Premixed polyether polyol, polyurethane raw material composition, foam and preparation method and application of foam

A raw material composition and technology of combining polyether, which is applied in the field of polyurethane, can solve the problems of low low-temperature dimensional stability, high refrigerator filling volume, and high thermal conductivity, and achieve good low-temperature dimensional stability, large space, and low thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

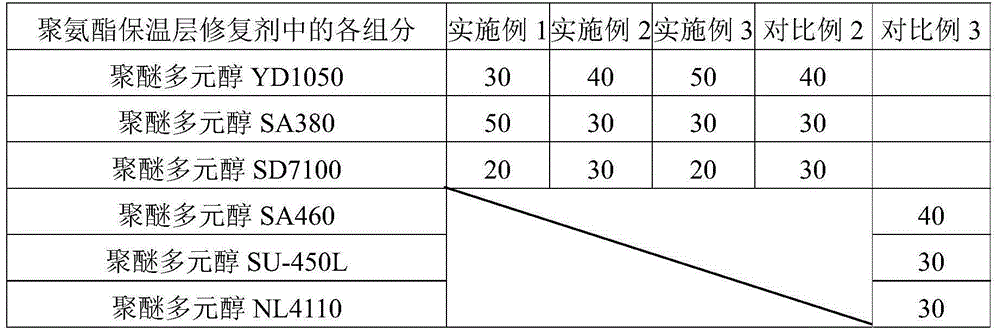

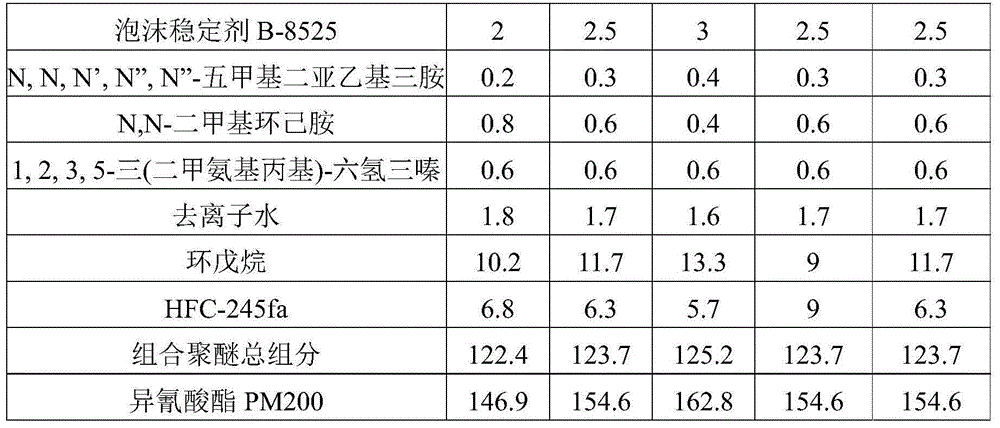

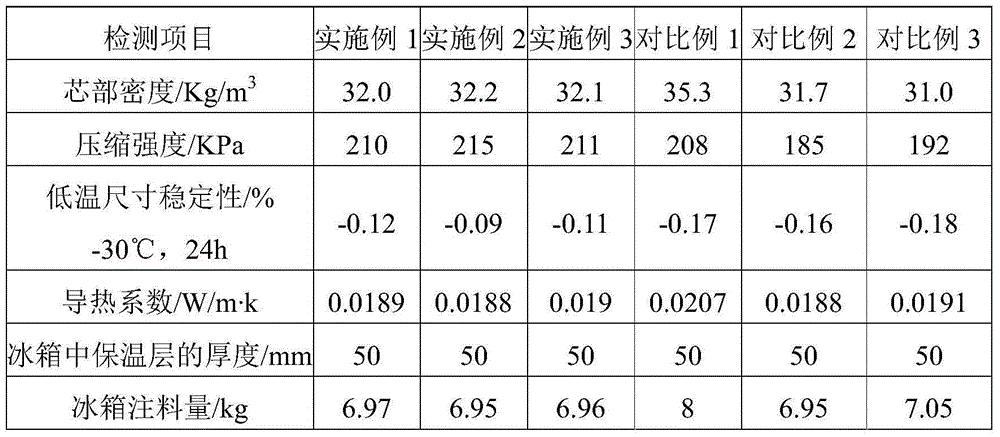

[0039] The parts by weight of each component of the raw material composition of polyether and isocyanate in Examples 1-3 and Comparative Example 2 are specifically shown in Table 1.

[0040] Table 1

[0041]

[0042]

[0043] (1) Preparation of combined polyether

[0044] Mix other components except foaming agent and isocyanate uniformly in a stainless steel mixing tank for 45 minutes, then freeze the mixture to 14°C, add the above foaming agent, and continue mixing for 15 minutes.

[0045] (2) Preparation of polyurethane foam

[0046] The combined polyether and isocyanate are reacted at 18° C. according to the mass ratio of 1:1.25, and injected into a mold to obtain a rigid polyurethane foam insulation material for refrigerators.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com