Turning, drilling and milling combined machine tool for machining flange

A compound machine tool, drilling and milling technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of limited popularity, high price, technical problems of core components, etc., and achieve stable performance, complete functions, and reliability high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

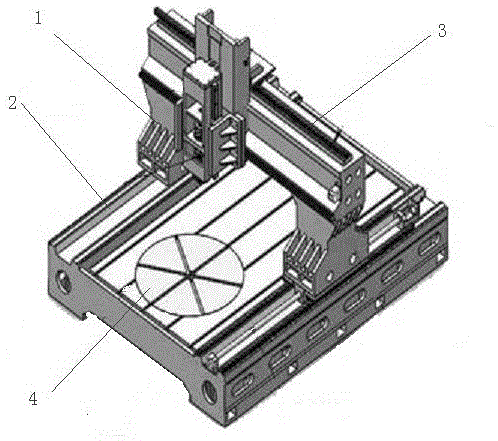

[0020] Specific implementation methods: such as figure 1 As shown, a turn-drilling-milling compound machine tool for processing flanges, including a bed of the machine tool, a workbench and a workbench base are arranged on the bed, columns and beams are arranged above the workbench, and a double-column type is arranged above the workbench. Symmetrical structure, the beam is a fixed beam type; guide rails are provided on both sides of the bed, and columns are provided on the guide rails to support the processing head; the bed is also equipped with a C-axis box, a tool holder, a servo feed system, Workbench clamping system, hydraulic system, button station; the machine tool has a vertical tool holder, which adopts a double ram structure, with the turning ram tool holder on the right and the milling ram tool holder on the left.

[0021] The main transmission mechanism and the C-axis box are arranged on the bed to form a turning and milling power assembly as a whole. The indexing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com