Process for extracting curcumenol by molecular distillation method

A technology of molecular distillation and curcumol, which is applied in the direction of organic chemistry, can solve the problems of unsatisfactory yield and purity, and achieve high-purity results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

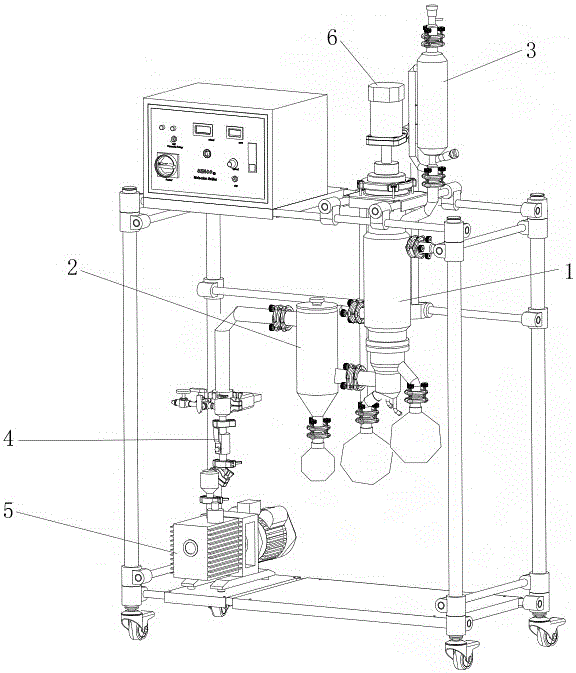

Image

Examples

Embodiment 1

[0020] A kind of technique of extracting curcumol by molecular distillation of the present invention, molecular still 1 is cleaned with ethanol in advance, dry, add 500 grams of commercially available curcuma oil in feed unit 3, first under the vacuum degree of 1.3mbar at normal temperature Degas for 25 minutes, until the zedoary oil in the feed unit 3 no longer bubbles, turn on the condensed water and the oil bath heater, the condensation temperature is -5°C, the oil bath heating temperature is 70°C, and after the temperature is stable, turn on the scraping and stirring , adjust the rotating speed to be 150rpm, and the vacuum is 1.2mbar. Then, slowly add turmeric oil to the distiller dropwise from the feed unit 3, and control the flow rate to be 1.7 drops / second. After the dropwise addition, collect 290 grams of directly condensed fractions, 110 grams of externally condensed distillate, 40 grams of unevaporated residue, and 7 grams of degassed light components;

[0021] After...

Embodiment 2

[0023] A kind of technique of extracting curcumol by molecular distillation of the present invention, molecular still 1 is cleaned with ethanol in advance, dry, add 500 grams of commercially available curcuma oil in feed unit 3, first under the vacuum degree of 1.5mbar at normal temperature Degas for 28 minutes until the zedoary oil in the feeding unit 3 no longer bubbles, turn on the condensed water and the oil bath heater, the condensation temperature is 0°C, and the oil bath heating temperature is 75°C. After the temperature is stable, turn on the scraping and stirring. Regulating rotating speed is 180rpm, and vacuum is 1.2mbar, then, slowly add zedoary oil to distiller dropwise from feed unit 3, control flow rate is 2 drops / second, after dropwise, collect direct condensation distillate 280 grams, outside Set 110 grams of condensed fraction, 45 grams of unevaporated residue, and 8 grams of degassed light components;

[0024] After 45 grams of the unevaporated residual porti...

Embodiment 3

[0026] A kind of technique of extracting curcumol by molecular distillation of the present invention, molecular still 1 is cleaned with ethanol in advance, dry, add 500 grams of commercially available curcuma oil in feed unit 3, first under the vacuum degree of 1.8mbar at normal temperature Degas for 30 minutes, until the zedoary oil in the feeding unit 3 no longer bubbles, turn on the condensed water and the oil bath heater, the condensation temperature is 5°C, and the oil bath heating temperature is 80°C. After the temperature is stable, turn on the scraping and stirring. Regulating rotating speed is 200rpm, and vacuum degree is 1.3mbar, then, slowly add zedoary oil to distiller dropwise from feed unit 3, control flow rate is 2.3 drop / second, after dropwise, collect direct condensed distillate 298 grams, outside Set 117 grams of condensed fraction, 48 grams of unevaporated residue, and 9 grams of degassed light components;

[0027] After 48 grams of the unevaporated residual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com