Photoconversion material for enhancing energy efficiency of solar cells and preparation method thereof

A solar cell and light conversion technology, which is applied in the directions of luminescent materials, chemical instruments and methods, circuits, etc., can solve the problem that the light conversion efficiency of silicon-based solar cells cannot be improved, and achieve the effect of improving the light conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

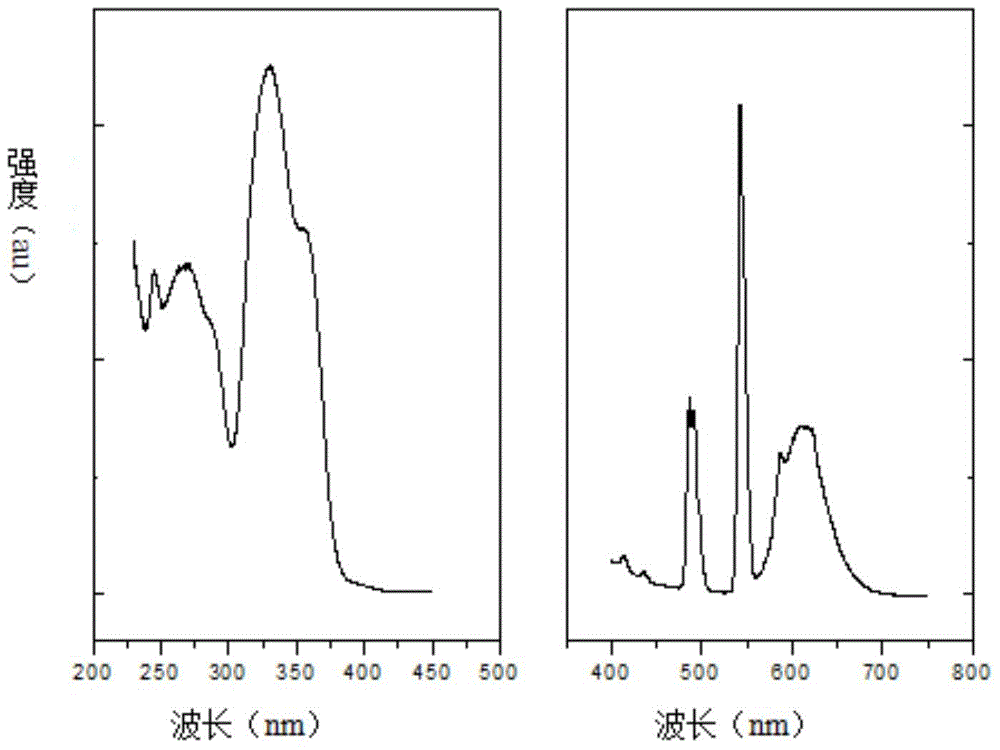

[0035] Convert a 200-400nm ultraviolet light into a green or orange fluorescent material at 500-650nm, and its chemical composition is aL.bM.cN:dQ(L=Ca, Sr, M=BO 3 ,N=SiO 2 , Q=one or more compounds of La, Ce, Tb, Gd, Mn), a=1, b=5.9, c=0.1, d=0.5. That is, the chemical composition is Sr 0.1 Ca 0.9 B 5.9 Si 0.1 La 0.43 Ce 0.03 Tb 0.01 Gd 0.01 mn 0.02 o 10.79 , according to the above chemical composition, 90 g of CaCO 3 , 14.762 g SrCO 3 , 364.67 g H 3 BO 3 , 6 grams of SiO 2 , 70.05 g La 2 o 3 , 5.175 g CeO 2 , 1.87 g Tb 4 o 7 , 1.81 grams of Gd 2 o 3 , 1.74 g MnO 2 Mix in a closed container; then place the mixture at 95% N 2 -5%H 2 Under the atmosphere, keep warm in a synthetic furnace at 1300°C for 6 hours, cool, crush and classify, and sieve to obtain the photoconversion material. The excitation and emission spectra are as follows: figure 1 shown.

