Polyurethane foam plastic insulation material for container and preparation method thereof

A foamed plastic and thermal insulation material technology, applied in the field of polyurethane, can solve the problems of poor low temperature dimensional stability, high foam material injection volume and high thermal conductivity, and can shorten the mold opening time, reduce the thermal conductivity and lower the reaction temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The polyurethane foam insulation material for containers is composed of component A and component B, and the weight ratio of component A to component B is 1:1.05, in which:

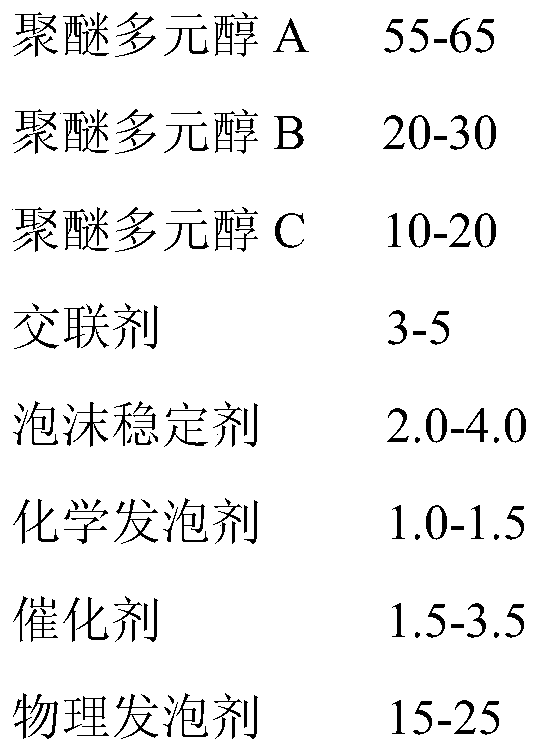

[0034] The component A is, in parts by weight:

[0035]

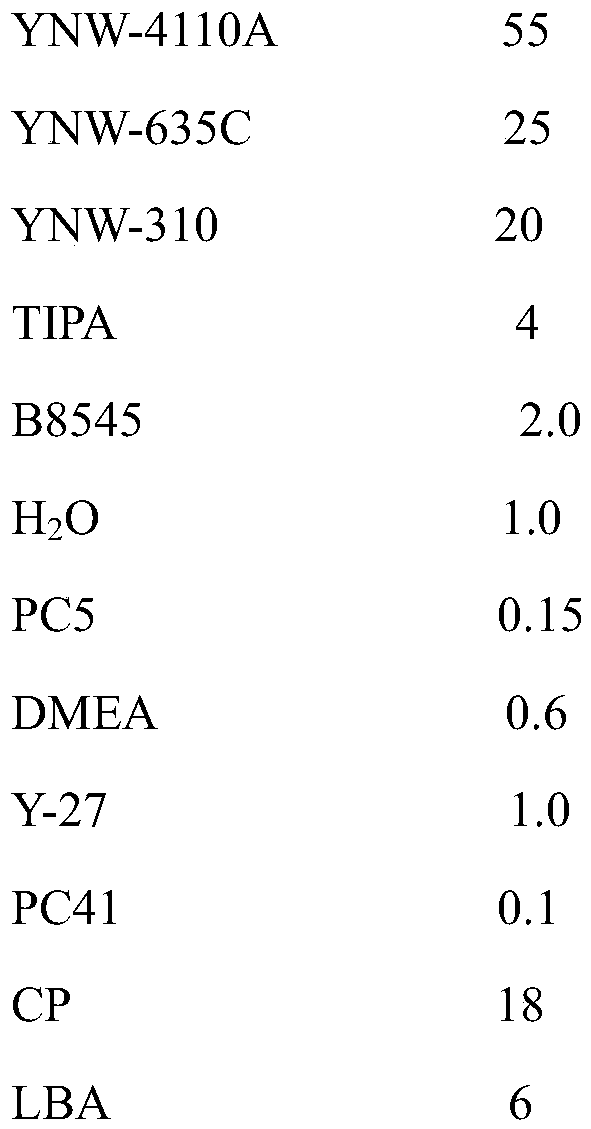

[0036] During preparation, the weighed polyether polyol A, polyether polyol B, polyether polyol C and crosslinking agent are added to the reaction kettle and stirred, and then the weighed physical foaming agent is fully mixed according to the ratio. Add the weighed foam stabilizer, catalyst, chemical blowing agent, and fully mixed physical blowing agent to the reaction kettle, and stir for 1.0 hour at room temperature to obtain component A; combine component A and isocyanate (PM200) according to The weight ratio is 1:1.05 and the mixture is uniformly mixed and reacted to prepare a polyurethane foam insulation material for containers.

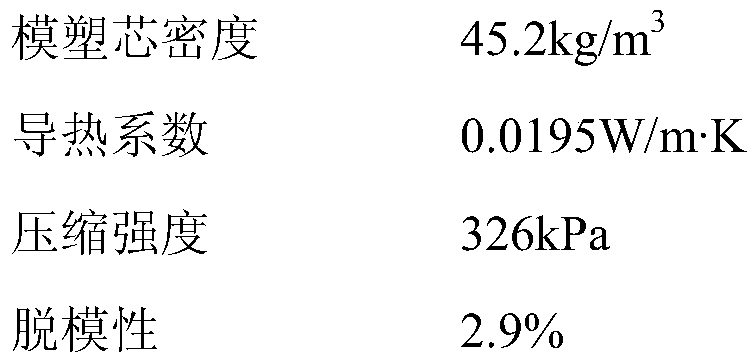

[0037] The specific indicators are as follows:

[0038]

[0039] Dimensional stability

[0040] -30℃, 24h: -0.22%

...

Embodiment 2

[0044] The polyurethane foam insulation material for containers is composed of component A and component B, and the weight ratio of component A to component B is 1:1.1, in which:

[0045] The component A is, in parts by weight:

[0046]

[0047] During preparation, the weighed polyether polyol A, polyether polyol B, polyether polyol C and crosslinking agent are added to the reactor and stirred, and then the weighed physical foaming agent is fully mixed according to the proportion. Add the weighed foam stabilizer, catalyst, chemical blowing agent, and fully mixed physical blowing agent to the reaction kettle, and stir for 1.5 hours at room temperature to obtain component A; combine component A and isocyanate (M20S) according to The weight ratio of 1:1.1 is mixed evenly and reacted to prepare a polyurethane foam insulation material for containers.

[0048] The specific indicators are as follows:

[0049]

[0050] Dimensional stability

[0051] -30°C, 24h: -0.26%

[0052] 100°C, 24h: 0.33...

Embodiment 3

[0055] The polyurethane foam insulation material for containers is composed of component A and component B, and the weight ratio of component A to component B is 1:1.15, in which:

[0056] The component A is, in parts by weight:

[0057]

[0058] During preparation, the weighed polyether polyol A, polyether polyol B, polyether polyol C and crosslinking agent are added to the reactor and stirred, and then the weighed physical foaming agent is fully mixed according to the proportion. Add the weighed foam stabilizer, catalyst, chemical blowing agent, and well-mixed physical blowing agent to the reaction kettle, and stir at room temperature for 1.0 hour to obtain component A; combine component A and isocyanate (M20S) according to The weight ratio is 1:1.5 and the mixture is evenly mixed and reacted to prepare a polyurethane foam insulation material for containers.

[0059] The specific indicators are as follows:

[0060]

[0061] Dimensional stability

[0062] -30℃, 24h: -0.29%

[0063] 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com