Nitrogen-oxygen separation device

A technology of nitrogen and oxygen separation and molecular sieve, which is applied in the field of oxygen generators, can solve the problems of complex structure and low oxygen production efficiency, and achieve the effect of simplifying the structure and improving the efficiency of oxygen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The preferred embodiments of the present invention will be described in detail below with reference to the drawings.

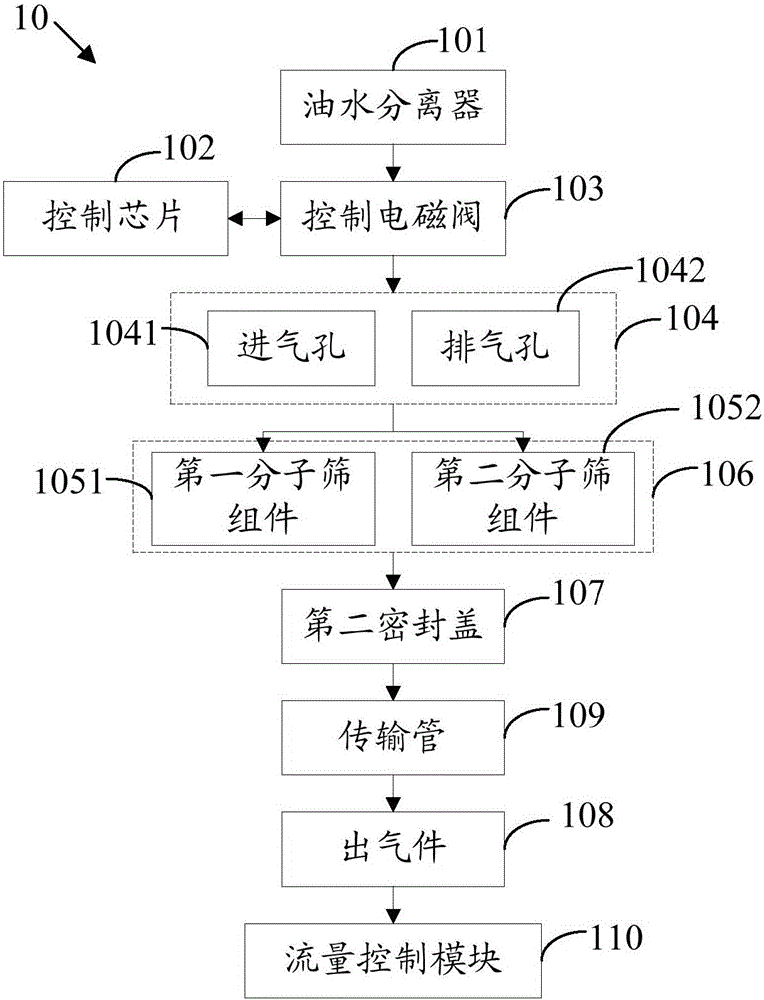

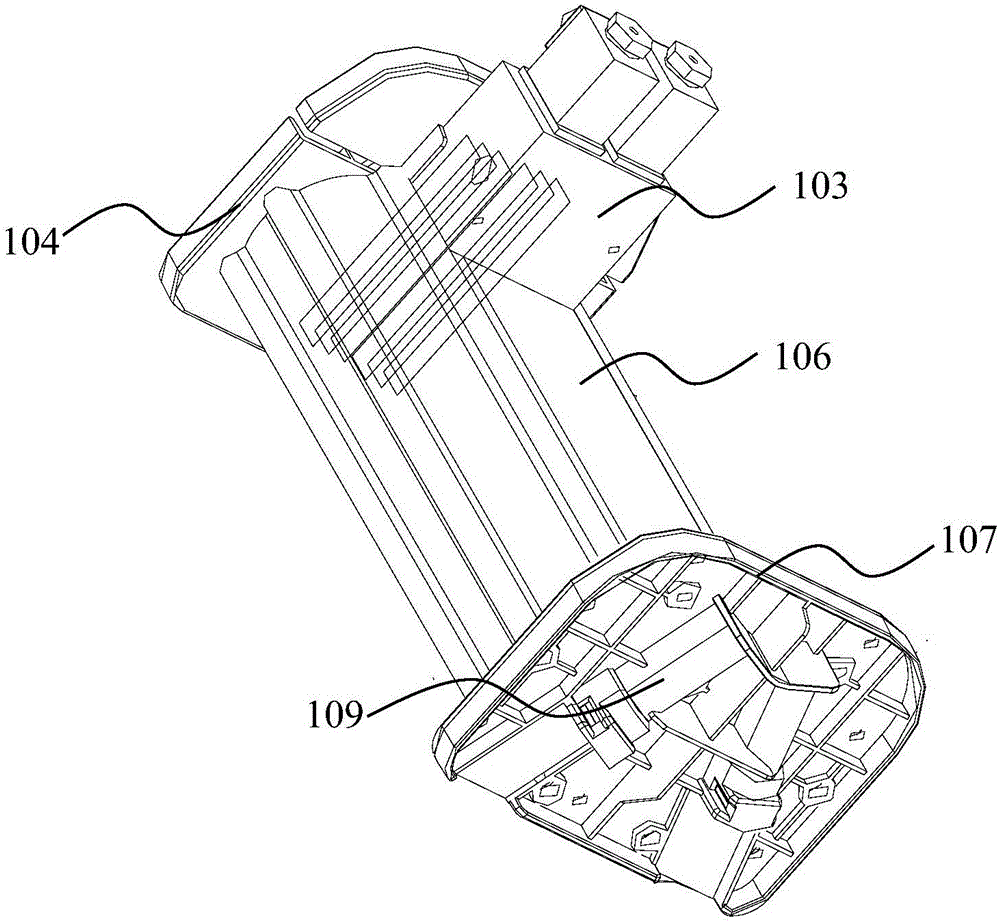

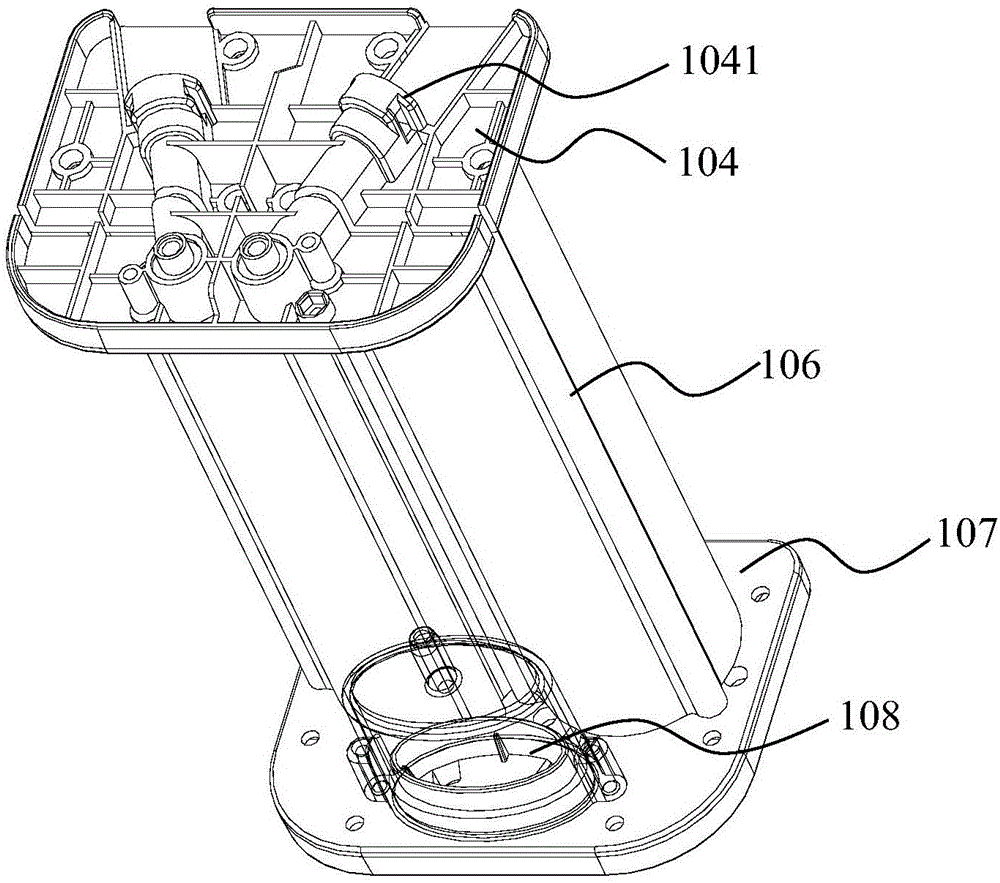

[0060] Please refer to figure 1 , figure 1 It is a structural block diagram of a preferred embodiment of the nitrogen and oxygen separation device of the present invention. The nitrogen and oxygen separation device 10 includes a first sealing cover 104, at least two molecular sieve assemblies, a molecular sieve body 106, a second sealing cover 107, an air outlet 108, a control chip 102, a control solenoid valve 103, a flow control module 110 and an oil-water separator 101.

[0061] The first sealing cover 104 is provided with an inlet hole 1041 for feeding compressed air and an exhaust hole 1042 for discharging separated nitrogen; a molecular sieve assembly, such as the first molecular sieve assembly 1051, is used for nitrogen and oxygen separation; the molecular sieve main body 106 is arranged on the periphery of the molecular sieve assembly; the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com