Panel and testing method of same

A technology of panel and test pad, applied in the field of panel and its testing, can solve the problem of high testing complexity of touch electrode layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

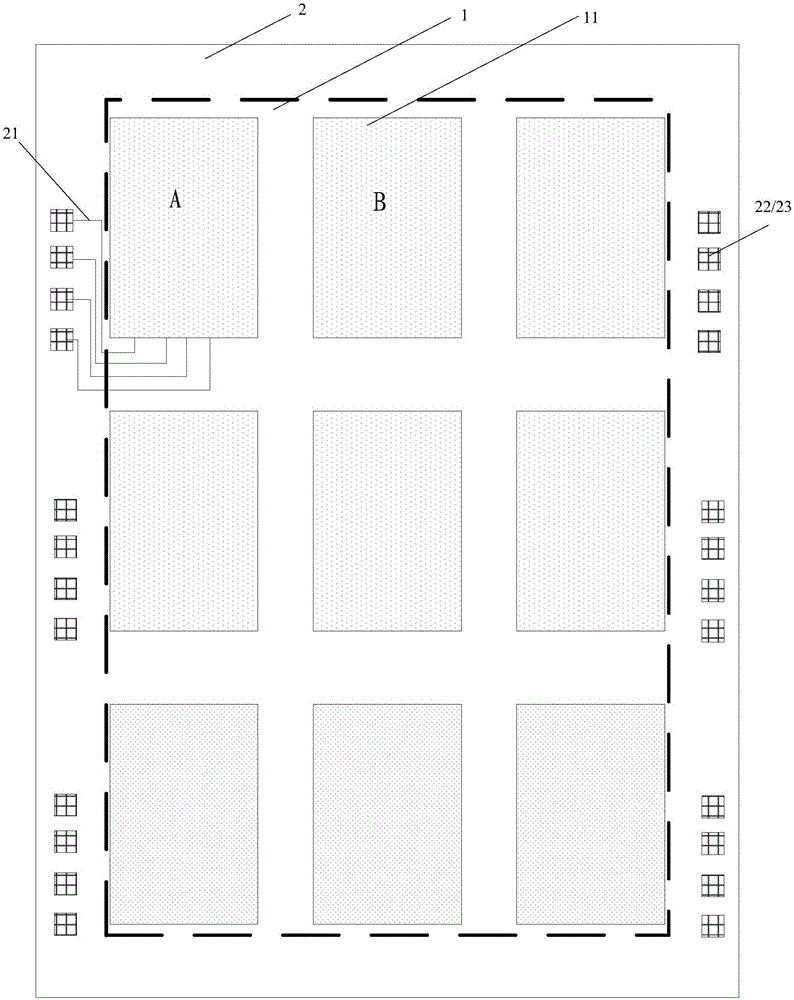

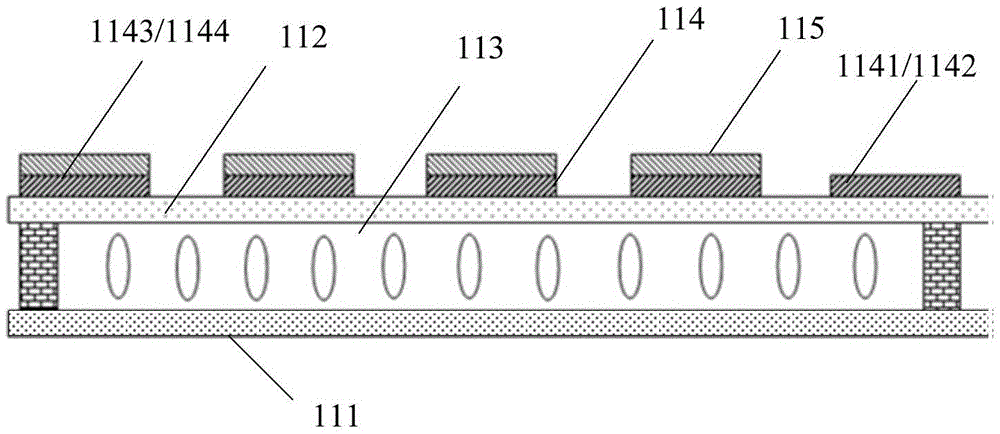

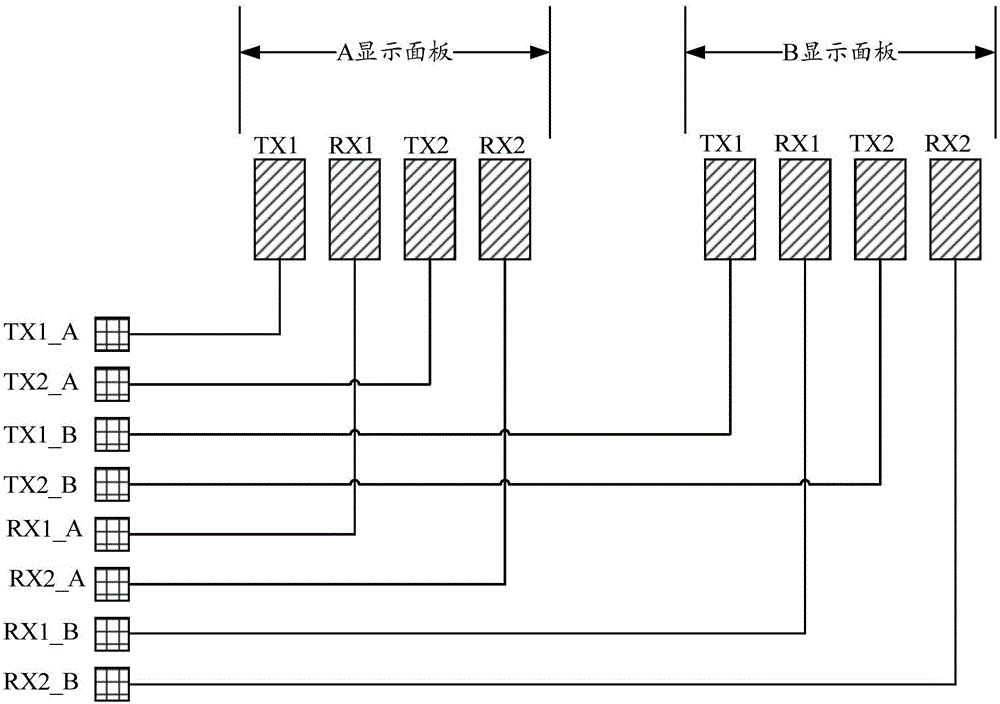

[0041] In order to solve the problem of high test complexity in the test of the touch electrode layer in the prior art, an embodiment of the present invention provides a panel and a test method thereof.

[0042] The main idea of the embodiment of the present invention is to build a test environment on the panel (without cutting) with the touch electrode layer, and then conduct a test based on the test environment, and then cut it after the test to obtain a single display panel. In this test environment, the smaller drive signal input pin on the display panel is connected to the first test pad outside the display panel through the first test line, and the smaller inter-channel capacitance output pin on the display panel is connected to the display panel. The second test pad outside the panel is connected through the second test line, and the above connection needs to ensure that when the touch electrode layer is tested, for any channel pair, when connected to the first channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com