Montmorillonite internal curing agent modified by vinyl carboxylate copolymer and preparation method for montmorillonite internal curing agent

A technology of carboxylic acid vinyl copolymer and sodium montmorillonite, which is applied in the field of concrete admixtures, can solve the problems of excessive air-entrainment, poor cement compatibility, and low water-reducing rate, and achieve obvious curing effect and water-reducing The effect of high efficiency and reduced investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

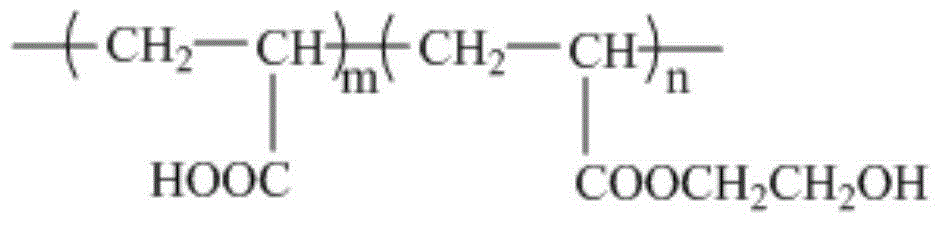

Method used

Image

Examples

Embodiment 1

[0021] Formula: 10% sodium montmorillonite, 48% deionized water, 12% carboxylic acid vinyl copolymer, 7% sodium gluconate, 23% sodium polyacrylate, in terms of mass percentage, the same below.

[0022] Preparation:

[0023] First, dissolve sodium-based montmorillonite, carboxylic acid vinyl copolymer, sodium polyacrylate, and sodium gluconate in deionized water, mix them evenly, heat them with hot air circulation at 55°C to 80°C for about 2-3 hours, and then put them Put it into an oven, dry at a constant temperature of 90°C-100°C for about 5 hours, and then grind to obtain a montmorillonite internal curing agent modified by a carboxylic acid vinyl copolymer.

Embodiment 2

[0025] Formula: 17% sodium montmorillonite, 51% deionized water, 14% carboxylic acid vinyl copolymer, 3% sodium gluconate, 15% sodium polyacrylate.

[0026] Preparation:

[0027] First, dissolve sodium-based montmorillonite, carboxylic acid vinyl copolymer, sodium polyacrylate, and sodium gluconate in deionized water, mix them evenly, heat them with hot air circulation at 55°C to 80°C for about 2-3 hours, and then put them Put it into an oven, dry at a constant temperature of 90°C-100°C for about 5 hours, and then grind to obtain a montmorillonite internal curing agent modified by a carboxylic acid vinyl copolymer.

Embodiment 3

[0029] Formula: 6% sodium montmorillonite, 44% deionized water, 19% carboxylic acid vinyl copolymer, 11% sodium gluconate, 20% sodium polyacrylate.

[0030] Preparation:

[0031] First, dissolve sodium-based montmorillonite, carboxylic acid vinyl copolymer, sodium polyacrylate, and sodium gluconate in deionized water, mix them evenly, heat them with hot air circulation at 55°C to 80°C for about 2-3 hours, and then put them Put it into an oven, dry at a constant temperature of 90°C-100°C for about 5 hours, and then grind to obtain a montmorillonite internal curing agent modified by a carboxylic acid vinyl copolymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com