Automatic deviation correction method and system for solar panel cleaning vehicle in progress

A solar panel, automatic deviation correction technology, applied in the directions of cleaning methods and utensils, chemical instruments and methods, cleaning flexible objects, etc., can solve problems such as inability to use the chassis to correct deviation, and achieve the elimination of road bumps, array board surface undulations, elimination of The effect of measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution proposed by the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but it is not intended to limit the present invention.

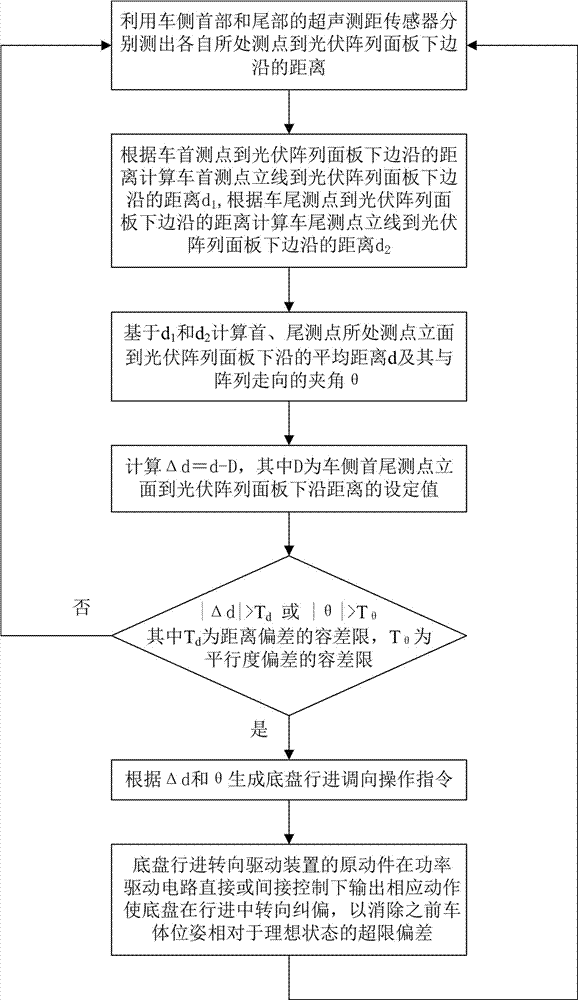

[0039] A kind of automatic deviation correction method in the progress of the solar panel cleaning vehicle of this embodiment, such as figure 1 shown, including the following steps:

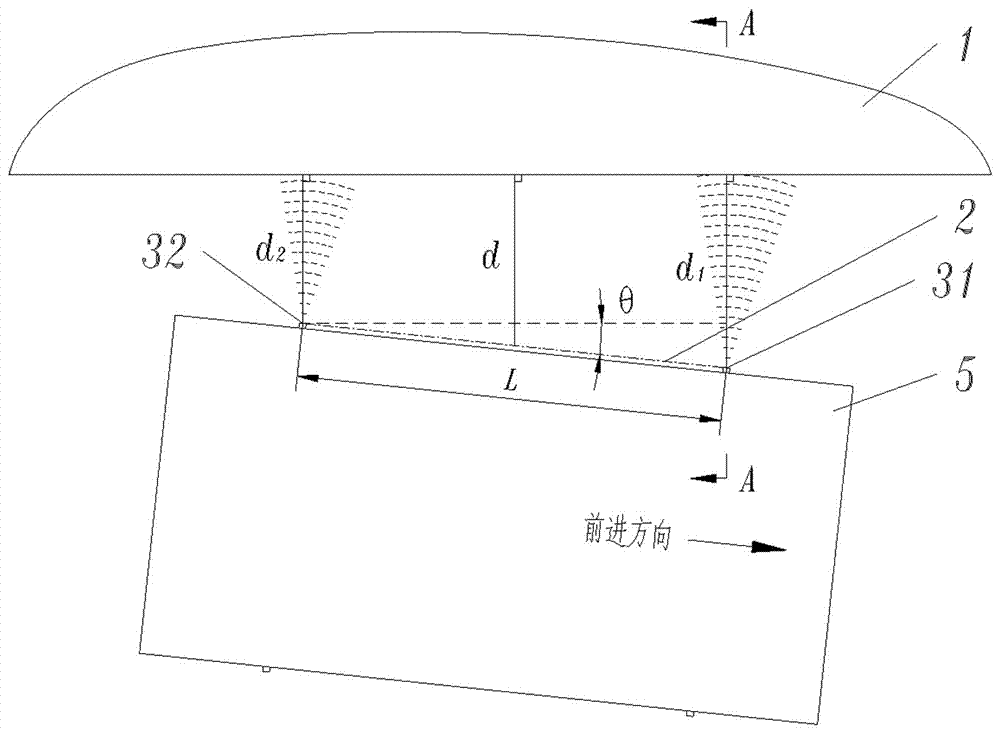

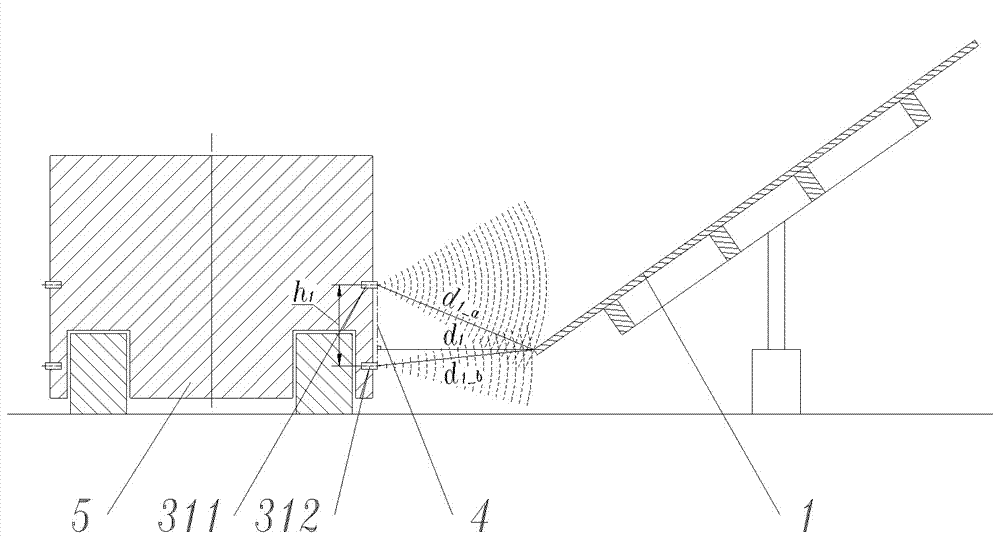

[0040] Step 1: Utilize the sensors in the vehicle-side head ultrasonic ranging sensor group 31 and the vehicle-side tail ultrasonic ranging sensor group 32 respectively installed on the head and tail of the car body 5 to measure the respective measuring points to the photovoltaic Distance from the bottom edge of the array panel. Both the front ultrasonic distance measuring sensor group 31 on the vehicle side and the ultrasonic distance measuring sensor group 32 on the vehicle side rear are composed of two ultrasonic distance measuring sensors arranged at intervals in a vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com