Manufacturing method of glass substrate for magnetic disk, manufacturing method of magnetic disk, and polishing pad

A technology of glass substrates and manufacturing methods, which is applied in the direction of grinding machine tools, manufacturing tools, grinding tools, etc., can solve the problems of narrow intervals and increased proportion of glass substrates, and achieve the effect of reducing micro-scar defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0057] A glass substrate for a magnetic disk usually undergoes a rough grinding process (rough grinding process), a shape processing process, a finish grinding process (finish grinding process), an end surface grinding process, and a main surface grinding process (first grinding process, second grinding process, etc.) ), chemical strengthening process, etc. to manufacture.

[0058] In the manufacture of this glass substrate for magnetic disks, first, molten glass is molded into a disk-shaped glass substrate (glass disk) by direct press. In addition, in addition to using such a direct press method, it is also possible to cut the sheet glass produced by the down-draw method or the float method into predetermined sizes, and obtain a glass substrate. Next, the main surface of the molded glass substrate is ground (polished) to improve dimensional accuracy and shape accuracy. In this grinding step, the main surface of the glass substrate is generally ground with hard abrasive grain...

no. 2 approach

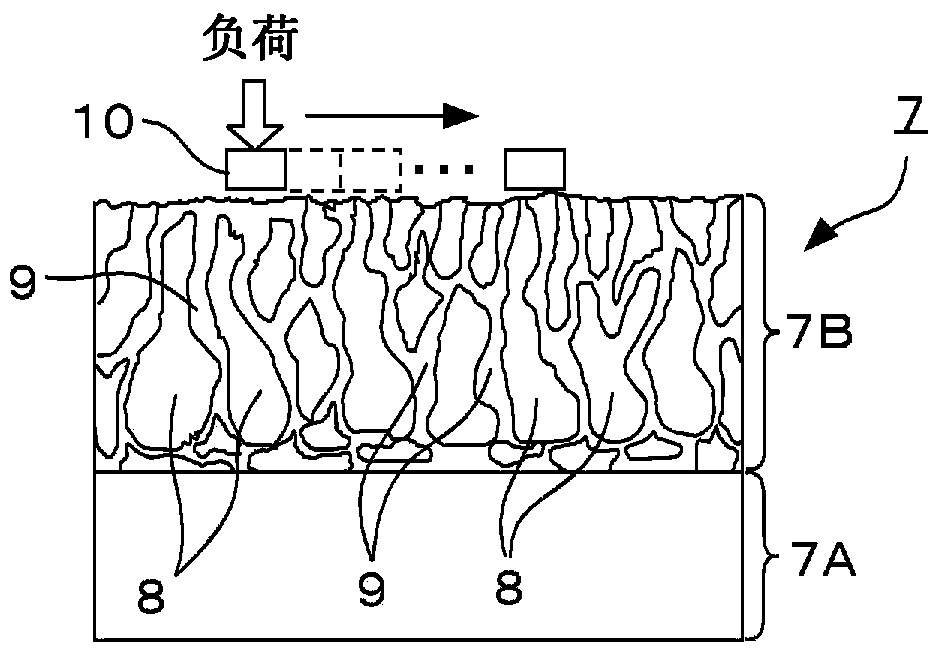

[0092] As shown in the above configuration 3, the second embodiment of the present invention is a method of manufacturing a glass substrate for a magnetic disk, the method of manufacturing a glass substrate for a magnetic disk including the following grinding treatment: Supply the polishing liquid that comprises abrasive grain, press-bond the polishing pad that is provided with foamed resin layer simultaneously, the glass substrate surface is ground, as above-mentioned polishing pad, use following polishing pad: from the surface as polishing surface of above-mentioned polishing pad to When a load of 2.5 mN is pressed into the circular portion of a cylindrical indenter with a diameter of 50 μm, the amount of sinking of the above-mentioned polishing pad is measured, and the sinking amount of 12 points is continuously obtained at intervals of 50 μm on the surface of the above-mentioned polishing pad. Among the acquired sinking amounts, when an arithmetic mean is obtained from the ...

