Sludge treating method and apparatus

A sludge treatment and sludge technology, applied in sludge treatment, water/sludge/sewage treatment, oxidation treatment of sludge, etc., can solve the problems of increased management difficulty, increased energy consumption, short time, etc. Reduction of refractory organics, increase in equipment requirements, and simplification of organics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

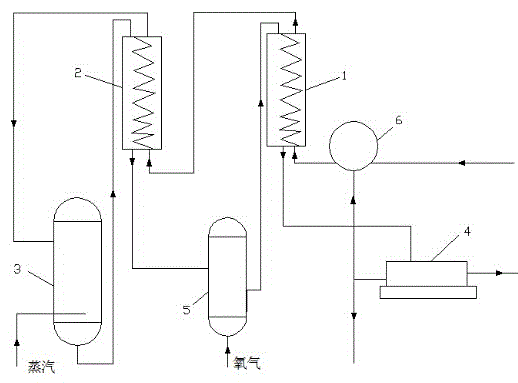

[0026] In order to understand the purpose, technical solutions and beneficial effects of the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following embodiments.

[0027] This embodiment provides a sludge treatment device, comprising:

[0028] The two-stage heat exchange device is heat exchange device A1 and heat exchange device B2. The heat exchange device A1 and the heat exchange device B2 are respectively provided with at least two mutually isolated channels, and the first channel outlet of the heat exchange device A1 is connected to the The first channel inlet of the heat exchange device B2 is communicated;

[0029] Thermal hydrolysis reaction device 3, the end outlet of the first passage of the heat exchange device B2 communicates with the inlet of the thermal hydrolysis reaction device 3, and the outlet of the ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com