igbt protection circuit and protection method in stepper motor driver

A technology for stepping motors and protection circuits, applied to emergency protection circuit devices, electrical components, etc., can solve the problems of low IGBT judgment accuracy, short circuit overcurrent fault tolerance time, and short service life of IGBT, so as to reduce the number of protection times, The effect of improving life and stability and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

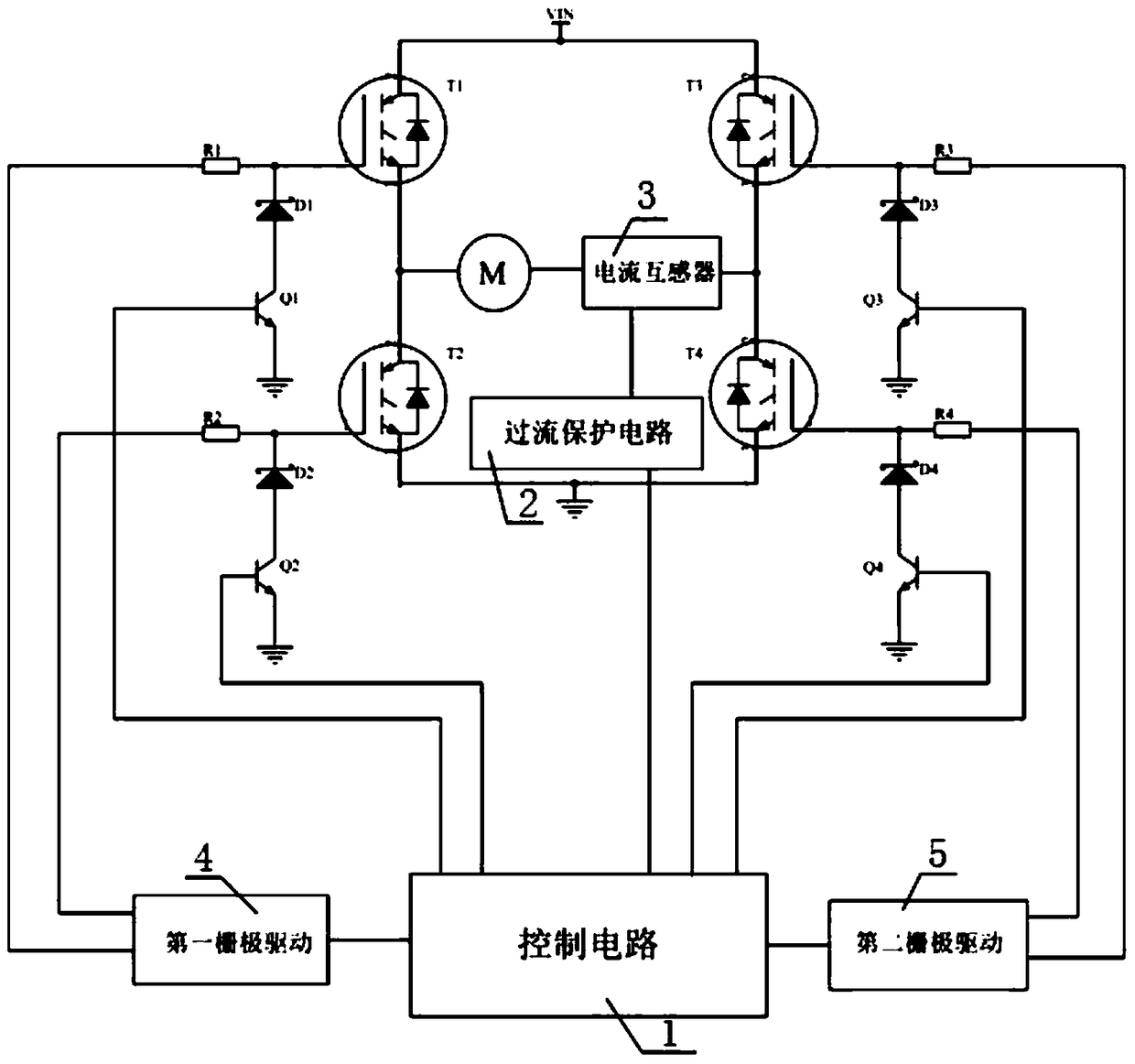

[0020] Specific implementation scheme 1, this scheme is specifically designed to protect the first type of overcurrent. Such as Figure 1 As shown, this scheme mainly includes control circuit 1, overcurrent protection circuit 2, current transformer 3, first gate driver 4, second gate driver 5, IGBTT1~T4, gate resistors R1~R4, gate stabilizer Diodes D1-D4 and transistors Q1-Q4. The control circuit 1 is connected to the first gate drive, the second gate drive and the bases of the transistors Q1~Q4, and the first gate drive and the second gate drive are connected to the IGBTs T1~T4 through the gate resistors R1~R4 The grid is connected, the collectors of the transistors Q1~Q4 are connected to the cathodes of the Zener diodes D1~D4, the anodes of the Zener diodes D1~D4 are connected to the gates of the IGBT T1~T4, and the IGBT T1~T4 and the stepping motor coil form an H-shaped PWM power In the conversion circuit, the current transformer 3 is connected in series in the motor coil...

specific Embodiment approach 2

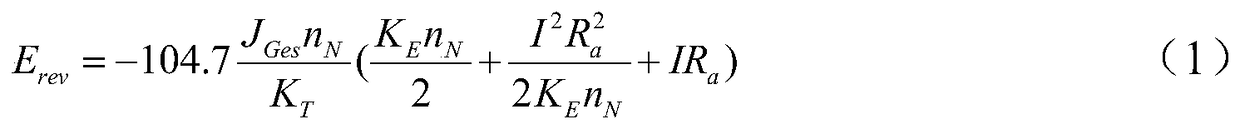

[0031] Specific embodiment 2. This embodiment is a specific example of protecting the second type of overcurrent: when the stepper motor is working, because the coil is an inductive element, it will store a certain amount of feedback energy. When the stepper motor brakes or When reversing, the feedback energy can be calculated as follows:

[0032]

[0033] where J Ges is the total inertia of the stepping motor, n N is the motor speed, K T is the motor torque coefficient, K E Is the back electromotive force coefficient of the motor, I is the braking current, R a is the internal resistance of the stepping motor coil, when the stepping motor rotates, R a Can be expressed as:

[0034] R a =ωL+r=9.549n N L+r (2)

[0035] Where ω is the angular velocity of the stepping motor, ω=9.549n N , L is the inductance of the stepping motor coil, r is the static internal resistance of the motor coil;

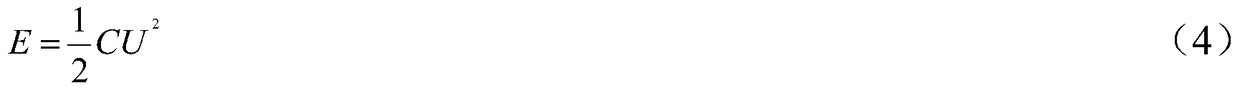

[0036]Let the highest voltage of the power supply be U s·max ,but:

[0037] u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com