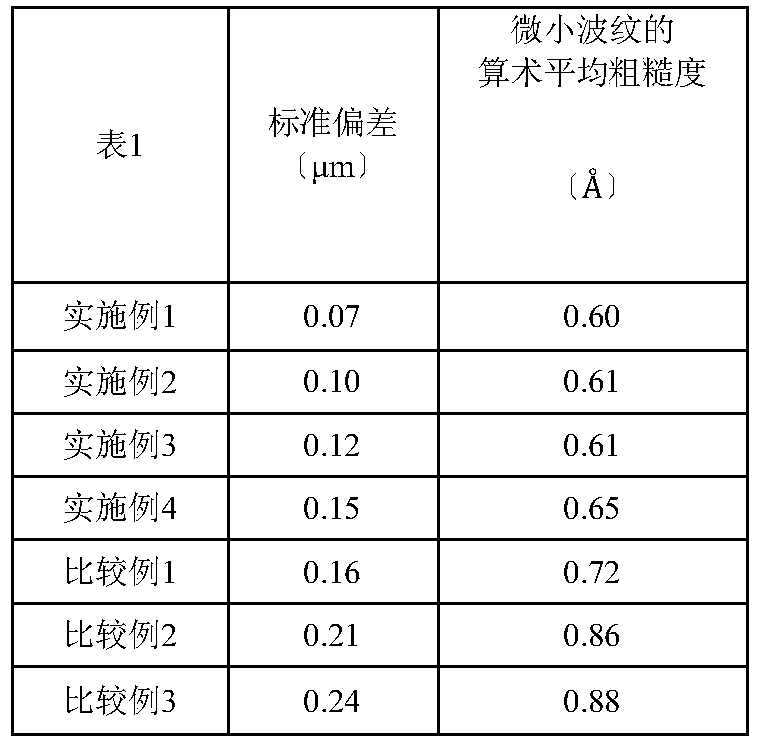

Embodiment 1~4、 comparative example 1~3

[0129] After the following (1) rough grinding process (rough grinding process), (2) shape processing process, (3) finish grinding process (finish grinding process), (4) end surface grinding process, (5) main surface A glass substrate for a magnetic disk is produced in a polishing step (first polishing step), (6) a chemical strengthening step, and (7) a main surface polishing step (second polishing step).

[0130] (1) Rough polishing process

[0131] First, a diameter of A disk-shaped glass substrate made of aluminosilicate glass with a thickness of 1.0 mm. Moreover, in addition to obtaining a glass substrate by such direct press, it is also possible to obtain a glass substrate by cutting sheet glass produced by a down-draw method or a float method into a predetermined size.

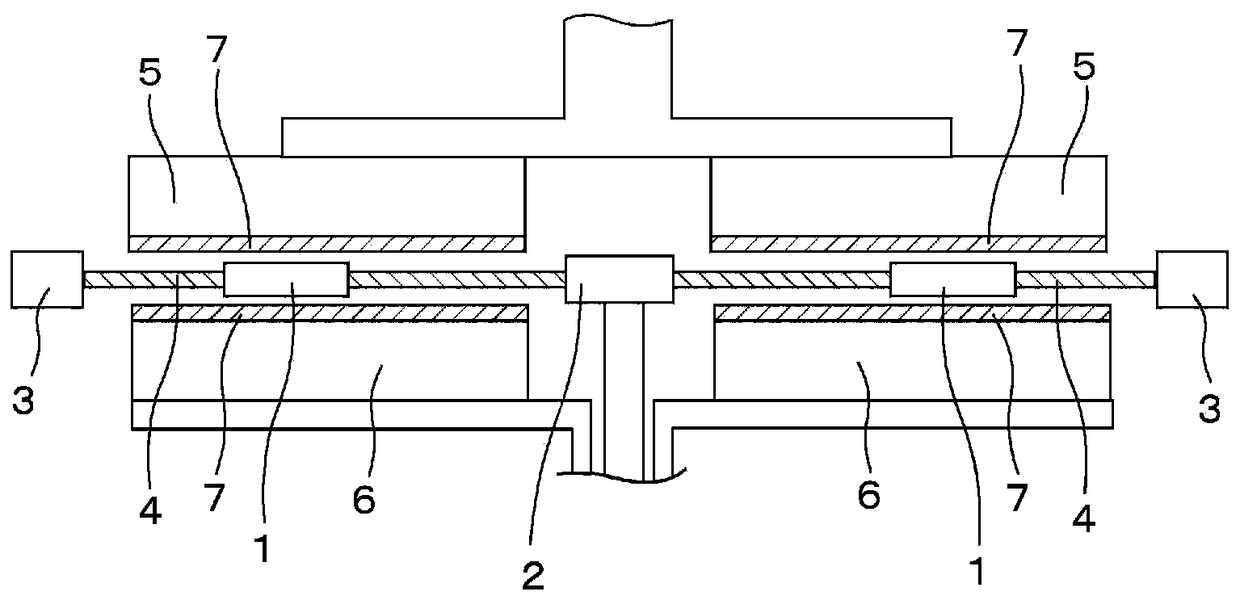

[0132]Next, the glass substrate is subjected to a polishing process to improve dimensional accuracy and shape accuracy. This polishing step is performed using a double-side polishing device.

[0133]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com