Overhead Rigid Catenary Temperature Compensation Device

A temperature compensation device, rigid contact technology, applied in overhead lines, power rails, etc., can solve the problems of high installation accuracy, affecting driving safety, and heavy maintenance workload, ensuring the height difference of the contact line and avoiding the phenomenon of jamming , to ensure the effect of the quality of the flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

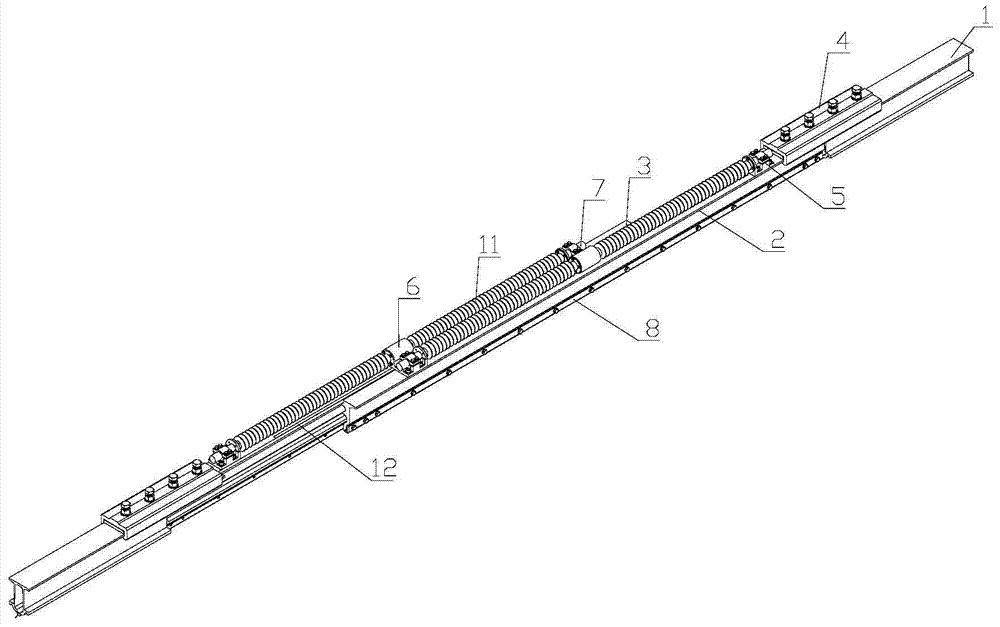

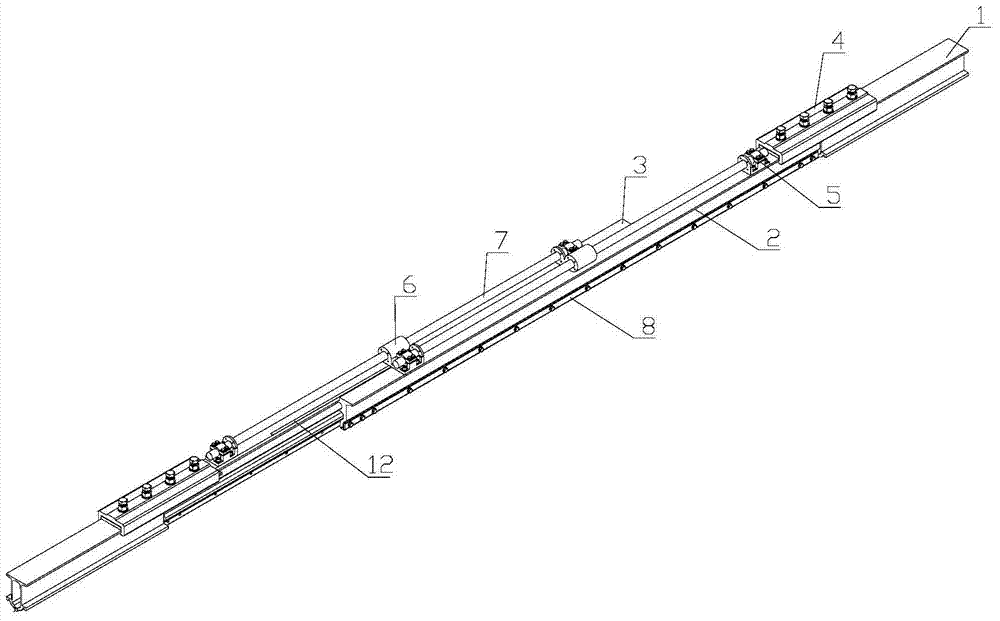

[0023] combined with Figure 1-7 Specific embodiments of the present invention will be described in detail.

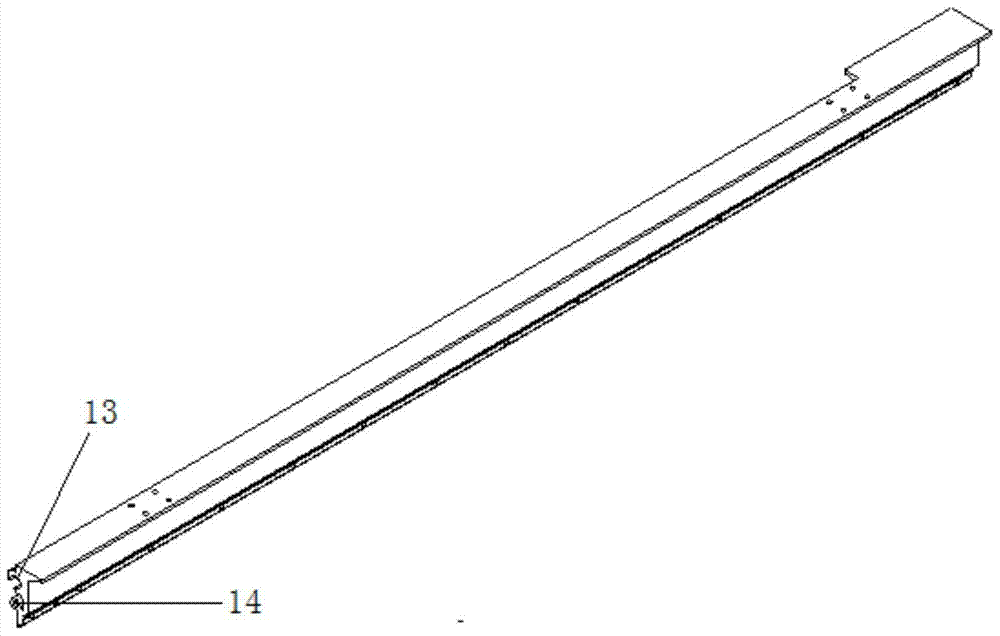

[0024] An overhead rigid catenary temperature compensation device, comprising a left sliding guide rail 2 and a right sliding guide rail 3, the outer ends of the left sliding guide rail 2 and the right sliding guide rail 3 are respectively connected and fixed to the bus bars 1 at both ends through the bus bar outsourcing joint 4, And the top cross section of the outer end of the left sliding guide rail 2 and the right sliding guide rail 3 is the same as the top cross section of the bus bar 1, so as to ensure the reliability of the connection with the bus bar. The inner sides of the left sliding guide rail 2 and the right sliding guide rail 3 are all formed with slideways 13 and slide rails 14, and the two slideways 13 and the two slide rails 14 are staggered up and down, and the slide rails 14 are inserted in the opposite sides. In the side slideway 13, the left slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com