Stainless steel baking oven

A stainless steel and oven technology, applied in drying, drying machine, local stirring dryer, etc., can solve the problems of high labor intensity and low production efficiency of workers, and achieve low labor intensity, high production efficiency, and reliable sealing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

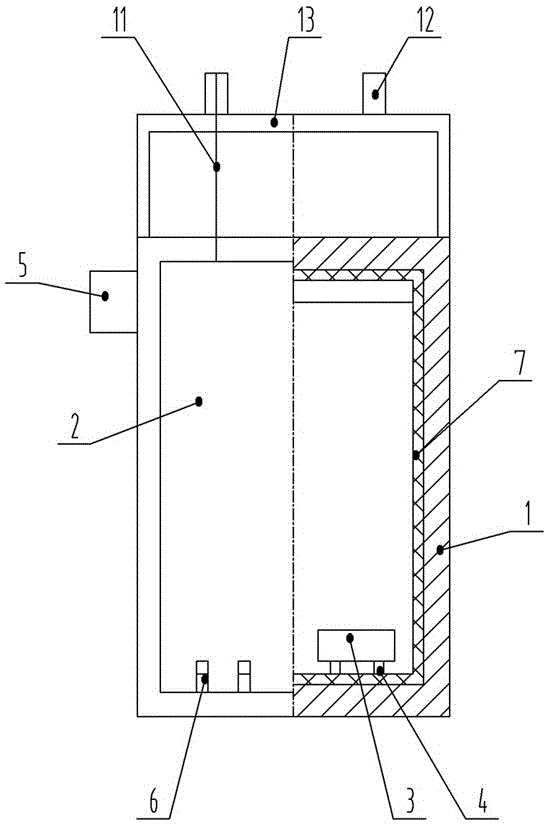

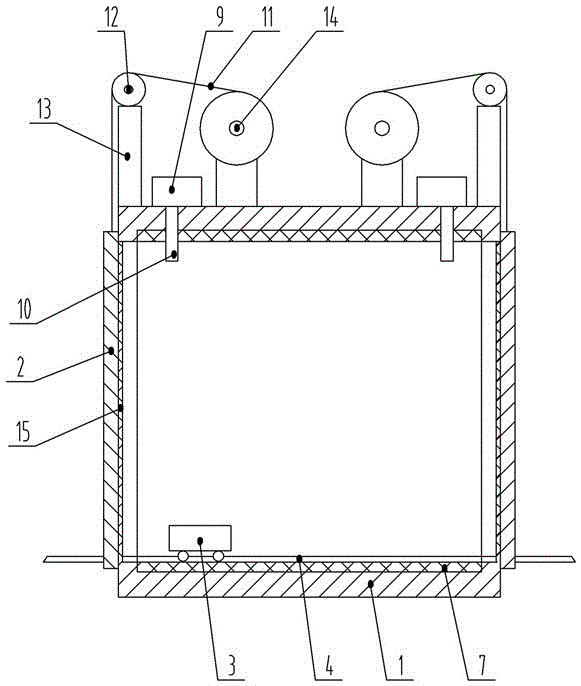

[0020] see Figure 1-2 , in the figure, the stainless steel oven of the present invention includes a stainless steel box body, a feed inlet and a discharge port are oppositely provided at both ends of the box body, a movable door 2 is respectively provided on the inlet and outlet and the discharge port, and a reciprocating door 2 is provided in the box body. The mobile trolley 3, the casters at the bottom of the trolley are slidingly matched with the corresponding parallel guide rails 4 provided at the bottom of the box body, and the box body is equipped with a controller 5 at the same time. The parallel guide rails extend outward from both ends of the box body, corresponding to the parallel guide rails, The bottom of the dodge door is matched with an avoidance groove 6, and an air curtain device 9 is respectively arranged on the top of both ends of the box body and behind the dodge door, and the air curtain device is provided with an air outlet 10 to communicate with the box b...

Embodiment 2

[0023] see figure 1 , 2 , in the figure, this embodiment is similar in structure to Embodiment 1, and the same numbers represent the same meaning, and the structurally identical parts will not be repeated here. The difference is that the movable door described in this embodiment is equipped with an automatic lifting device. The automatic lifting device includes slide rails, steel wire ropes 11, guide pulleys 12, brackets 13, and reels 14. The slide rails are located on both sides of the inlet and outlet of the box. There are two groups of pulleys, which are respectively placed on both sides of the dodge door, and the free end of the wire rope is connected with the dodge door. A sealing ring 15 is provided on the inner side of the movable door and the contact surface between the inlet and outlet of the box body. The movable door can be lifted and lowered automatically, which can reduce the labor intensity of workers and help improve production efficiency.

Embodiment 3

[0025] see figure 1 , 2 , in the figure, the structure of this embodiment is similar to that of Embodiment 1, and the same numbers represent the same meaning, and the same parts in the structure will not be repeated here. Plate 7 composition. There is an insulation layer on the box body to prevent heat loss and help to ensure a constant gradient temperature inside the box.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com