A quantum correlation autocollimator and angle measurement method

An autocollimator and quantum correlation technology, which is applied in the field of measurement, can solve the problems of mutual restriction between the range of angle measurement and the accuracy of angle measurement, miniaturization of the autocollimator, and high accuracy of angle measurement, so as to eliminate the influence of atmospheric turbulence and reduce the Cost and volume, high sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

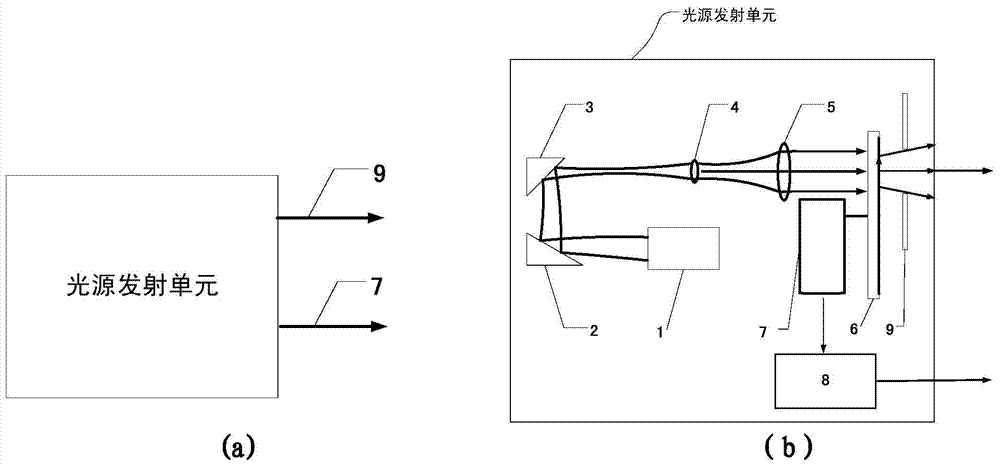

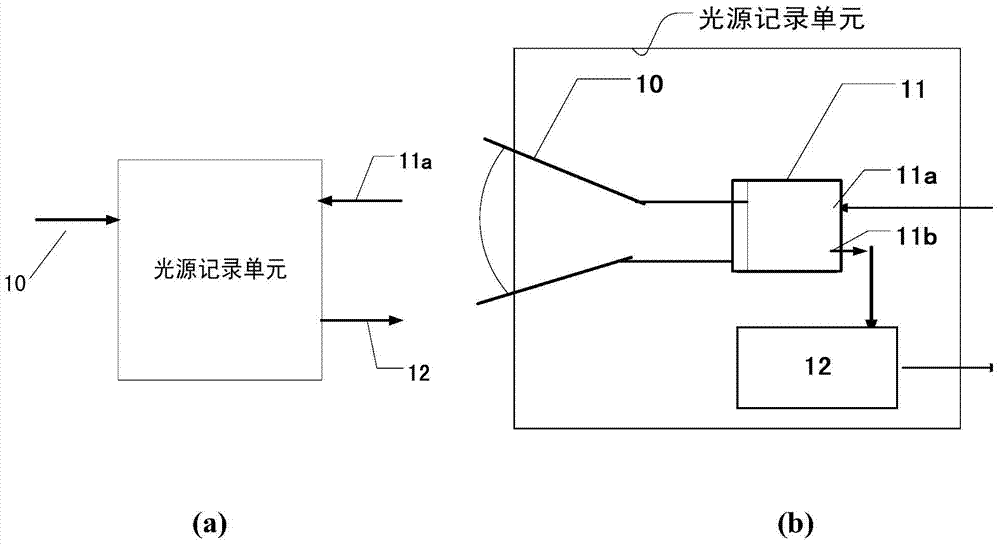

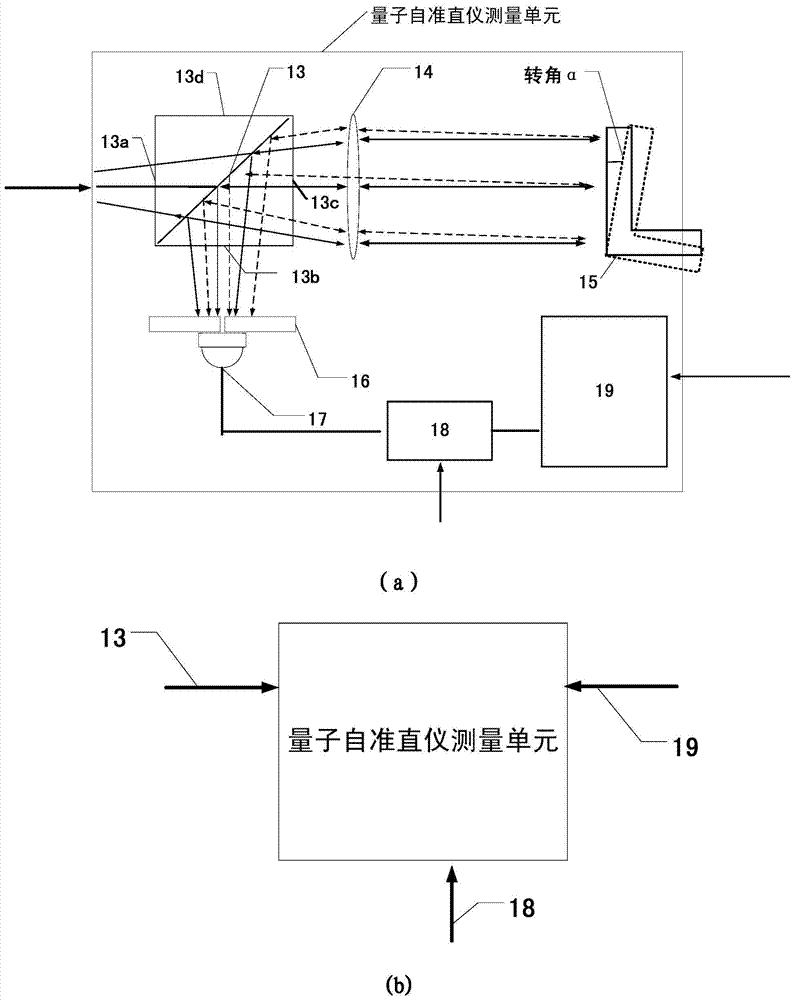

[0030] The invention discloses a quantum correlation autocollimator, such as figure 1 (a) and (b), figure 2 (a) and (b), as shown in (a) and (b) of Figure (3), include: a light source emitting unit, a light source recording unit, and a quantum autocollimator measuring unit;

[0031] The light source emitting unit includes a laser 1, a first reflector 2, a second reflector 3, a first lens 4, a second lens 5, a control unit 8, a stepping motor 7, a ground glass 6 and a first aperture 9;

[0032] The light source recording unit includes: a zoom lens 10, an industrial camera 11 and an image acquisition and storage unit 12;

[0033] Quantum autocollimator measurement unit includes: 50:50 beam splitter 13, third lens 14, third mirror 15, second diaphragm 16, photodetector 17, data acquisition card 18, data processing and display module 19 ;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com