Aluminium foil sealing film and preparation method thereof

A sealing film and aluminum foil technology, applied in chemical instruments and methods, sealing, closing, etc., can solve problems such as unraveling effort, uneven bonding strength, and sealing failure, and achieve easy peeling, improved quality, and moderate bonding strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

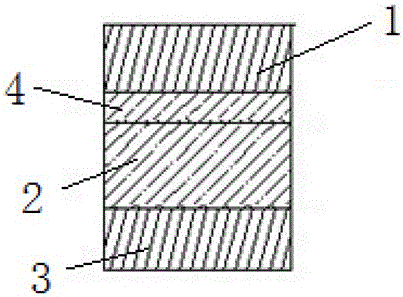

[0039] This embodiment provides an aluminum foil sealing film, such as figure 1 As shown, it includes a protective layer 1, a barrier layer 2 and a heat-sealing layer 3 that are laminated sequentially from top to bottom. Among them, the protective layer 1 is a varnish layer, the barrier layer 2 is an aluminum foil layer, and the heat-sealing layer 3 is composed of 15wt% polybutene, 25wt% metallocene LLDPE and 60wt% HDPE (high-density polyethylene).

[0040] The thickness of the protective layer 1 is 16 μm, the thickness of the barrier layer 2 is 7 μm, and the thickness of the heat-sealing layer 3 is 70 μm.

[0041] In this embodiment, the heat-sealing layer 3 is blow-molded by blow-molding equipment at a temperature of 165°C and an extrusion pressure of 50mpa after uniformly mixing the above-mentioned content of polybutene, metallocene LLDPE and HDPE. prepared. Wherein, the melt index of polybutene is 1 g / min, the melt index of metallocene LLDPE is 2 g / min, and the melt inde...

Embodiment 2

[0049] This embodiment provides a kind of aluminum foil sealing film, can refer to figure 1 As shown, it includes a protective layer 1, a barrier layer 2 and a heat-sealing layer 3 that are laminated sequentially from top to bottom. Wherein, the protective layer 1 is a varnish layer, the barrier layer 2 is an aluminum foil layer, and the heat-sealing layer 3 is composed of 25wt% polybutene, 50wt% metallocene LLDPE and 25wt% HDPE.

[0050] The thickness of the protective layer 1 is 12 μm, the thickness of the barrier layer 2 is 30 μm, and the thickness of the heat-sealing layer 3 is 45 μm.

[0051] In this embodiment, the heat-sealing layer 3 is blow molded by blow molding equipment at a temperature of 170°C and an extrusion pressure of 40mpa after uniformly mixing the above-mentioned content of polybutene, metallocene LLDPE and HDPE. prepared. Among them, the melt index of polybutene is 1.5 g / min, the melt index of metallocene LLDPE is 1.5 g / min, and the melt index of HDPE i...

Embodiment 3

[0059] This embodiment provides a kind of aluminum foil sealing film, can refer to figure 1 As shown, it includes a protective layer 1, a barrier layer 2 and a heat-sealing layer 3 that are laminated sequentially from top to bottom. Wherein, the protective layer 1 is a varnish layer, the barrier layer 2 is an aluminum foil layer, and the heat-sealing layer 3 is composed of 20wt% polybutene, 30wt% metallocene LLDPE and 50wt% HDPE.

[0060] The thickness of the protective layer 1 is 7 μm, the thickness of the barrier layer 2 is 50 μm, and the thickness of the heat-sealing layer 3 is 30 μm.

[0061] In this embodiment, the heat-sealing layer 3 is blow molded by blow molding equipment at a temperature of 185°C and an extrusion pressure of 35mpa after uniformly mixing the above-mentioned content of polybutene, metallocene LLDPE and HDPE. prepared. Wherein, the melt index of polybutene is 2 g / min, the melt index of metallocene LLDPE is 1 g / min, and the melt index of HDPE is 0.5 g / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com