High-strength road pile

A high-strength, road pile technology, applied in the direction of roads, roads, traffic restrictions, etc., can solve the problems of poor strength and complex processing technology, and achieve the effect of reducing product quality, improving corrosion resistance, and absorbing impact energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

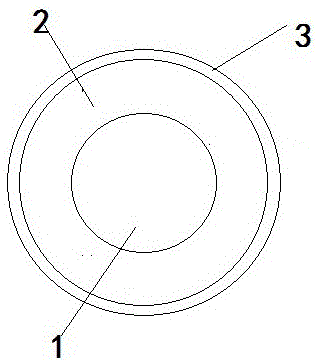

[0043] A high-strength road pile, the road pile is cylindrical, the core of the road pile is a particle-reinforced foamed aluminum-based composite material, the core is surrounded by an elastic material layer, the elastic material layer is a copper alloy cylinder, and the outer surface of the copper alloy cylinder is coated Covered with anti-corrosion paint, characterized by:

[0044] The particle-reinforced foamed aluminum-based composite material is prepared by the following preparation method:

[0045] Prepare an aluminum alloy ingot, its composition percentage is: Cu8﹪, Zn2﹪, Fe0.4﹪, Co0.3﹪, Ni0.1﹪, Ti0.05﹪, Y0.02﹪, Ag0.01﹪, the balance is Al ;

[0046] Melt the above-mentioned aluminum alloy and raise the temperature to 700°C-760°C, pass through protective Ar gas to refine and keep it warm for 10 minutes;

[0047] Add thickener accounting for 6-7% of the total weight of the melt and add silicon carbide and / or alumina particles accounting for 10-12% of the mass fraction ...

Embodiment 2

[0056] A high-strength road pile, the road pile is cylindrical, the core of the road pile is a particle-reinforced foamed aluminum-based composite material, the core is surrounded by an elastic material layer, the elastic material layer is a copper alloy cylinder, and the outer surface of the copper alloy cylinder is coated Covered with anti-corrosion paint, characterized by:

[0057] The particle-reinforced foamed aluminum-based composite material is prepared by the following preparation method:

[0058] Prepare an aluminum alloy ingot, its composition percentage is: Cu9﹪, Zn3﹪, Fe0.5﹪, Co0.4﹪, Ni0.2﹪, Ti0.06﹪, Y0.03﹪, Ag0.02﹪, the balance is Al ;

[0059] Melt the above-mentioned aluminum alloy and raise the temperature to 700°C-760°C, pass through protective Ar gas to refine and keep it warm for 10 minutes;

[0060] Add thickener accounting for 6-7% of the total weight of the melt and add silicon carbide and / or alumina particles accounting for 10-12% of the mass fraction ...

Embodiment 3

[0069] A high-strength road pile, the road pile is cylindrical, the core of the road pile is a particle-reinforced foamed aluminum-based composite material, the core is surrounded by an elastic material layer, the elastic material layer is a copper alloy cylinder, and the outer surface of the copper alloy cylinder is coated Covered with anti-corrosion paint, characterized by:

[0070] The particle-reinforced foamed aluminum-based composite material is prepared by the following preparation method:

[0071] Prepare the aluminum alloy ingot, its composition percentage is: Cu8.5﹪, Zn2.5﹪, Fe0.45﹪, Co0.35﹪, Ni0.15﹪, Ti0.055﹪, Y0.025﹪, Ag0.015﹪, The balance is Al;

[0072] Melt the above-mentioned aluminum alloy and raise the temperature to 700°C-760°C, pass through protective Ar gas to refine and keep it warm for 10 minutes;

[0073] Add thickener accounting for 6-7% of the total weight of the melt and add silicon carbide and / or alumina particles accounting for 10-12% of the mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com