Fiber temporary plugging turnaround fracture method capable of improving low permeability tight sandstone oil and gas well production capacity

A technology for tight sandstone and well productivity, applied in the field of oil and gas well fracturing, which can solve the problems of not being easy to turn to fractures, increasing the area of oil and gas drainage after pressure, and easy breakthrough of fractures, etc., achieving obvious construction effects, flexible and adjustable construction, and optimized construction The effect of the parameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment provides a fiber temporary plugging diversion fracturing method for improving the productivity of low-permeability tight sandstone gas wells, including the following steps:

[0036] Step 1) According to single well logging, mud logging data, reservoir stress data, lateral distribution of reservoir sandstone and development of micro-fractures, determine and select the wells and layers to implement fiber temporary plugging and diversion fracturing.

[0037] Among them, it is judged that the wells and formations selected for temporary fiber plugging and diversion fracturing meet the following conditions:

[0038] (1) The stress difference between the maximum horizontal principal stress and the minimum horizontal principal stress of the reformed sandstone reservoir is less than 9MPa;

[0039] (2) The micro-fractures in the reformed sandstone reservoir are well developed, and the average number of micro-fractures is greater than 0.5 per meter of reservoir thi...

Embodiment 2

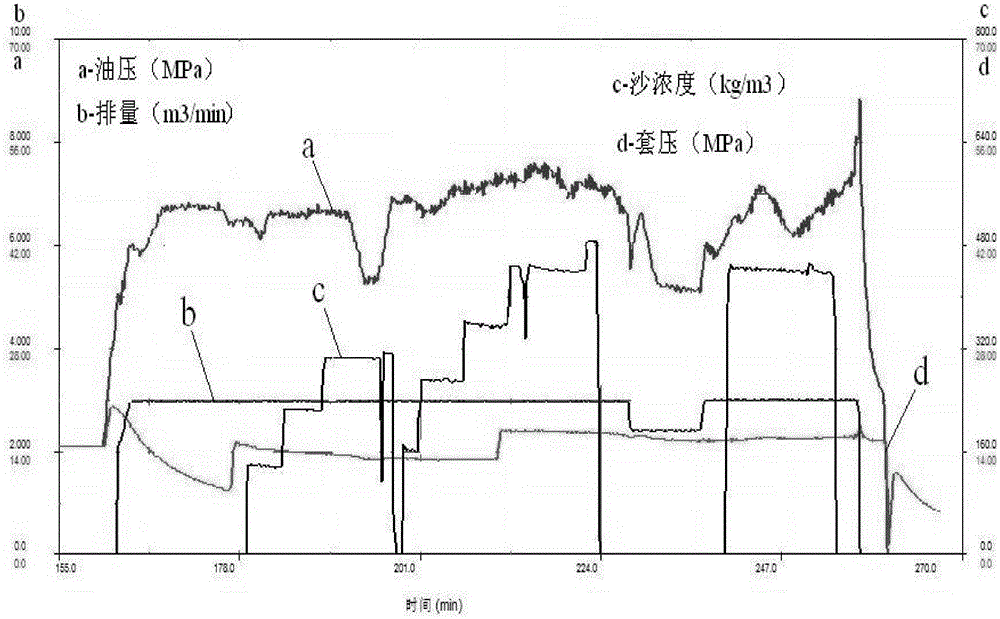

[0055] On the basis of Example 1, this example takes Well Sudong A as an example. This well is a gas field development well. It is a typical low-permeability tight sandstone gas reservoir with multiple thin layers. There are gas layers, gas-bearing layers, and gas-bearing layers. There are 6 sub-layers in the water layer. Based on a comprehensive analysis of the logging data of the well and the development of the block, the fracturing interval is selected as the mountain 1 air layer. In order to effectively stimulate the reservoir of this well, the fiber temporary plugging diversion fracturing process was designed.

[0056] Specific steps;

[0057] Step 1) Evaluate the Well Hill 1 Whether the gas layer is suitable for fiber temporary plugging and turning to fracturing: the block mountain 1 The average stress difference between the maximum horizontal principal stress and the minimum horizontal principal stress of the formation is 6MPa. Micro-fractures are relatively develope...

Embodiment 3

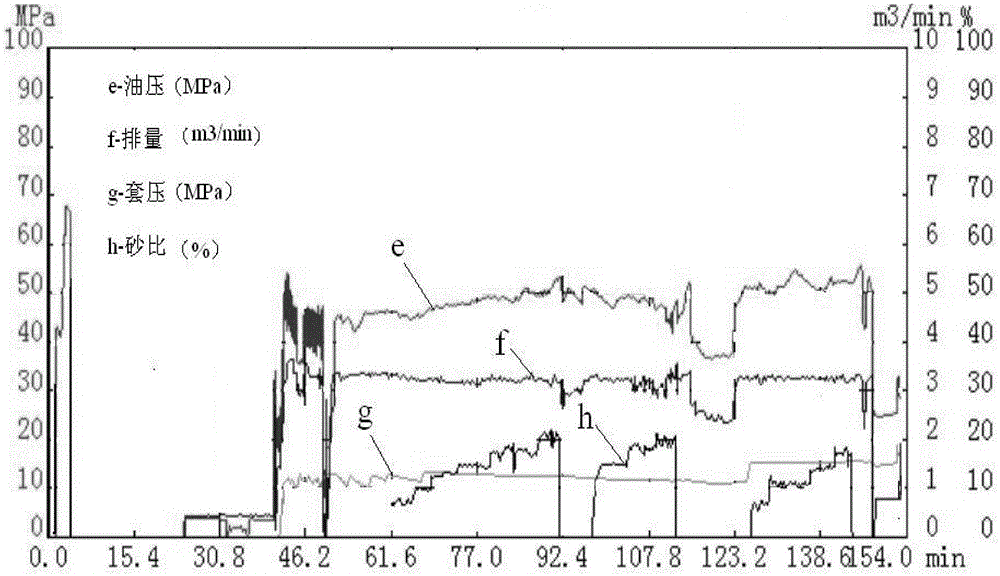

[0120] On the basis of Example 1, this example takes Well Sudong B as an example. This well is a gas field development well, a typical low-permeability tight sandstone gas layer with multiple thin layers. 1 ,box 8下 The two sections were transformed by partial pressure of the mechanical fixed string, and the geological data of the well were comprehensively evaluated. It is considered that the lower part of the well is 1 Layers can implement fiber temporary plugging and diversion fracturing technology.

[0121] the well hill 1 Section construction curves such as image 3 As shown, the construction displacement is 3.0-3.4m 3 / min, add sand to fractures for the first time after the front hydraulic pressure opens the formation, and add proppant 10m 3 Finally, perform the first fiber temporary plugging, add 30kg of fiber diverting agent at 15kg / min, and the pressure suddenly increases from 48MPa to 54MPa, perform the second fiber temporary plugging after the replacement, add 160...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com