a ti 3+ Preparation of doped non-noble metal catalysts and their application in selective hydrogenation reactions

A non-precious metal, selective technology, applied in physical/chemical process catalysts, hydrogenation to hydrocarbons, bulk chemical production, etc., can solve the problems of high catalyst cost, short catalyst life, easy carbon deposition, etc., and achieve low cost and high cost. Conversion rate, high selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

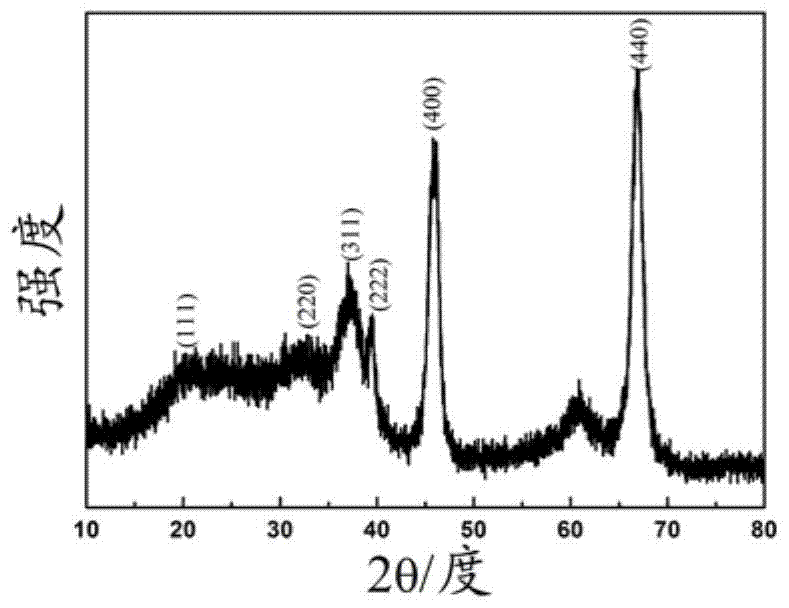

[0045] Weigh 1g γ-Al 2 o 3 The nanotubes were dried in an oven at 100° C. for 2 hours, and set aside. Measure 0.3 g of butyl titanate and dissolve in 30 mL of a mixed solution of ethanol and toluene (volume ratio 1:1). The dried γ-Al 2o 3 The nanotubes were slowly added into the mixed solution of ethanol and toluene, and stirred at 20°C for 20 hours. Then centrifuge, discard the supernatant, and take the lower layer of sediment. The centrifuged product was dried in an oven at 100° C. for 4 hours, and then ground into powder. Finally, the obtained powder was placed in a tube furnace, and the temperature was programmed to rise to 500°C at a rate of 5°C / min in an air atmosphere. After calcination for 2 hours, it was cooled to room temperature, and then switched to 5% H 2 / N 2 Gas was heated up to 500°C at a rate of 10°C / min, and calcined for 2 hours to obtain Ti 3+ Doped non-noble metal hydrogenation catalysts. The composition and internal structure of the product were c...

