Multi-rotor unmanned pesticide application machine

A multi-rotor unmanned, sprayer technology, applied in the field of plant protection aircraft, can solve the problems of bulky spraying system, complex nozzle structure, huge structure of the whole machine, etc., and achieve the effect of increasing the load capacity, lowering the strength requirements, and reducing the complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further elaborated below in conjunction with the accompanying drawings.

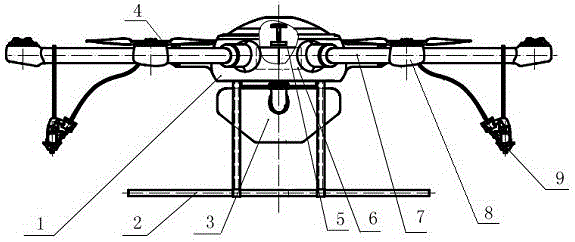

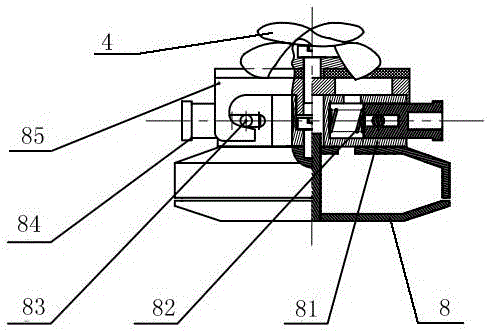

[0022] Such as figure 1 As shown, the present invention provides a multi-rotor unmanned spraying machine, which includes a body combination 1 and a medicine box combination 3 installed on the landing gear combination 2, and a flight control system 5 and a battery combination 6 are also provided inside the body combination 1. Some machine arm assemblies 7 are also installed on the body assembly 1, and the ends of the machine arm assemblies 7 are all provided with motors 92 and propellers 4, wherein two coaxial machine arm assemblies 7 are also equipped with nozzle assemblies 9 respectively.

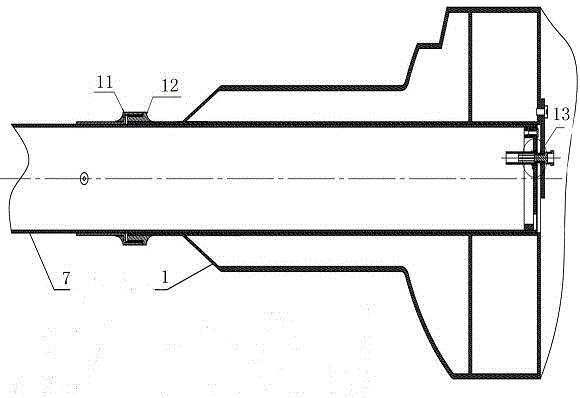

[0023] Such as figure 2 As shown, the machine arm assembly 7 is movably connected with the socket provided on the body assembly 1, and the connection joint between the outside of the socket and the machine arm assembly 7 is provided with a fastening thread 12 and a nut 11 struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com