-25 parts by weight of polyphenylene sulfide, 20-25 parts by weight Pour parts by weight of polytetrafluoroethylene, 0.5-1 parts by weight of silicone cross-linking agent and 1-5 parts by weight of nano-silver into the second mold, heat up to 330-380 ° C, stir and melt, and then put the non-stick pan handle The crude product is inserted into the second mold, cooled to 280-320° C. for heat preservation, and the antibacterial non-stick pan h...

Embodiment 1

[0042] Pour 20 parts by weight of polytetrafluoroethylene into the mold, heat it to 350°C, then put the handle of the non-stick pan into the mold, keep it warm for 10 minutes, then lower it to 300°C and keep it warm for 30 minutes, then gradually lower it to room temperature to form a crude product; Then pour 20 parts by weight of polyphenylene sulfide, 20 parts by weight of polytetrafluoroethylene, 0.5 parts by weight of crosslinking agent, and 1 part by weight of nano-silver into the mold, heat up to 350 ° C, stir and melt evenly, and then put the upper step of non-stick Put the rough product of the pot handle into the mold, cool it down to 300°C and keep it warm for 1 hour, then gradually lower it to room temperature to get a non-stick pot handle with an antibacterial surface, and then polish it smooth to get the product.

[0043] In order to verify the bactericidal and antibacterial efficacy of the present invention, the handle of the non-stick pan prepared above was immers...

Embodiment 2

[0046] Pour 20 parts by weight of polytetrafluoroethylene into the mold, heat it to 350°C, then put the handle of the non-stick pan into the mold, keep it warm for 10 minutes, then lower it to 300°C and keep it warm for 30 minutes, then gradually lower it to room temperature to form a crude product; Then pour 20 parts by weight of polyphenylene sulfide, 20 parts by weight of polytetrafluoroethylene, 0.5 parts by weight of crosslinking agent, and 2 parts by weight of nano-silver into the mold, heat up to 350 ° C, stir and melt evenly, and then put the upper step of non-stick Put the rough product of the pot handle into the mold, cool it down to 300°C and keep it warm for 1 hour, then gradually lower it to room temperature to get a non-stick pot handle with an antibacterial surface, and then polish it smooth to get the product.

[0047] In order to verify the bactericidal and antibacterial efficacy of the present invention, the handle of the non-stick pan prepared above was immer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com