Work-vehicle engine device

A technology for working vehicles and engines, which is applied to power devices, engine components, combustion engines, etc., and can solve problems such as incomplete chemical reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

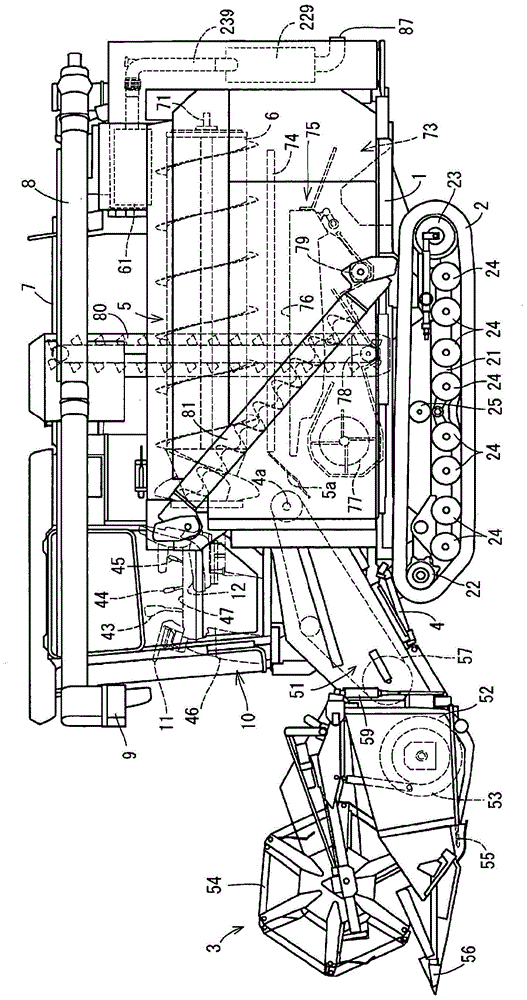

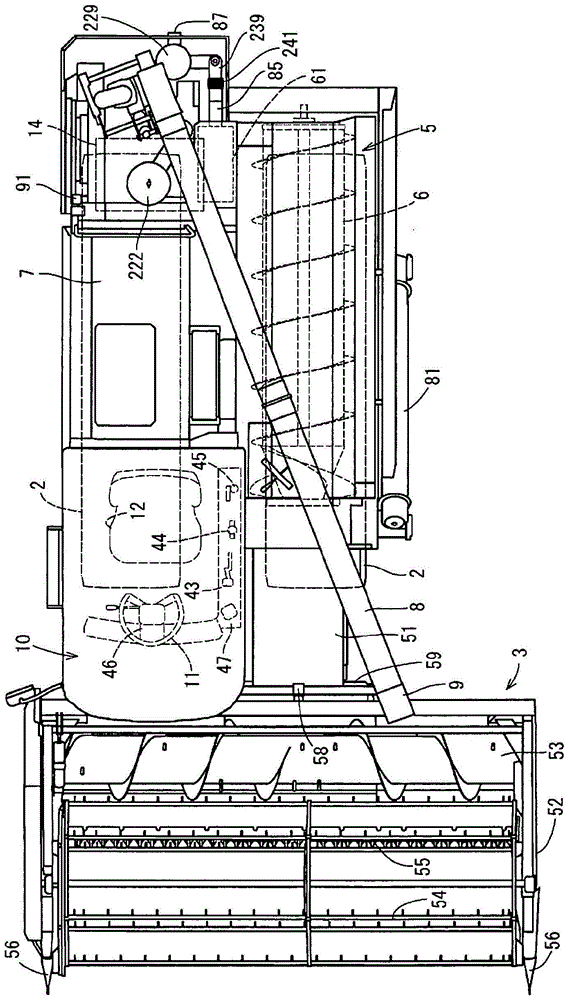

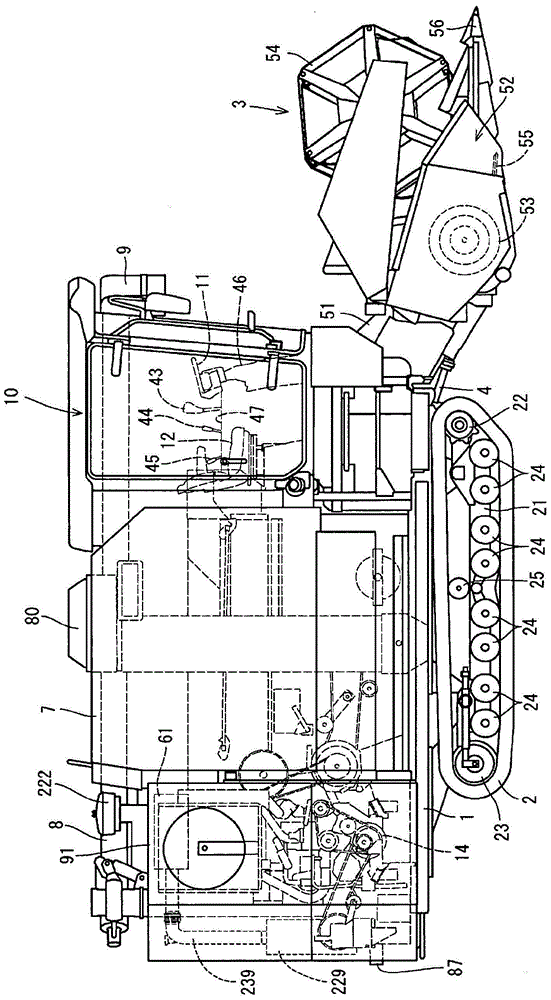

[0040] Hereinafter, embodiments for actualizing the present invention will be described with reference to the drawings. refer to Figure 1 ~ Figure 3 , illustrating the overall structure of the general-purpose combine harvester. In addition, in the following description, the left side toward the advancing direction of the traveling body 1 is simply called the left side, and the right side toward the advancing direction is also simply called the right side. Such as Figure 1 ~ Figure 3 As shown, a traveling body 1 supported by a pair of left and right walking crawler belts 2 as a running part is provided. At the front part of the traveling body 1, the harvesting device 3 for harvesting and introducing grain stalks is attached so as to be able to be raised and lowered around the harvesting rotation fulcrum shaft 4a by a single-acting hydraulic cylinder 4 for lifting. On the traveling body 1, the threshing apparatus 5 which has the threshing drum 6, and the grain tank 7 which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com