Clothing-crease-resistant wet tissue, preparation method therefor and application thereof

A clothing and wrinkle technology, applied in the field of anti-wrinkle clothing wet wipes and its preparation, can solve the problems of easily damaged clothing fibers, reduce gloss and smoothness, unevenness, etc., to protect clothing fibers, improve gloss and smoothness, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

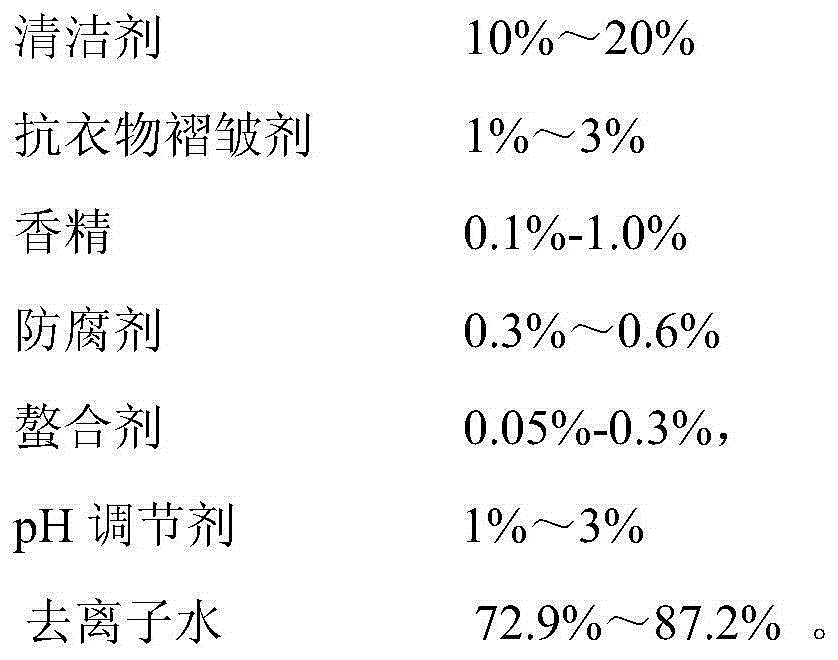

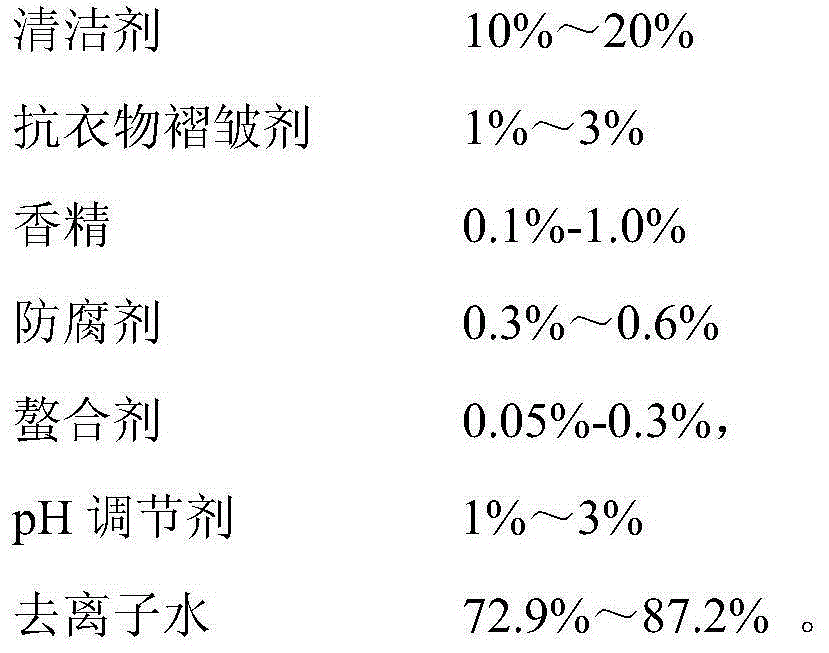

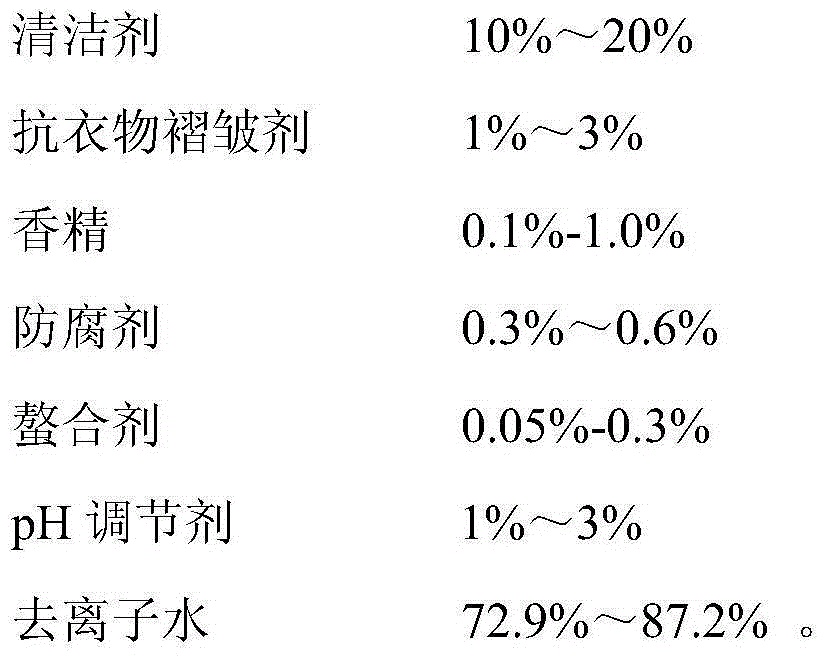

preparation example Construction

[0029] The preparation method of above-mentioned clothing wrinkle-resistant wet tissue, comprises the steps:

[0030] Step 1. Add 40%-50% of the deionized water of the formula into the stainless steel pot, then add the detergent of the formula, and stir for 25-30 minutes until uniform;

[0031] Step 2. Then add the anti-wrinkle agent in the prescribed amount, and stir for 15-20 minutes until uniform; then add the essence in the prescribed amount, and stir evenly;

[0032] Step 3. Keep stirring, add the remaining amount of deionized water, then add the chelating agent, and stir for 15-20 minutes until uniform;

