Application of nanometer MnOx and CrOx as peroxide mimic enzymes to hydrogen peroxide detection

A technology for the concentration of peroxide and hydrogen peroxide, which is applied in the field of nano-biochemical detection, can solve the problems of volatile inactivation of natural enzymes, high storage and use costs, and difficult purification, and can meet the requirements of production and application, and has high stability. , the effect of strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Synthesis of nano-manganese oxide

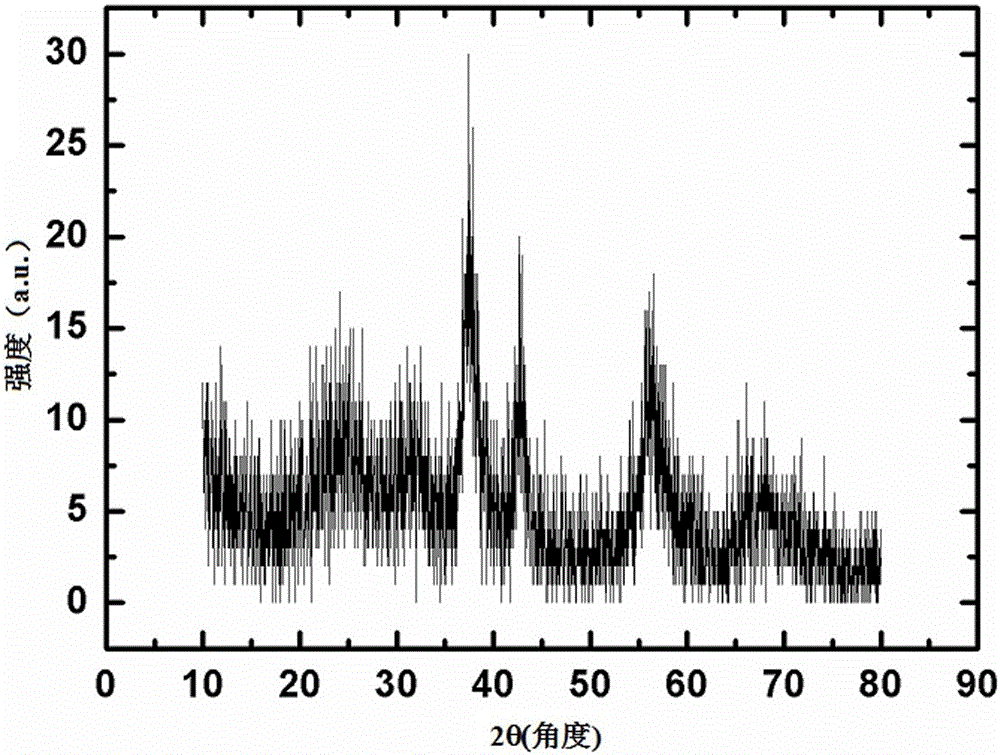

[0033] Add 20mL of 1mol / L manganese nitrate salt solution dropwise into 1mol / L sodium carbonate (Na 2 CO 3 ) solution (Na 2 CO 3 The amount is just enough to make the manganese nitrate precipitate completely), react at 50°C for 1h, wash with deionized water until neutral, dry at 100°C, and roast at 300°C for 3h to obtain nano-manganese oxide particles, manganese oxide is Mn 2 o 3 and a small amount of MnO 2 of mixed oxides.

[0034] figure 1 It is the XRD pattern of the nano-manganese oxide prepared by the present invention.

