Brake chopper power unit

A brake chopper and power unit technology, applied in the direction of output power conversion device, DC power input conversion to DC power output, electrical components, etc., can solve the inconvenient parts replacement, storage, large space occupation, and power circuit structure Complexity and other issues, to reduce design and operation maintenance costs, improve operational stability and life, and shorten the design cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further explained below in conjunction with the drawings:

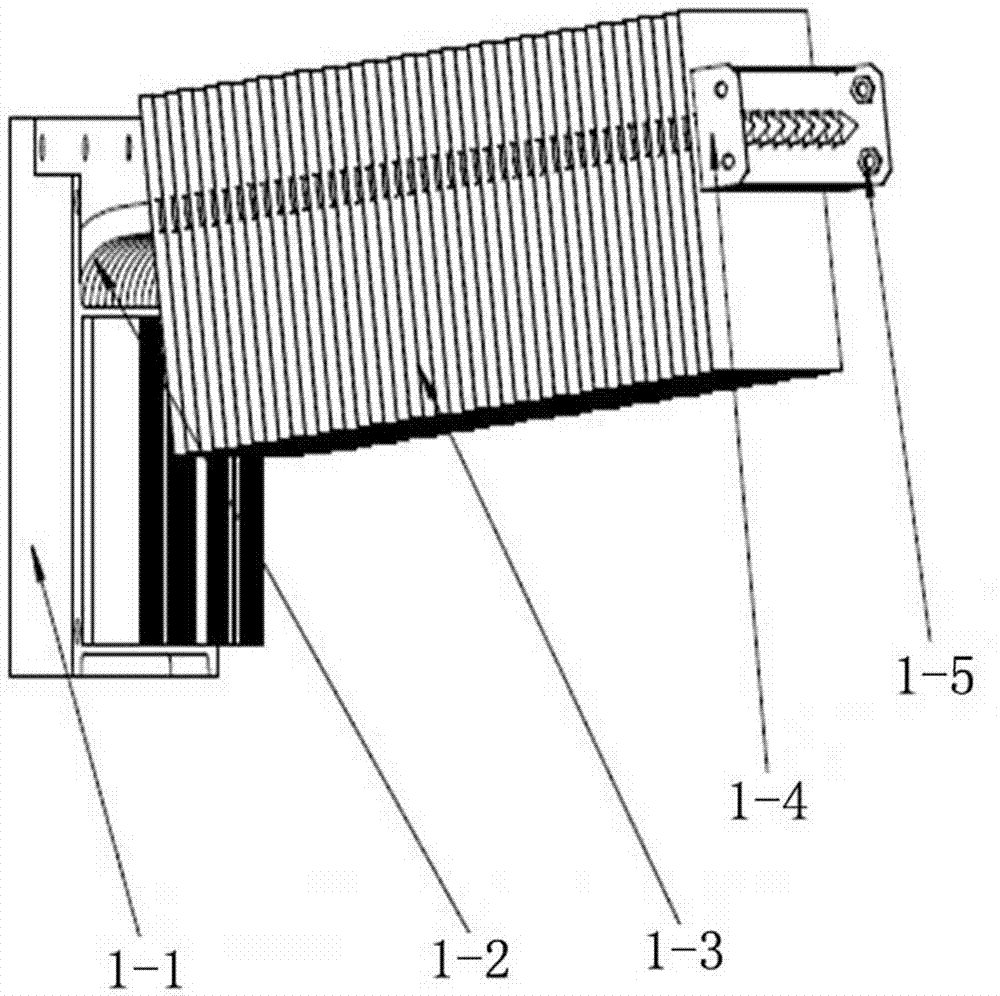

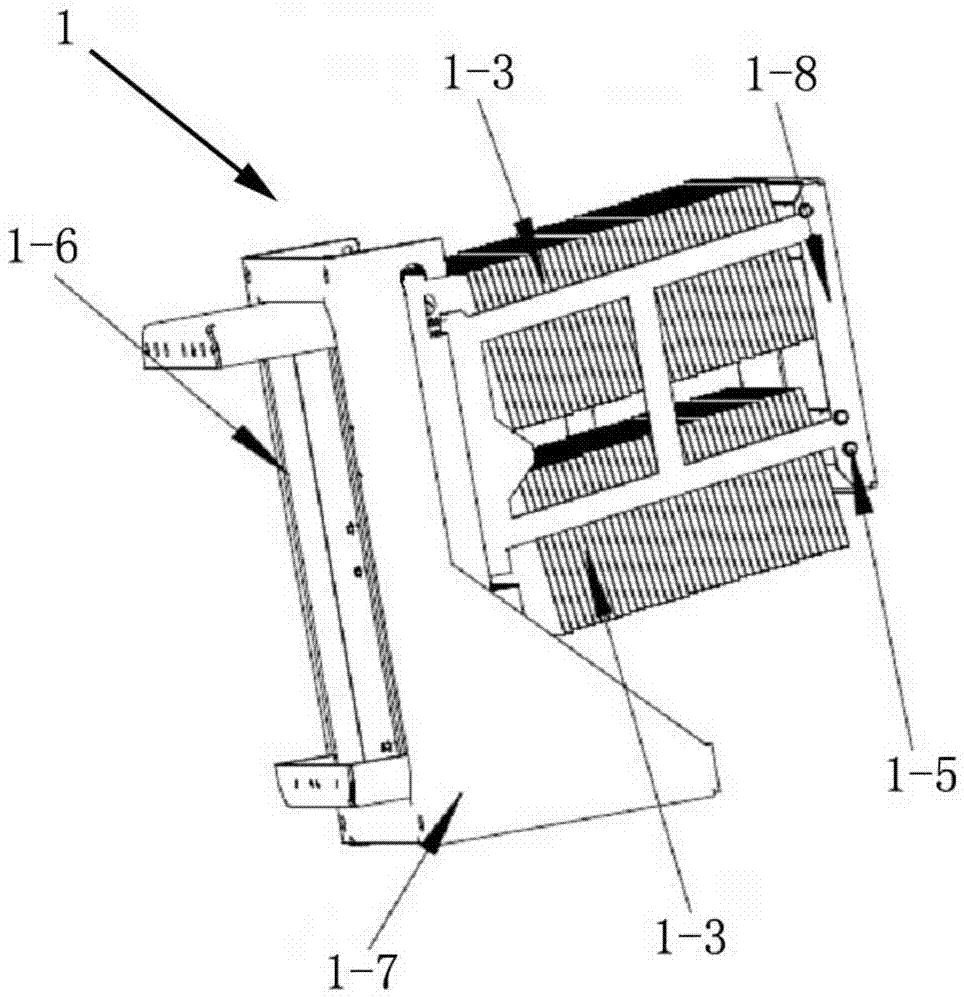

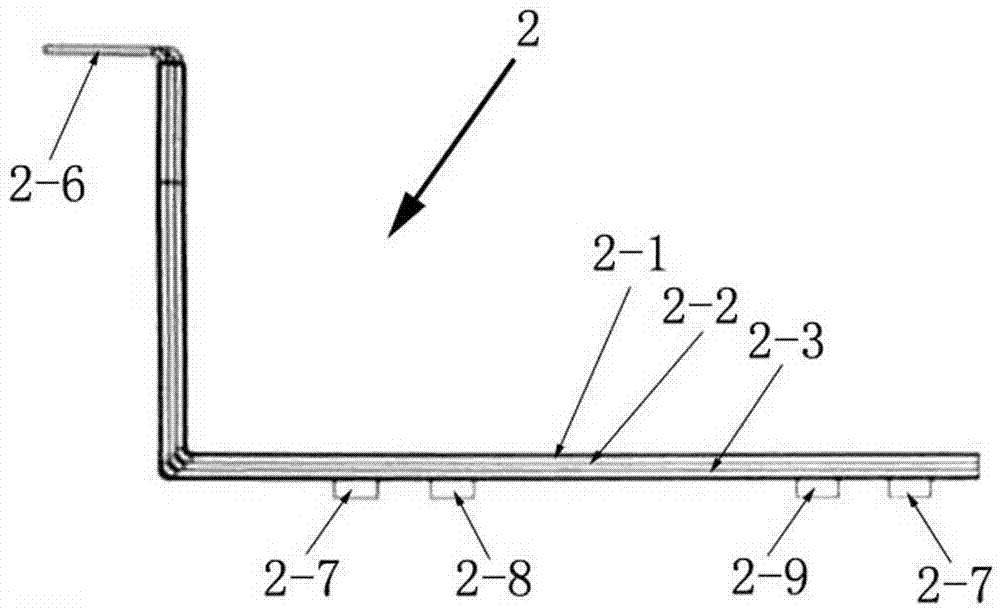

[0048] Such as Figure 1 to Figure 7 As shown, a new type of braking chopper power unit includes a radiator 1 and a composite busbar 2; the radiator 1 includes two upper and lower sections of heat pipe radiator units, and each section of the heat pipe radiator unit includes a heat dissipation substrate 1- 1. Several L-shaped heat pipes 1-2 and several fins 1-3, among which, the vertical pipes of several L-shaped heat pipes 1-2 are arranged in parallel with the heat dissipation substrate 1-1 and are directly embedded and fixed side by side on the heat dissipation substrate 1 -1, a number of radiating fins 1-3 are inserted and fixed one by one adjacent to the horizontal tubes of several L-shaped heat pipes 1-2, and the ends of the horizontal tubes of several L-shaped heat pipes 1-2 are installed and fixed together Mounting board 1-4, the two sides of the mounting board 1-4 are crimped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com