Cleaning device for substation secondary equipment

A secondary equipment and cleaning device technology, applied in cleaning methods and tools, cleaning methods using tools, cleaning methods using gas flow, etc., can solve problems such as dust falling back, damage to the health of cleaning personnel, and delays in construction schedules. Effects of excessive restriction, elimination of dust falling back phenomenon, and avoidance of damage to health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to facilitate the understanding of the technical content of the present invention, the technical solutions thereof will be further described below in conjunction with the accompanying drawings.

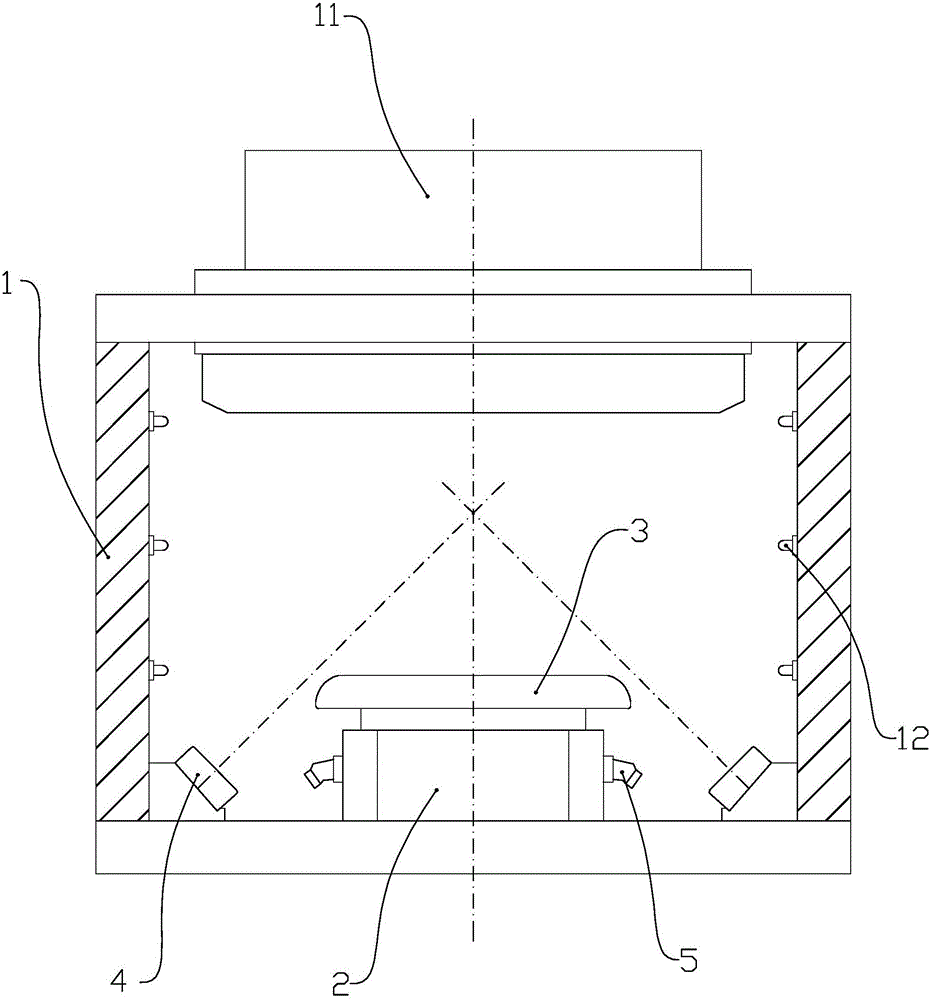

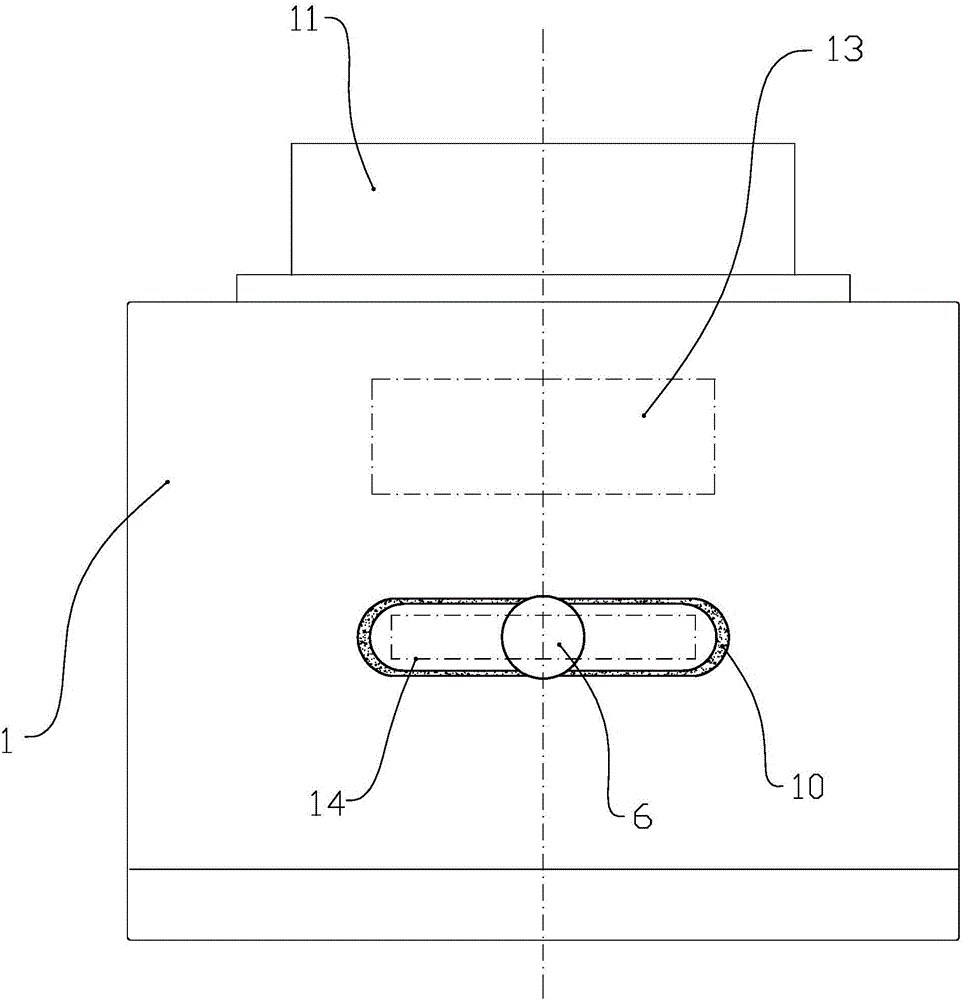

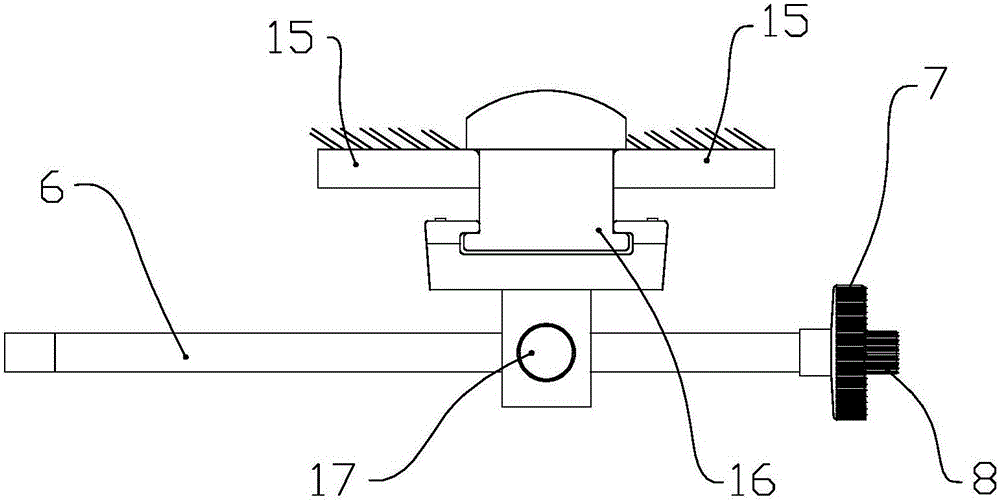

[0022] Such as Figure 1 to Figure 8 A substation secondary equipment cleaning device as shown:

[0023] It includes a sealed chamber 1, a rotary workbench 3, six main blowers 4, six auxiliary blowers 5, an operating rod 6 and a brush installed at the end of the operating rod 6.

[0024] Such as figure 1 As shown, the rotary workbench 3 is arranged on the workbench support 2 at the front side of the bottom of the sealed chamber 1 . The rotary table 3 is driven to rotate by a stepping motor. The stepper motor is fixed on the workbench support 2, connected with the control unit, and drives the rotary workbench 3 to rotate at a certain angle intermittently according to the cleaning process. The six main blowers 4 are distributed and arranged at the left and right corn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com