Embodiment 2

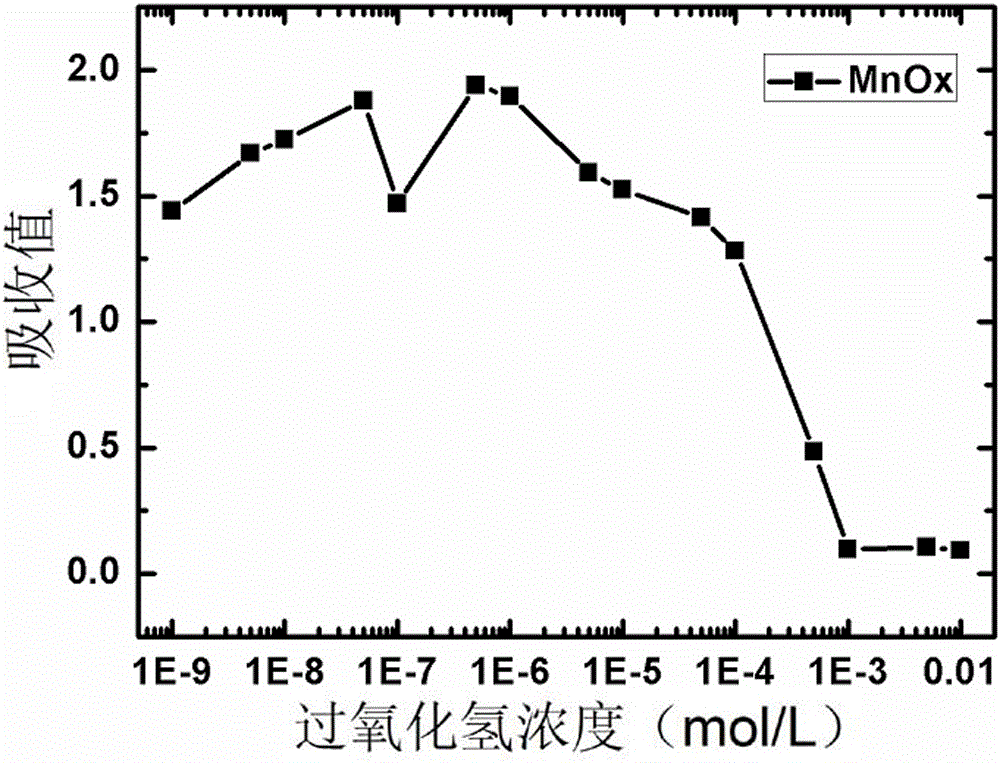

[0036] Nano-manganese oxide was used as a peroxide mimetic enzyme to determine the content of hydrogen peroxide.

[0037] Add 50ml, 1mg / ml manganese oxide solution, 20ml (5mg / ml) TMB solution to the solution, and then add different amounts of H 2 o 2 , such that H 2 o 2 The final concentration is 0, 10 -9 , 5×10 -9 , 10 -8 , 5×10 -8 , 10 -7 , 5×10 -7 , 10 -6 , 5×10 -6 , 10 -5 , 5×10 -5 , 10 -4 , 5×10 -4 , 10 -3 , 5×10 -3 , 10 -2 (mol / L). Add sodium acetate buffer solution (pH=7.0), so that the final volume of the solution to be tested is 200ml. After 30 min at room temperature, the absorbance of the solution was measured using a microplate reader.

[0038] figure 2 In order to use TMB as chromogen, nano-manganese oxide was used as peroxide mimetic enzyme to measure hydrogen peroxide content.

Embodiment 3

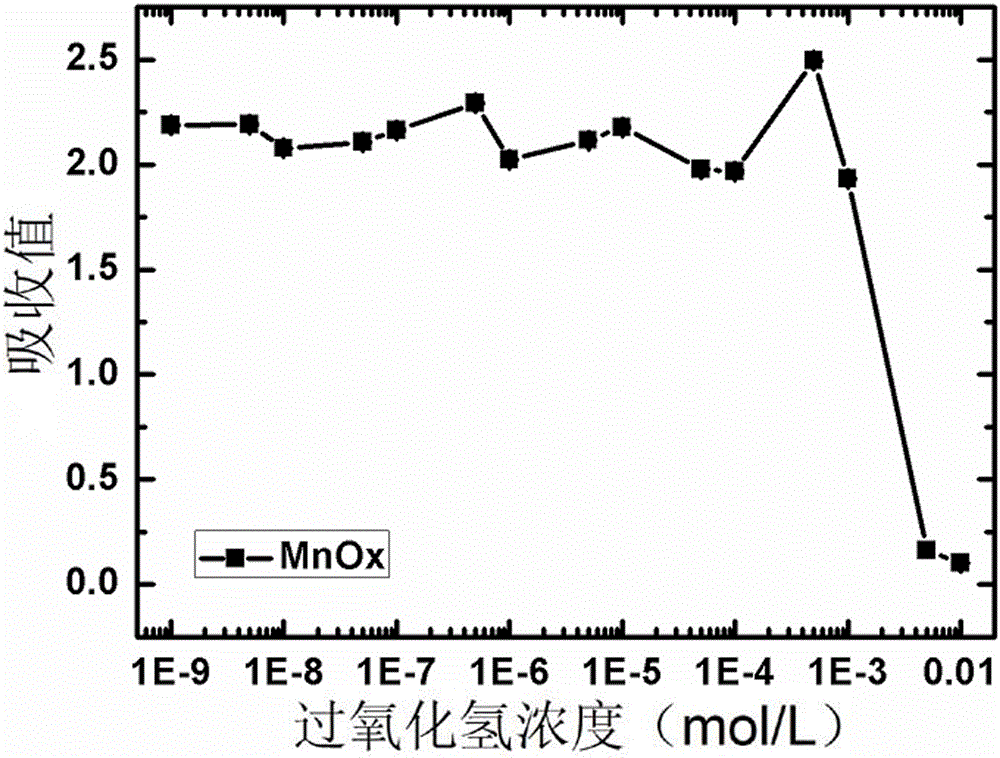

[0040] Nano-manganese oxide was used as a peroxide mimetic enzyme to determine the content of hydrogen peroxide.

[0041] Add 50ml, 1mg / ml manganese oxide solution, 20ml (5mg / ml) ABTS solution to the solution, and then add different amounts of H 2 o 2 , such that H 2 o 2 The final concentration is 0, 10 -9 , 5×10 -9 , 10-8 , 5×10 -8 , 10 -7 , 5×10 -7 , 10 -6 , 5×10 -6 , 10 -5 , 5×10 -5 , 10 -4 , 5×10 -4 , 10 -3 , 5×10 -3 , 10 -2 (mol / L). Sodium acetate buffer solution (pH=4.0) was added so that the final volume of the solution to be tested was 200ml. After 30 min at room temperature, the absorbance of the solution was measured using a microplate reader.

[0042] image 3 The catalytic activity diagram of nano-manganese oxide catalyzing hydrogen peroxide at room temperature using ABTS as color reagent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com