[0036] The above 12% (mass ratio %) light conversion material is added to the high-transmission orga...

Embodiment 2

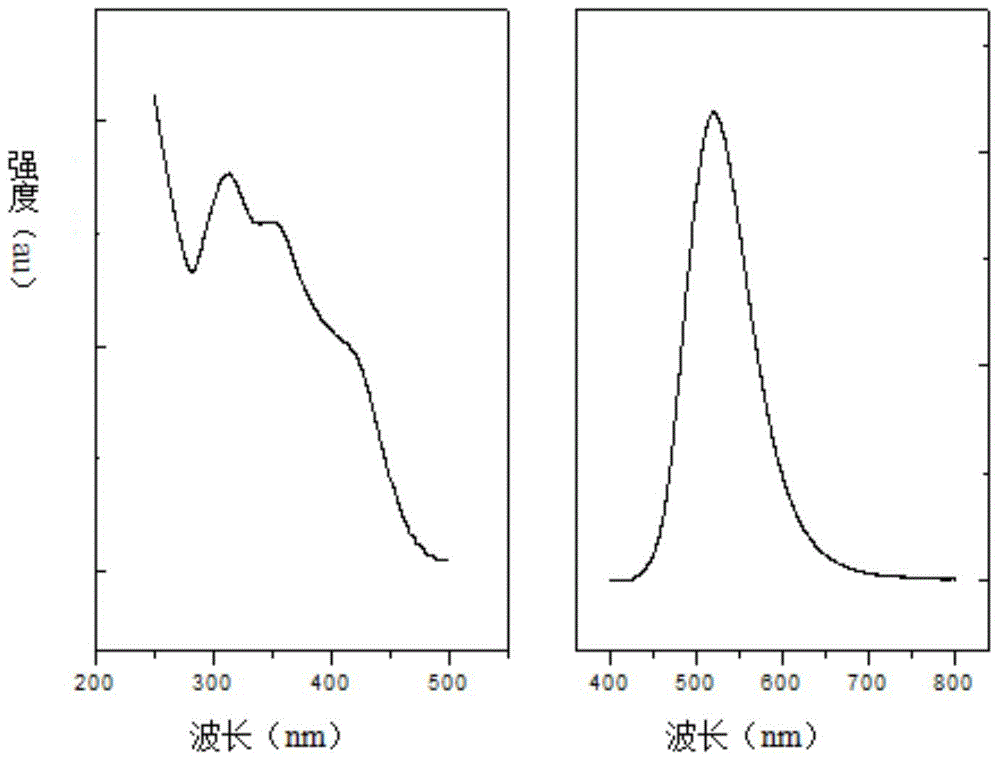

[0038] Convert a 200-400nm ultraviolet light into a green or orange fluorescent material with a wavelength of 500-650nm, and its chemical composition is aL.bM.cN:dQ(L=Li, Na, M=BO 3 ,N=Al 2 o 3 , Q=Y, Lu, Ce, one or more compounds), a=6, b=3, c=0.01, d=1, that is, the chemical composition is Li 5.9 Na 0.1 B 3 al 0.01 Y 0.9 Lu 0.05 Ce 0.05 o 9.03 , according to the above chemical composition, 217.95 g of Li 2 CO 3 , 5.3 g Na 2 CO 3 , 104.43 g B 2 o 3 , 0.51 g Al 2 o 3 , 101.56 g Y 2 o 3 , 8.625 g CeO 2 , 9.9485 g Lu 2 o 3 Mix in a closed container; then place the mixture at 95% N 2 -5%H 2 Under the atmosphere, keep warm in a synthetic furnace at 850°C for 12 hours, cool, crush and classify, and sieve to obtain the photoconversion material. The excitation and emission spectra are as follows: figure 2 shown. The above 10% (mass ratio %) light conversion material is added to the high-transmission organic polymer material PS, and then prepared by injection ...

