Regeneration cloth-manufacturing process for foamed EVA wasted materials

A waste material and fabric making technology, applied in the field of resource regeneration and polymer, can solve the problem of resource waste, and achieve the effect of saving raw materials and social resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

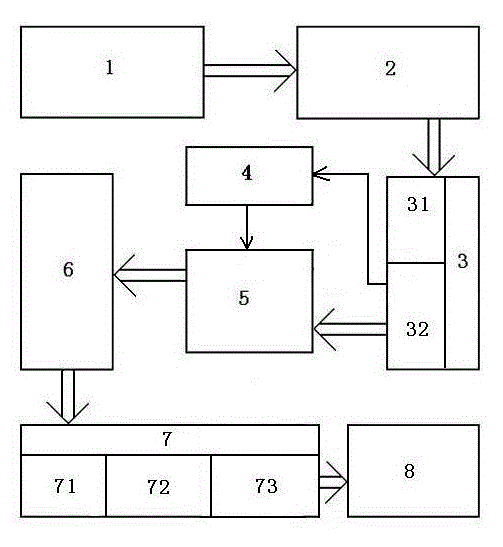

[0015] Embodiment 1: foamed EVA waste material regenerated cloth-making process comprises that foamed EVA waste material 1 is classified and sorted by product source and color sorting in the same source, the foamed EVA that will be sorted and sorted Waste 1 is crushed and mixed into well-dispersed foamed waste pellets. After the composition analysis and confirmation of the foamed waste pellets, the addition and compatibility of EVA raw materials, fillers and coloring materials are carried out according to specific purposes. 5 into the mixture 6, and then through internal mixer 71, open mill 72 mixed melting, calender cloth making machine 73 to make EVA regenerated material cloth 8 with special purpose.

Embodiment 2

[0016] Embodiment 2: The sources of foamed EVA waste materials include slippers, soles, etc., and the slippers and soles, including the defective products discarded in the manufacturing process, are distinguished, and then several commonly used colors are designed as sorting color areas, and then according to the color areas Color sorting is carried out, and individual colors outside the color zone are put into the black zone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com