Variable temperature gas inflation system and control method for sapphire single crystal furnace

A sapphire single crystal furnace and gas filling system technology, which is applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of manpower and equipment waste, crystal cold cracking, and long growth cycle, so as to improve the yield rate, The effect of reducing the late cooling time and shortening the growth cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

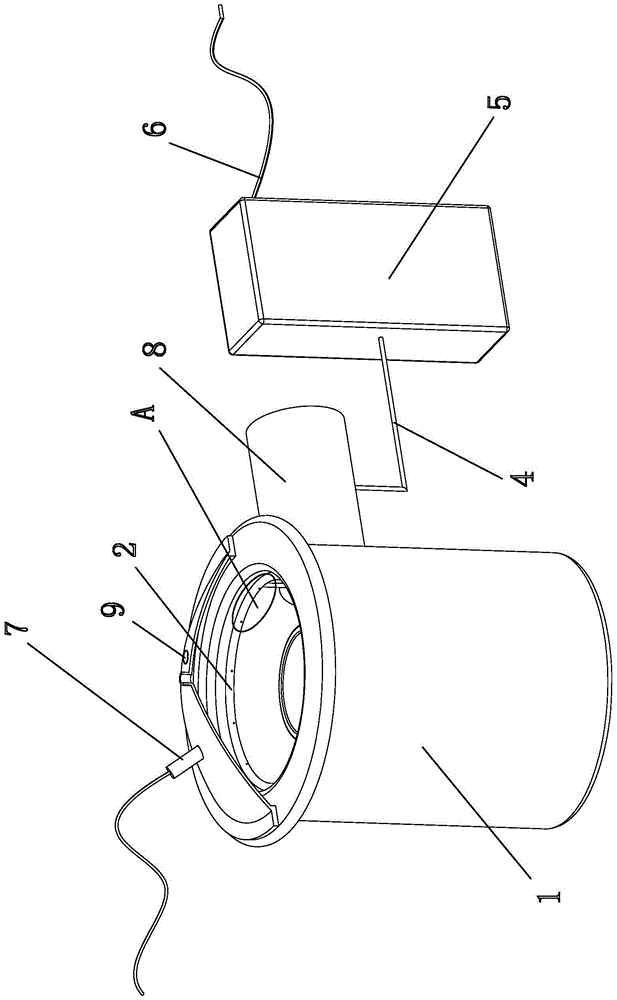

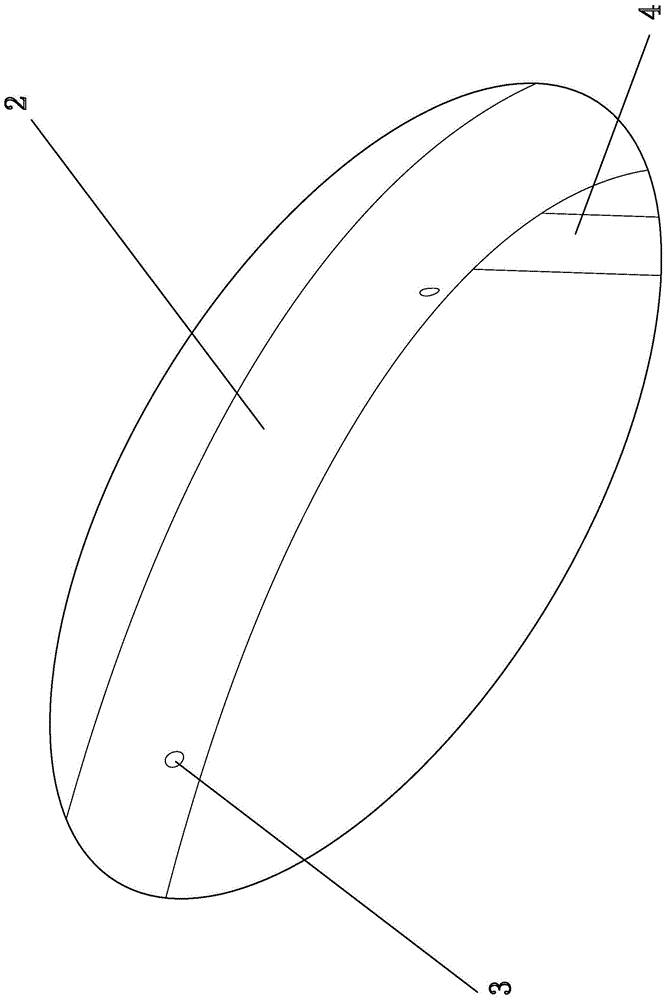

[0029] Such as Figures 1 to 2 A variable temperature gas charging system for a sapphire single crystal furnace includes a furnace body 1, a variable temperature gas ring pipe 2 is arranged on the furnace body 1, and several temperature variable gas ring pipes are arranged on the variable temperature gas ring pipe 2. Gas holes 3, a gas delivery pipe 4 is connected to the variable temperature gas ring pipe 2, and one end of the gas delivery pipe 4 extends out of the furnace body 1 and is connected to the gas heater 5, and at the gas heater 5 inlet end Connected with intake pipe 6.

[0030] In the present invention, an infrared thermometer 7 is provided on the furnace body 1 .

[0031] In the present invention, a connection hole is provided at the bottom of the exhaust pipe 8 of the furnace body 1, and the gas delivery pipe 4 extends out ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com