Structure and method for constructing sport field turf by using construction waste

A sports field and lawn technology, which is applied in the field of sports field lawn construction, can solve the problems of special construction equipment required by the spraying method, difficulty in uniform mixing of planting layers, and uneven growth of lawns, so as to achieve reasonable thickness setting of each layer and realize reduction and resources, increase the effect of urban green area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

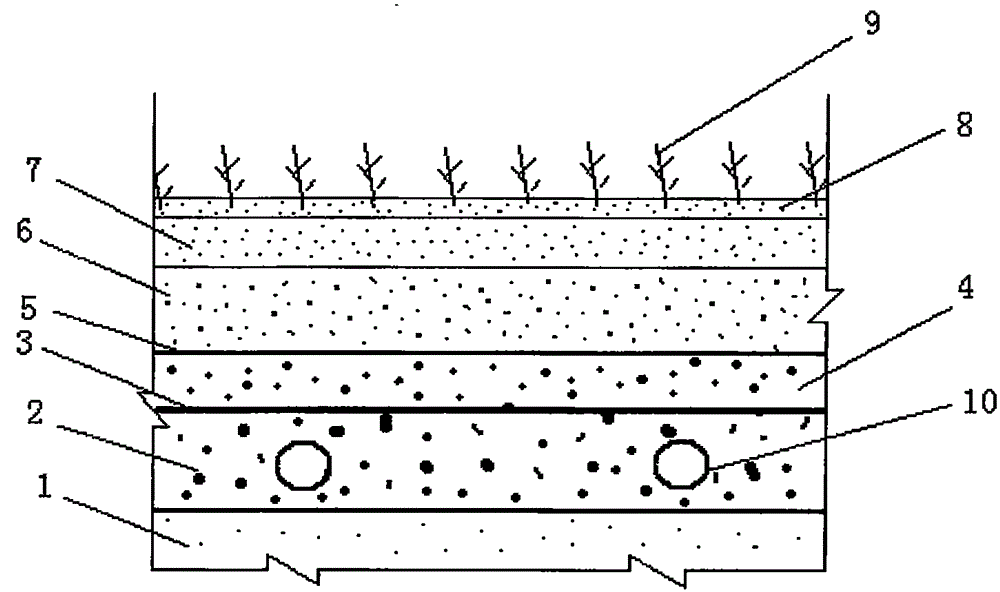

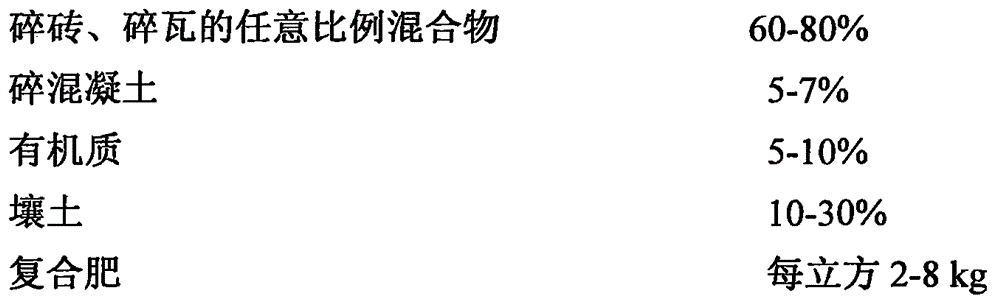

[0078] The structure of each layer of lawn in a football field in the south is as follows: on the foundation of the field, there is a drainage layer with a thickness of 30cm composed of large particles of construction waste with a particle size of 10-50mm, and a drainage blind pipe with an inner diameter of 10cm is embedded at the bottom of the drainage layer; The layer is covered with a plastic net with a pore size of 0.9 mm; the plastic net is a filter layer with a thickness of 20 cm composed of coarse particle construction waste with a particle size of 1-6 mm, and a layer of non-woven fabric is covered on it; The bottom layer with a thickness of 20cm is composed of construction waste as the main material, on which is a middle layer with a thickness of 9cm and a surface layer with a thickness of 0.8cm; the surface layer has a vegetation layer.