[0033] Step 4: Add the pH adjuster in the formulated amount, adjust the pH to 7-8, then add the preservative, stir for 15-20 minutes until uniform, and obtain the mixed reagent;

[0034] Step 5. Import the mixed reagent obtained in Step 4 into the automatic wet tissue machine, put non-woven fabric in the automatic wet tissue machine, and produce the anti-wrinkle wet ti...

Embodiment 1

[0038] An anti-wrinkle wet wipe for clothing, which uses non-woven fabric as a base material and is produced in a fully automatic wet wipe machine with a mixed reagent, the pH of which is finally controlled at 7-8, and includes the following components in terms of mass percentage : 10% Sodium Alkylbenzene Sulfonate, 1% Wheat Protein / Silicone Copolymer, 0.2% Fragrance, 0.3% Phenoxyethanol, 0.3% Disodium EDTA, 1% Sodium Citrate, 87.2% Deionized Water.

Embodiment 2

[0040] An anti-wrinkle wet wipe for clothing, which uses non-woven fabric as a base material and is produced in a fully automatic wet wipe machine with a mixed reagent, the pH of which is finally controlled at 7-8, and includes the following components in terms of mass percentage : 12% Sodium Cocoamphoacetate, 1.5% Wheat Protein / Silicone Copolymer, 0.2% Fragrance, 0.3% Methylisothiazolinone, 0.3% Disodium EDTA, 1.2% Citric Acid, 84.5% Deionized Water .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com