Embodiment 3

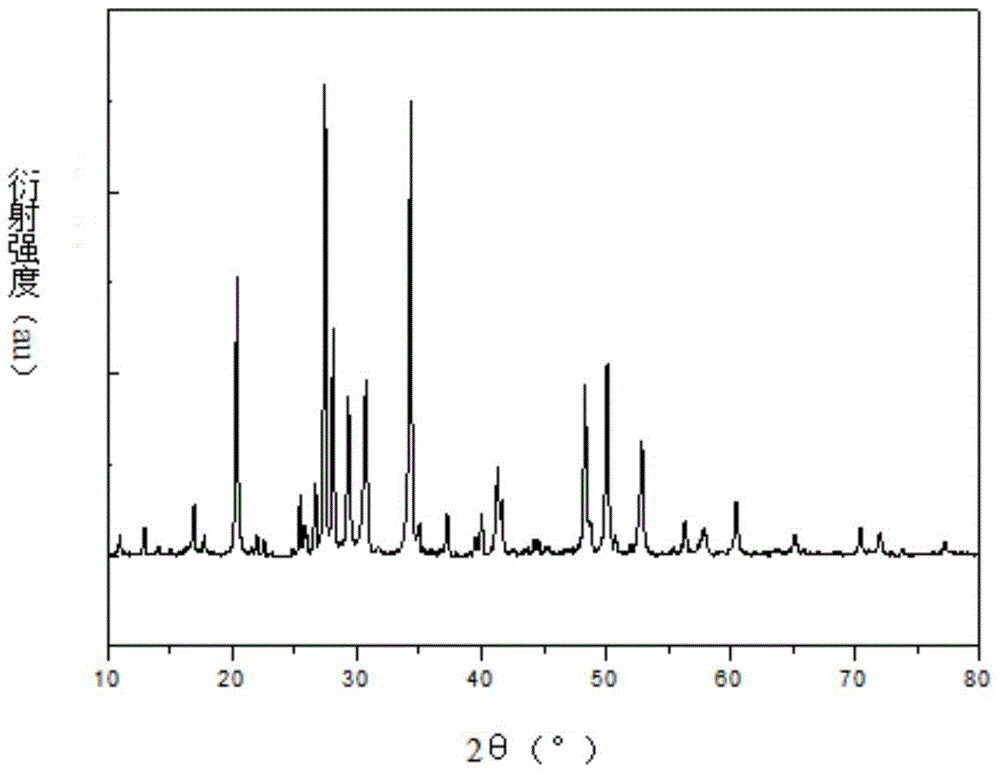

[0041] Convert a 200-400nm ultraviolet light into a fluorescent material of about 500-650nm green and orange, and its chemical composition is aL.bM.cN:dQ(L=Ca, Sr, Ba, M=BO 3 ,N=SiO 2 , Q=Y, one or more Eu compounds), a=5.6, b=0.2, c=1.8, d=0.4, that is, the chemical composition is Ca 0.1 Sr 5.2 Ba 0.3 B 0.2 Si 1.8 Y 0.2 Eu 0.2 o 10.1 , according to the above chemical composition, 10 g of CaCO 3 , 768.82 grams of SrCO 3 , 59.19 g BaCO 3 , 12.36 g H 3 BO 3 , 108 g SiO 2 , 22.51 g Y 2 o 3 , 35.19 grams of Eu 2 o 3 Mix in a closed container, mix in a closed container; then put the mixture in 95% Ar-5% H 2 Under the atmosphere, keep warm in a synthesis furnace at 1500°C for 6 hours, cool, crush and classify, and sieve to obtain the photoconversion material. The excitation and emission spectra are as follows: Figure 4 shown. Mix in a closed container; then place the mixture at 95% N 2 -5%H 2 Under the atmosphere, keep warm in a synthetic furnace at 850°C for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com