A self-priming gravity wave pump

A self-priming, gravity technology, applied in hydroelectric power generation, ocean energy power generation, engine components, etc., can solve the problems of complex anchoring system, high cost and maintenance cost, large volume of wave-surfing device, etc., to achieve convenient deployment, Easy maintenance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below with reference to the accompanying drawings and examples.

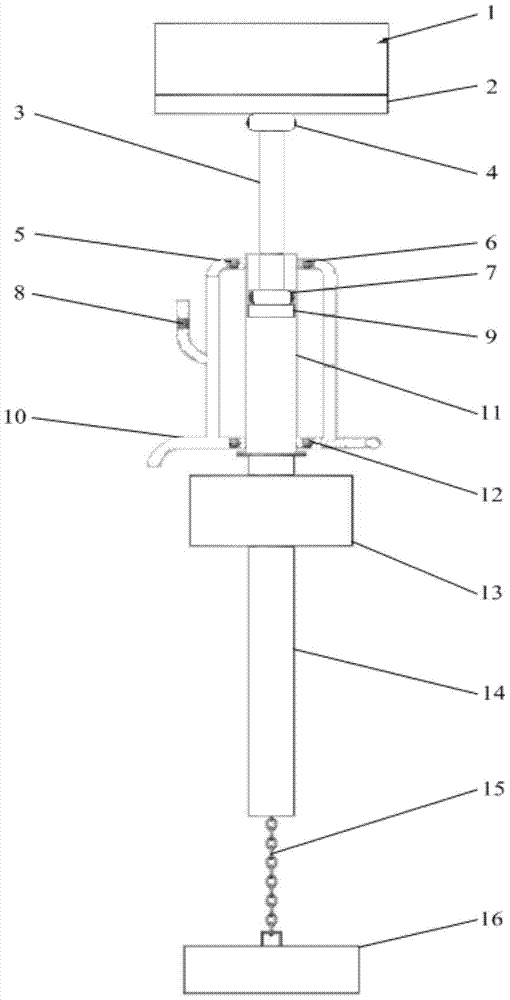

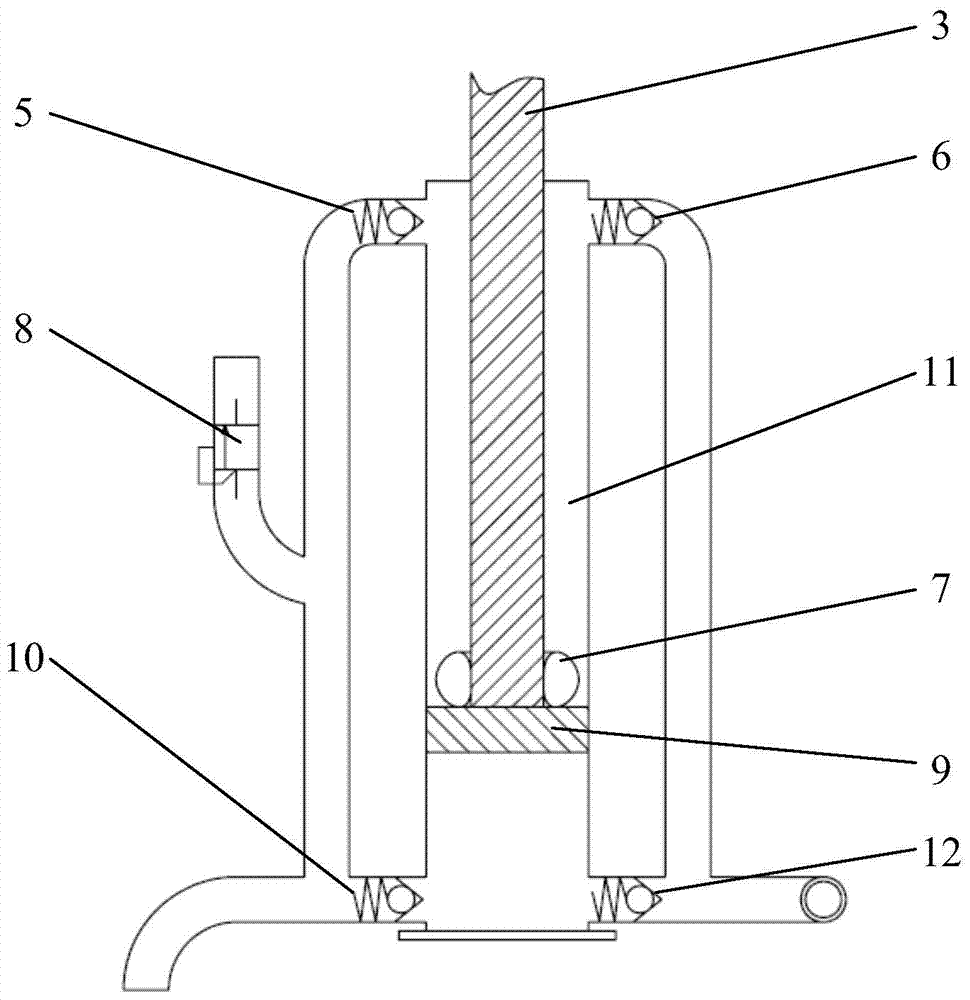

[0015] A self-priming gravity wave pump device provided in this embodiment, such as figure 1 Shown, comprise surface floating body 1, counterweight 2, piston rod 3, one-way valve, overflow valve 8, piston 9, pump body 11, underwater floating body 13, support buoy 14, anchor chain 15 and anchor 16.

[0016] The pump body 11 is a sealed cylinder, and its upper and lower ends are respectively opened with two symmetrical water holes along the central axis. The upper and lower water holes on the same side of the pump body are connected by pipelines as water inlet and outlet respectively. For the water pipeline, the two water holes at the lower end are connected to the outside, and a check valve is installed in the pipeline at the water hole; a section of pipeline is connected to the outlet pipeline of the pump barrel as an overflow pipeline, and an overflow val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com