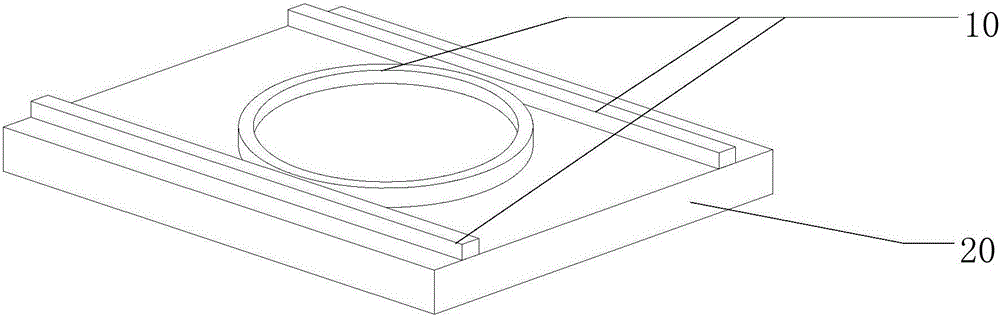

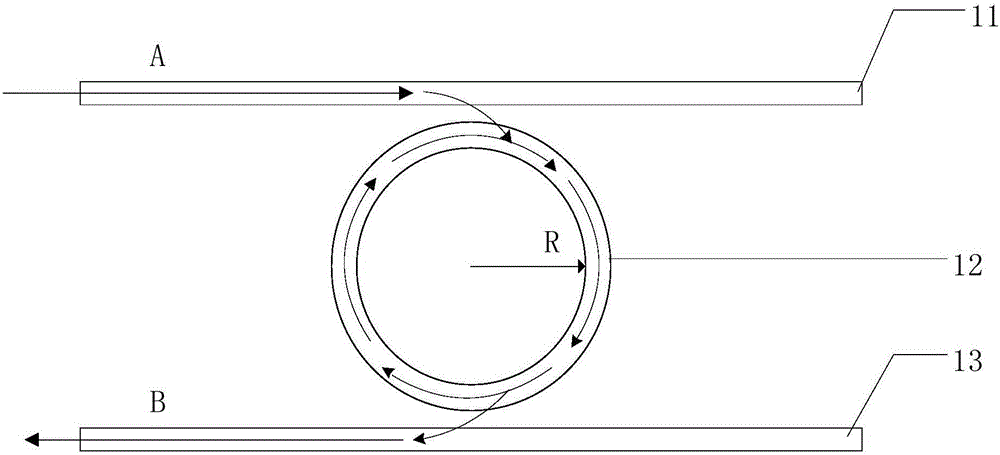

Testing device and method utilizing optical waveguide micro-ring resonator for testing methane concentration

A technology of microring resonator and methane concentration, which is applied in the measurement of phase influence characteristics, etc., can solve the problems affecting the accuracy of methane concentration test, and achieve reliable results and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

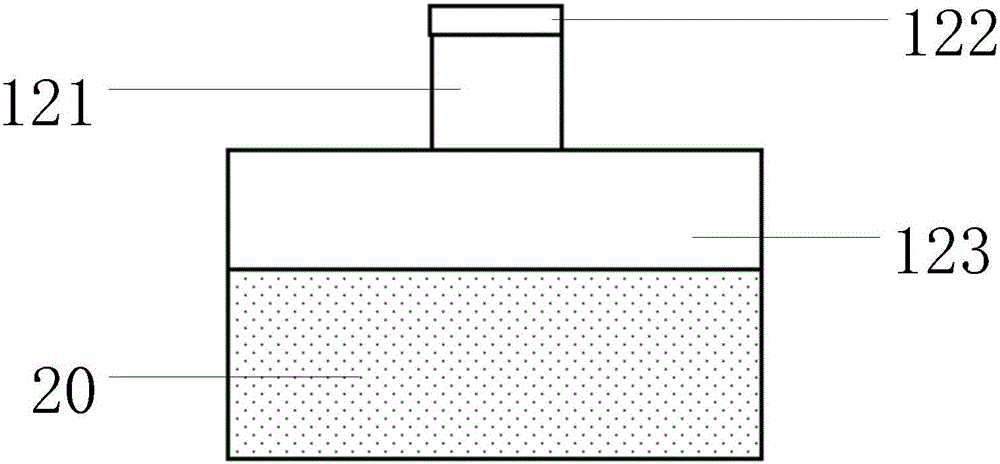

[0039] like Figure 4 As shown, the ring waveguide 12 of the microring resonator 10 in the first embodiment above can use a rectangular waveguide to facilitate the coating of the sensitive film 122 and the calculation of its effective refractive index. Wherein, the sensitive film 122 can be coated on one or more surfaces of the upper surface, the left side wall surface and the right side wall surface of the waveguide core 121, so that the sensitive film 122 can contact the methane gas in the air and generate covalent It works. Those skilled in the art can choose the position and method of coating the sensitive film 122 according to the actual situation, which is not limited in this application.

[0040] Preferably, the thickness of the sensitive film 122 is at least 0.5 μm. Specifically, when the optical signal is transmitted in the waveguide core 121 of the ring waveguide 12, the sensitive film 122 with a thickness greater than 0.5 μm can prevent the optical signal from pen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com