Embodiment 2

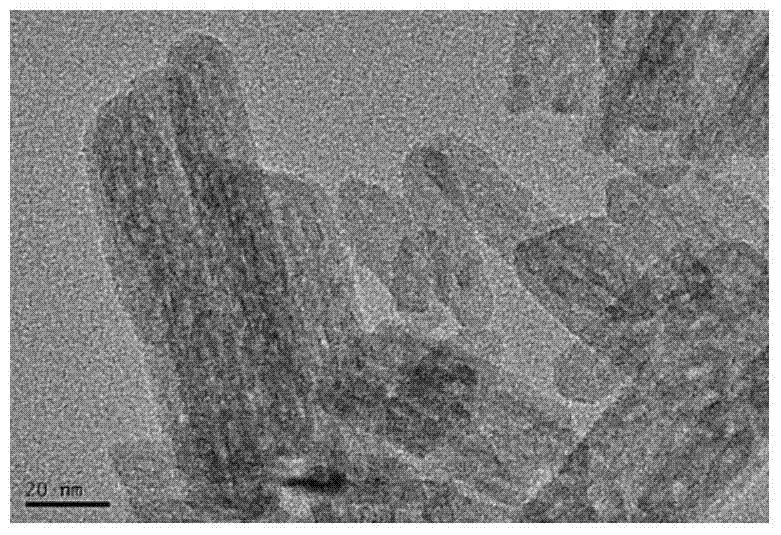

[0047] Weigh 2g γ-Al 2 o 3 The nanotubes were dried in an oven at 120° C. for 2 hours, and set aside. Measure 0.6 g of butyl titanate and dissolve in 30 mL of a mixed solution of ethanol and toluene (volume ratio 1:1). The dried γ-Al 2 o 3 The nanotubes were slowly added into the mixed solution of ethanol and toluene, and stirred at 20° C. for 25 hours. Then centrifuge, discard the supernatant, and take the lower layer of sediment. The centrifuged product was dried in an oven at 120° C. for 6 hours, and then ground into powder. Finally, the obtained powder was placed in a tube furnace, and the temperature was programmed to rise to 400°C at a rate of 5°C / min in an air atmosphere, and after calcination for 4 hours, it was cooled to room temperature, and then switched to 5% H 2 / N 2 Ti 3+ Doped non-noble metal hydrogenation catalysts. The morphology of the product was characterized by high-power transmission electron microscopy, such as image 3 shown.

Embodiment 3

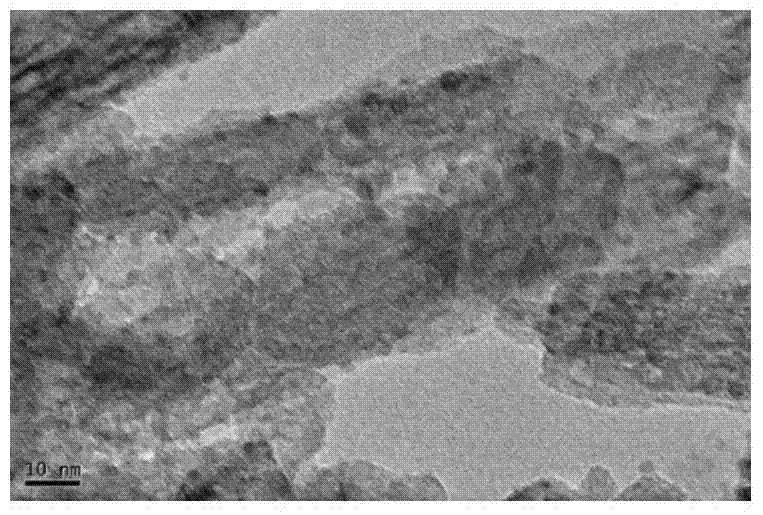

[0049] Weigh 1.6g γ-Al 2 o 3 The nanotubes were dried in an oven at 100°C for 3 hours, and set aside. Measure 0.55 g of butyl titanate and dissolve in 30 mL of a mixed solution of ethanol and toluene (volume ratio 1:1). The dried γ-Al 2 o 3 The nanotubes were slowly added into a mixed solution of ethanol and toluene, and stirred at 30° C. for 30 hours. Then centrifuge, discard the supernatant, and take the lower layer of sediment. The centrifuged product was dried in an oven at 100° C. for 4 hours, and then ground into powder. Finally, the obtained powder was placed in a tube furnace, and the temperature was programmed to rise to 400°C at a rate of 5°C / min in an air atmosphere. After calcination for 2 hours, it was cooled to room temperature, and then switched to 5% H 2 / N 2 Ti 3+ Doped non-noble metal hydrogenation catalysts. The morphology of the product was characterized by high-power transmission electron microscopy, such as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com