Food-grade pumpkin seed oil microemulsion and preparation method thereof

A technology of pumpkin seed oil and microemulsion, which is applied in the fields of edible oil/fat, food science, application, etc., can solve the problems such as the inability to obtain a uniform microemulsion system, and achieve the advantages of enhancing oxidation stability, solving low solubility and promoting stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

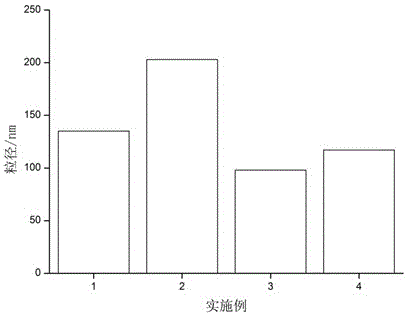

Embodiment 1

[0022] Embodiment 1, a kind of food-grade pumpkin seed oil microemulsion is made of six polyglycerol monolaurate and Span series surfactant mixture 23Kg, nanometer SiO 2 0.2Kg, pumpkin seed oil 10Kg, water 66.8Kg composition, wherein the mass ratio of hexapolyglycerol monolaurate and span series surfactant is 4:1, the preparation method of present embodiment pumpkin seed oil microemulsion is: Under the condition of continuous stirring, the stirring rate is 200rpm. First add the mixture of hexapolyglycerol monolaurate and Span series surfactant into the mixing kettle. The Span series surfactant is Span80, then add pumpkin seed oil, and finally add Dissolved with nano-SiO 2 The aqueous solution, to obtain a transparent, uniform system is the desired microemulsion system.

Embodiment 2

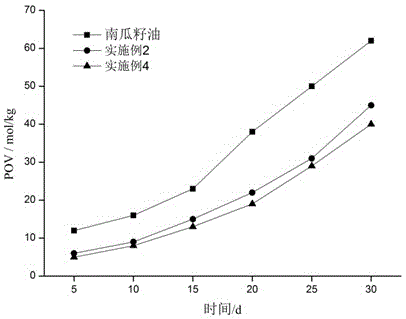

[0023] Embodiment 2, a kind of food-grade pumpkin seed oil microemulsion is made of six polyglycerol monolaurate and Span series surfactant mixture 30Kg, nanometer SiO 2 0.5Kg, pumpkin seed oil 30Kg, water 39.5Kg, wherein, the mass ratio of six polyglycerol monolaurate and span series surfactant is 5:1; The preparation method of present embodiment pumpkin seed oil microemulsion is: Under the condition of continuous stirring, the stirring speed is 300rpm. First add the mixture of hexapolyglycerol monolaurate and Span series surfactants into the mixing tank. The Span series surfactants are the mixture of Span80 and Span60 in any proportion, and then add Pumpkin seed oil, finally added with nano-SiO 2 The aqueous solution, to obtain a translucent, uniform system is the desired microemulsion system. figure 2 The data showed that the oxidation stability of pumpkin seed oil in the microemulsion was significantly improved.

Embodiment 3

[0024] Embodiment 3, a kind of food-grade pumpkin seed oil microemulsion is made of six polyglycerol monolaurate and Span series surfactant mixture 16Kg, nanometer SiO 2 0.1Kg, pumpkin seed oil 4Kg, water 79.9Kg, wherein the mass ratio of hexaglycerol monolaurate to Span series surfactants is 10:1. The preparation method of the pumpkin seed oil microemulsion in the present embodiment is: under the situation of continuous stirring, stirring speed is 400rpm, in mixing kettle, add hexaglycerol monolaurate and Span series surfactant mixture earlier, Pan series surfactants are a mixture of Span80, Span60, Span40, and Span20 in any proportion, then add pumpkin seed oil, and finally add nano-SiO 2 The aqueous solution, to obtain a transparent, uniform system is the desired microemulsion system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com