Windproof and dust suppressant agent for coal yard and preparation method thereof

A dust suppressant and coal yard technology, applied in the field of environmental pollution control, can solve problems such as high water consumption, lower boiler thermal efficiency, and high investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

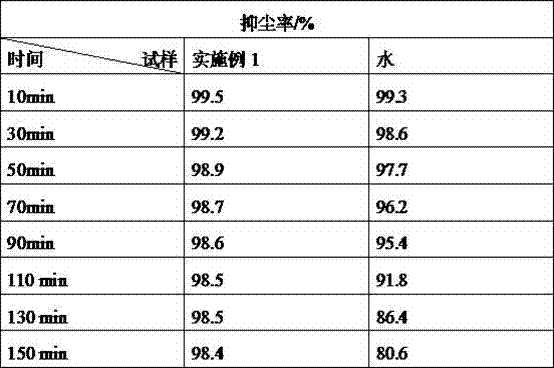

Examples

Embodiment 1

[0038] (1) Add 0.5 parts of xanthan gum and maltodextrin (the ratio of xanthan gum to maltodextrin is 3:1) into 50 parts of water, stir and dissolve rapidly at 50°C;

[0039] (2) Add 5 parts of glycerol and propylene glycol (the ratio of glycerol to propylene glycol is 1:2) into the mixture in step (1) and stir evenly;

[0040] (3) Add 2 parts of polyvinyl alcohol to 50 parts of water, stir and dissolve at 90°C, add it to the mixture in step (2) after cooling;

[0041] (4) Add 3 parts of diethylene glycol, 1.7 parts of sodium diacetate, and 0.8 parts of OP-10 to the mixture in step (3), and stir well to obtain the coal yard windproof and dust suppressant solution.

Embodiment 2

[0043] (1) Add 0.1 part of xanthan gum and maltodextrin (the ratio of xanthan gum to maltodextrin is 3:1) into 50 parts of water, stir rapidly at 50°C to dissolve;

[0044] (2) Add 3 parts of glycerol and propylene glycol (the ratio of glycerol to propylene glycol is 1:2) into the mixture in step (1) and stir evenly;

[0045] (3) Add 0.5 parts of polyvinyl alcohol to 50 parts of water, stir and dissolve at 90°C, add it to the mixture in step (2) after cooling;

[0046] (4) Add 1.5 parts of diethylene glycol, 1.5 parts of sodium diacetate, and 0.5 parts of OP-10 to the mixture in step (3), and stir well to obtain the coal yard windproof and dust suppressant solution.

Embodiment 3

[0048] (1) Add 0.8 parts of xanthan gum and maltodextrin (the ratio of xanthan gum to maltodextrin is 3:1) into 50 parts of water, stir rapidly at 50°C to dissolve;

[0049] (2) Add 7 parts of glycerol and propylene glycol (the ratio of glycerol to propylene glycol is 1:2) into the mixture in step (1) and stir evenly;

[0050] (3) Add 4 parts of polyvinyl alcohol to 50 parts of water, stir and dissolve at 90°C, add it to the mixture in step (2) after cooling;

[0051] (4) Add 5.5 parts of diethylene glycol, 2 parts of sodium diacetate, and 1 part of OP-10 to the mixture in step (3), and stir well to obtain the coal yard windproof and dust suppressant solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com