A method of using distiller's grains as raw material for high-temperature anaerobic fermentation to produce biogas

A technology for producing biogas and raw materials, which is applied in fermentation, waste fuel, biological sludge treatment, etc., and can solve problems such as shortages and inability of distiller's grains to process energy resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

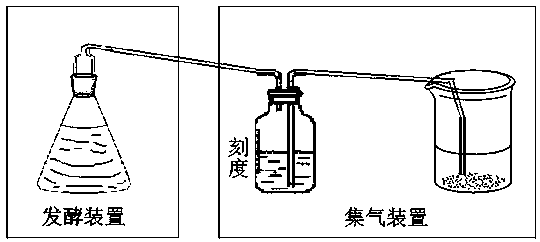

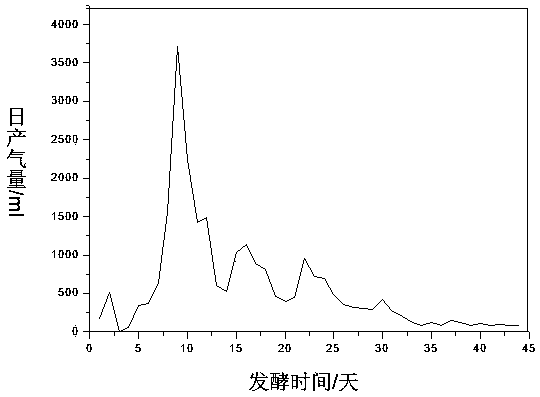

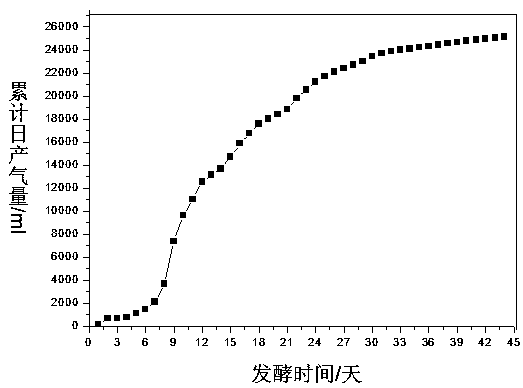

[0037] Specific implementation mode 1: as attached figure 1 , first accurately weigh 300 g of distiller’s grains, transfer it to a 2000 ml conical flask, then add 245 ml of inoculum, add water to the 1500 ml of the conical flask, stir evenly, adjust the pH to 8.02 with 1mol / L NaOH solution, Plug a rubber stopper with an air guide tube, and use a glue gun to seal the connection between the rubber stopper and the Erlenmeyer flask, connect the air guide tube to the gas collection device, and place the Erlenmeyer flask in a shaker at 55°C. The rotational speed was set at 120 rpm, and the shake was set for 3 minutes per hour. Do three sets of repetitions. A blank test was performed with a fermentation broth containing only the inoculum and water. The amount of biogas produced is recorded by drainage gas collection method every day, the gas composition of biogas is measured by gas chromatograph, and the gas collection system is returned to water. Fermented for 44 days, ended the ...

specific Embodiment approach 2

[0038] Specific embodiment 2: Put distiller's grains in shakers at normal temperature of 25°C and medium temperature of 38°C to carry out fermentation and gas production experiments. The gas production effect at high temperature is obviously better than that at medium temperature and normal temperature.

[0039]

specific Embodiment approach 3

[0040] Specific embodiment 3: The TS concentration of distiller's grains is respectively set as 1%, 2%, 2.5%, 3%, 3.5%, 4%, and 5%, and then anaerobic fermentation gas production experiment is carried out at high temperature. Other experimental steps are as follows: As shown in Embodiment 1, the result is as follows Figure 4 It can be seen from the results that when the TS concentration of distiller's grains is 2%~3.5%, the gas production effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com