Compound scattered black dye high in color fastness

A composite dispersion and dyeing fastness technology, which is applied in dyeing methods, organic dyes, textiles and papermaking, etc., can solve the problems that the fastness of dye compositions needs to be improved, and achieve excellent coloring rate, good washing fastness, and reduce The effect of steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

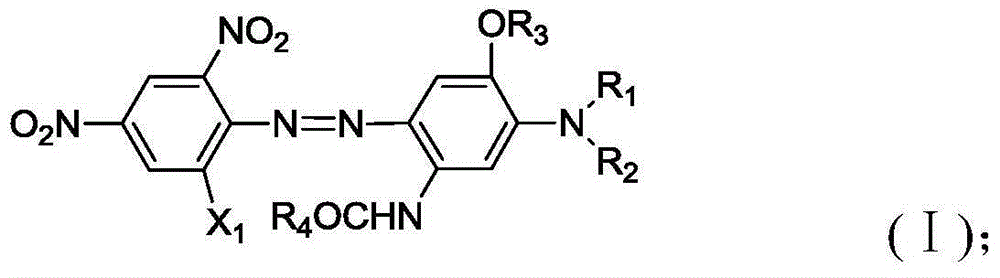

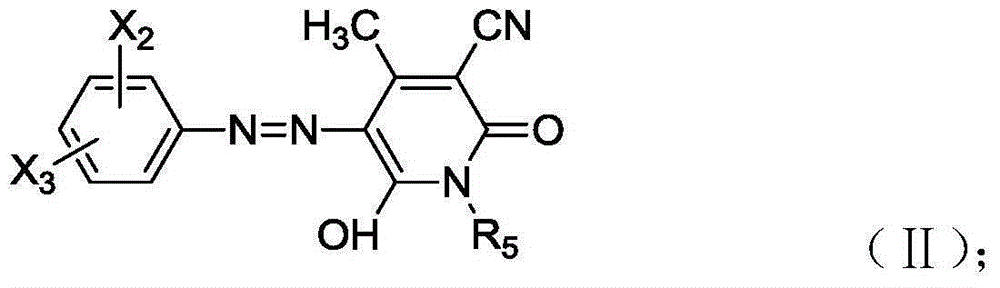

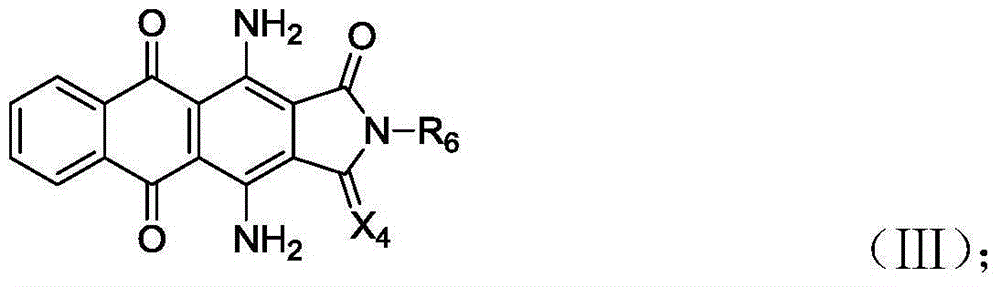

[0040] A kind of composite disperse black dyestuff of high color fastness, by component A shown in structural formula (I), component B shown in structural formula (II-1), component C shown in structural formula (III), structural formula ( Ⅳ) Component D and additive composition shown in:

[0041]

[0042]In terms of mass fraction, the mass fraction of component A is 4%, the mass fraction of component B is 14%, the mass fraction of component C is 12%, the mass fraction of component D is 23%, and the rest are auxiliary agents.

[0043] The preparation method of the composite disperse black dye is as follows: after mixing the components A to D according to the preset ratio, use a sand mill or The composite disperse black dye is obtained by micronizing with a pulverizing device such as a grinder.

Embodiment 2

[0045] Adopt the method identical with embodiment 1 to prepare composite disperse black dyestuff, but choose the dyestuff with following structural formula as component A:

[0046]

[0047] The amount of each component was not changed.

Embodiment 3

[0054] Adopt the method identical with embodiment 1 to prepare composite disperse black dye, but choose the dyestuff with following structural formula respectively as component C:

[0055]

[0056] The amount of each component was not changed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com