Discrete vacuum-pumping transformer oil transfer system

A transformer oil transfer system technology, applied in the direction of transformer/inductor cooling, switchgear, electrical components, etc., can solve the problem of secondary pollution of transformer oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

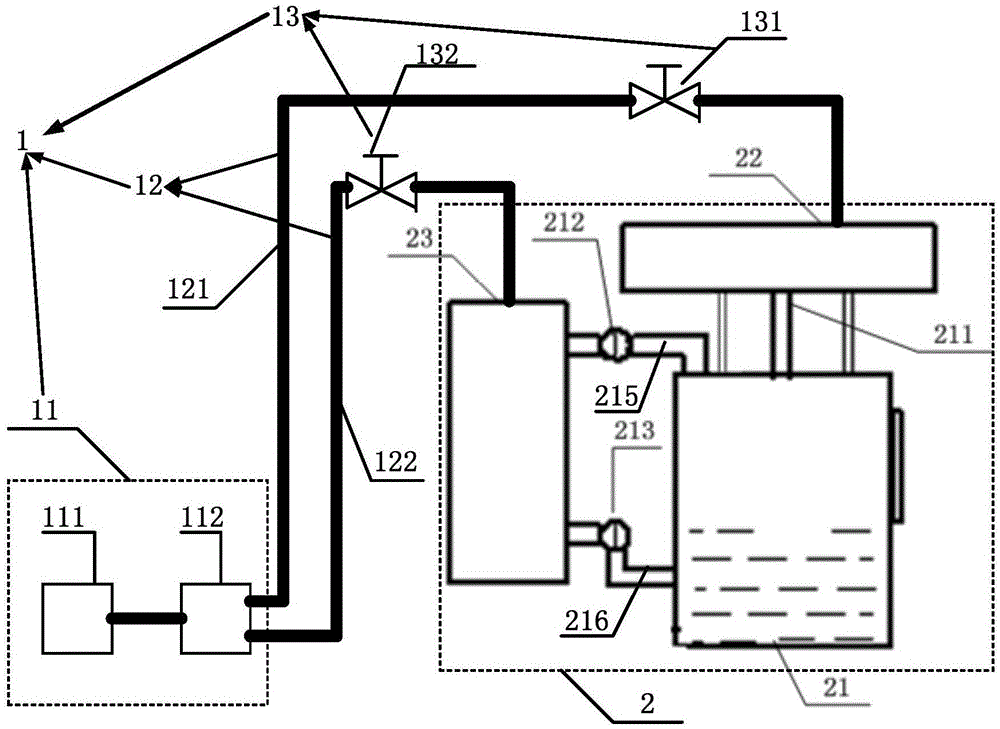

[0038] This embodiment provides a discrete vacuum transformer oil transfer system, such as image 3 As shown, a vacuum module 1 and a transformer 2 are included.