[0079] Drainage blind pipes are made of plastic blind pipes, arranged every 3m, and connected with the drainage ditch around the foo...

Embodiment 2

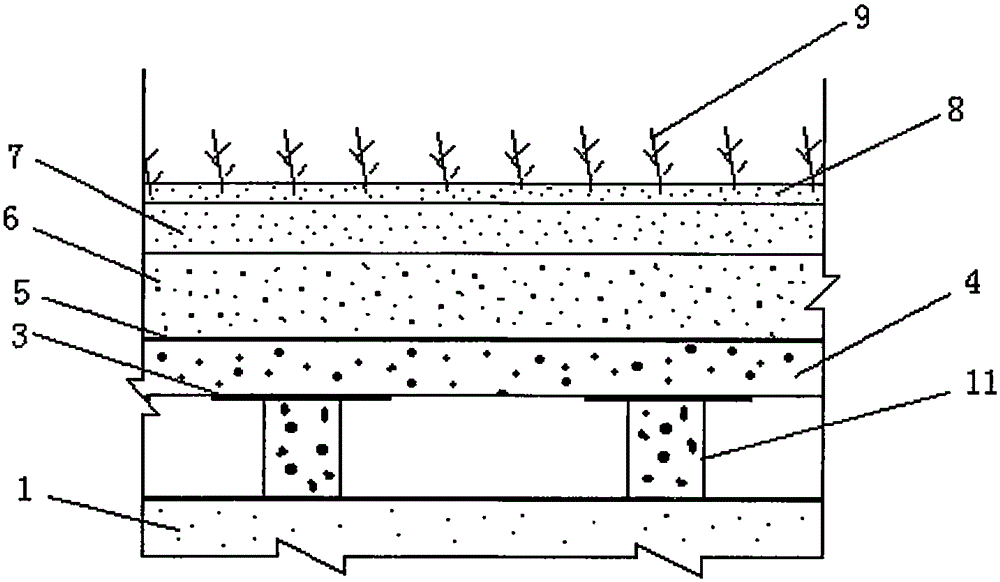

[0108] The structure of each layer of lawn in a football field in the north is as follows: on the basis of the field, a drainage blind ditch is arranged every 5m. The depth of the blind ditch is 20cm and the width is 30cm. The blind ditch is filled with large particles of construction waste with a particle size of 10-50mm; The blind ditch is covered with a layer of plastic net with a pore size of 0.9mm; the plastic net is a filter layer with a thickness of 15cm composed of coarse particle construction waste with a particle size of 1-6mm, and a layer of non-woven fabric is covered on it; The bottom layer with a thickness of 30cm is composed of construction waste as the main material, on which is a middle layer with a thickness of 15cm and a surface layer with a thickness of 1.2cm; the surface layer has a vegetation layer.

[0109] The non-woven fabric is a high-strength non-woven fabric made of polypropylene man-made fibers cross-laid and needle-punched.

[0110] Construction w...

Embodiment 3

[0137]The structure of each layer of the fairway lawn of a golf course in the middle and lower reaches of the Yangtze River is as follows: on the foundation of the field, a drainage blind ditch is arranged every 4m, the depth of the blind ditch is 30cm, and the width is 30cm. root, and fill the blind ditch with large particles of construction waste with a particle size of 10-50 mm; then cover the blind ditch with a layer of plastic net with a pore size of 0.9 mm; lay coarse construction waste with a particle size of 1-6 mm on the plastic net It consists of a filter layer with a thickness of 15cm, which is covered with a layer of non-woven fabric; the non-woven fabric is a bottom layer with a thickness of 25cm composed of construction waste as the main material, and a middle layer with a thickness of 12cm and a layer with a thickness of 1cm. Surface layer; there is a vegetation layer on the surface layer.

[0138] The non-woven fabric is a high-strength non-woven fabric made of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com