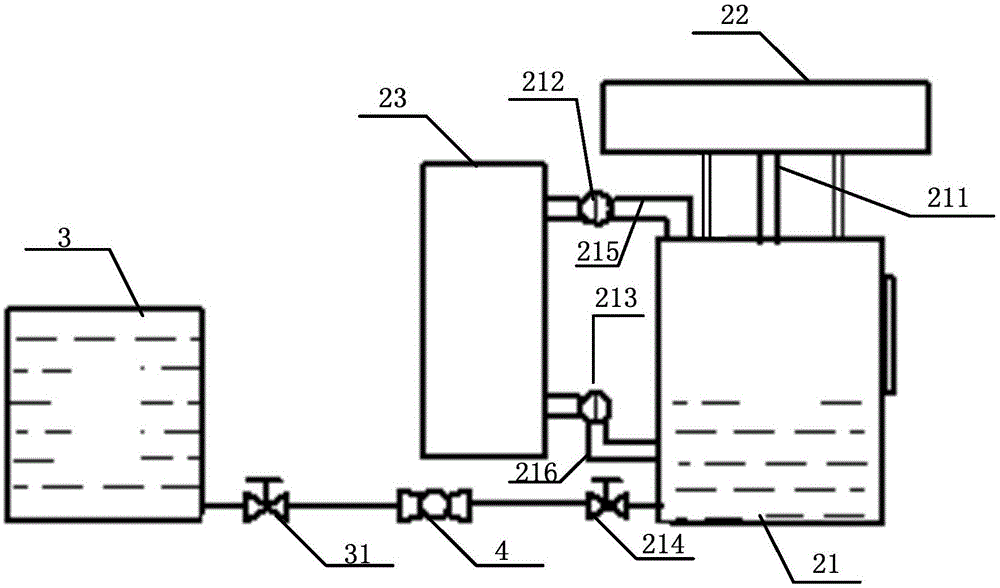

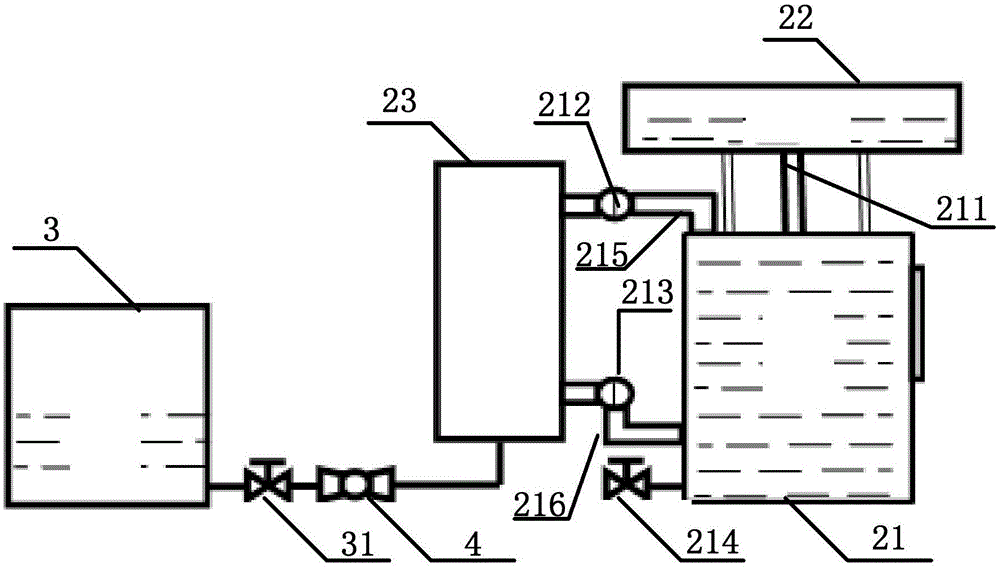

[0039] The transformer 2 includes a box body 21, an oil conservator 22 and a radiator 23. The box body 21 communicates with the oil conservator 22 through a first oil pipe 211; the box body 21 is connected through a second oil pipe 215 and a third oil pipe 215. The oil pipe 216 communicates with the radiator 23, the second oil pipe 215 is provided with a first butterfly valve 212, and the third oil pipe 216 is provided with a second butterfly valve 213, passing through the first butterfly valve 212 and the second The opening and closing of the butterfly valve 213 controls whether the tank 21 communicates with the radiator 23 .

[0040] The vacuum module 1 includes a vacuum device 11 , a connecting pipe 12 and a control valve 13 .

[0041] The connecting pipe 12 includes a first connecting pipe 121 , one end of whi...

Embodiment 2

[0053] On the basis of Embodiment 1, the discrete vacuum transformer oil transfer system described in this embodiment, such as Figure 4 As shown, as another optional implementation manner, the vacuuming module 1 further includes a radiator vacuuming device 11a, a radiator connecting pipe 12a, and a radiator control valve 13a.

[0054] One end of the radiator connecting pipe 12 a is in sealing communication with the radiator vacuum device 11 a , and the other end is in sealing communication with the radiator 23 .

[0055] The radiator control valve 13 a is arranged on the radiator connecting pipe 12 a for controlling whether the radiator vacuum device 11 a communicates with the radiator 23 or not.

[0056] As a preferred embodiment, in the discrete vacuum pumping transformer oil transfer system described in this embodiment, the radiator vacuum pumping device 11a includes a second vacuum pump 111a and a second separation tank 112a communicated with each other; One end of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com