Integral wall and construction process thereof

An integral, wall panel technology, applied in the direction of walls, building materials, building components, etc., can solve the problems of wasting energy, polluting the environment, poor flatness, etc., achieving the effect of simple construction process operation, simple overall structure, and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 .

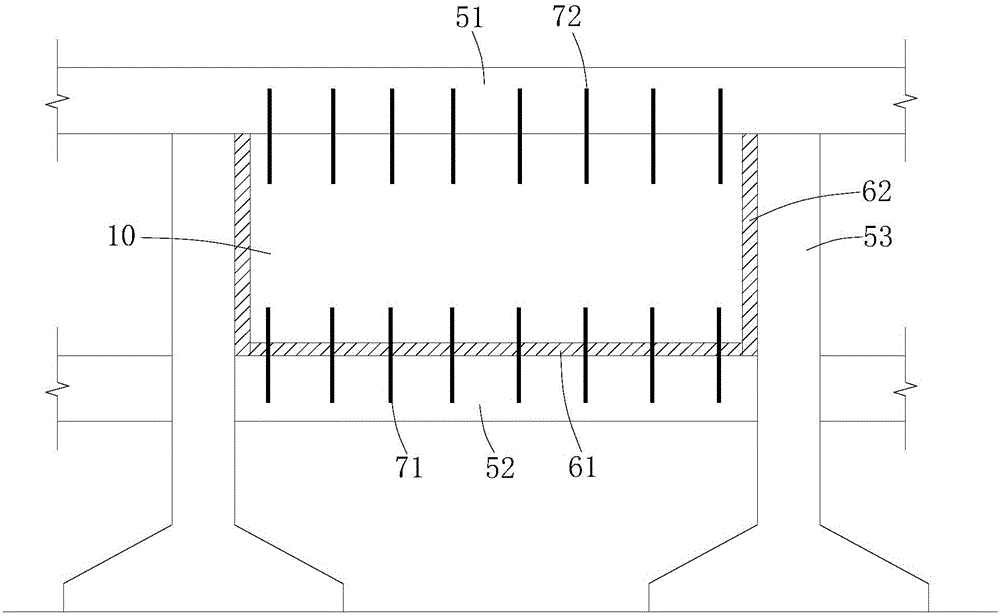

[0036] The integral wall includes a load-bearing frame composed of an upper load-bearing beam 51, a lower load-bearing beam 52, and two load-bearing columns 53 connected between the upper load-bearing beam 51 and the lower load-bearing beam 52, and the integral wall also includes a prefabricated wall panel 10, The prefabricated wall panel 10 is installed between the upper load-bearing beam 51, the lower load-bearing beam 52 and two load-bearing columns 53, and the lower side of the prefabricated wall panel 10 passes through the first vibration isolation pad 61 and the lower load-bearing beam. 52, the left and right sides of the prefabricated wall panel 10 are respectively connected to the inner surfaces of the two load-bearing columns 53 through the second shock-isolating pad 62, and the lower load-bearing beam 52 is connected to the prefabricated wall panel 10 are provided with a plurali...

Embodiment 2

[0045] see Figure 7 .

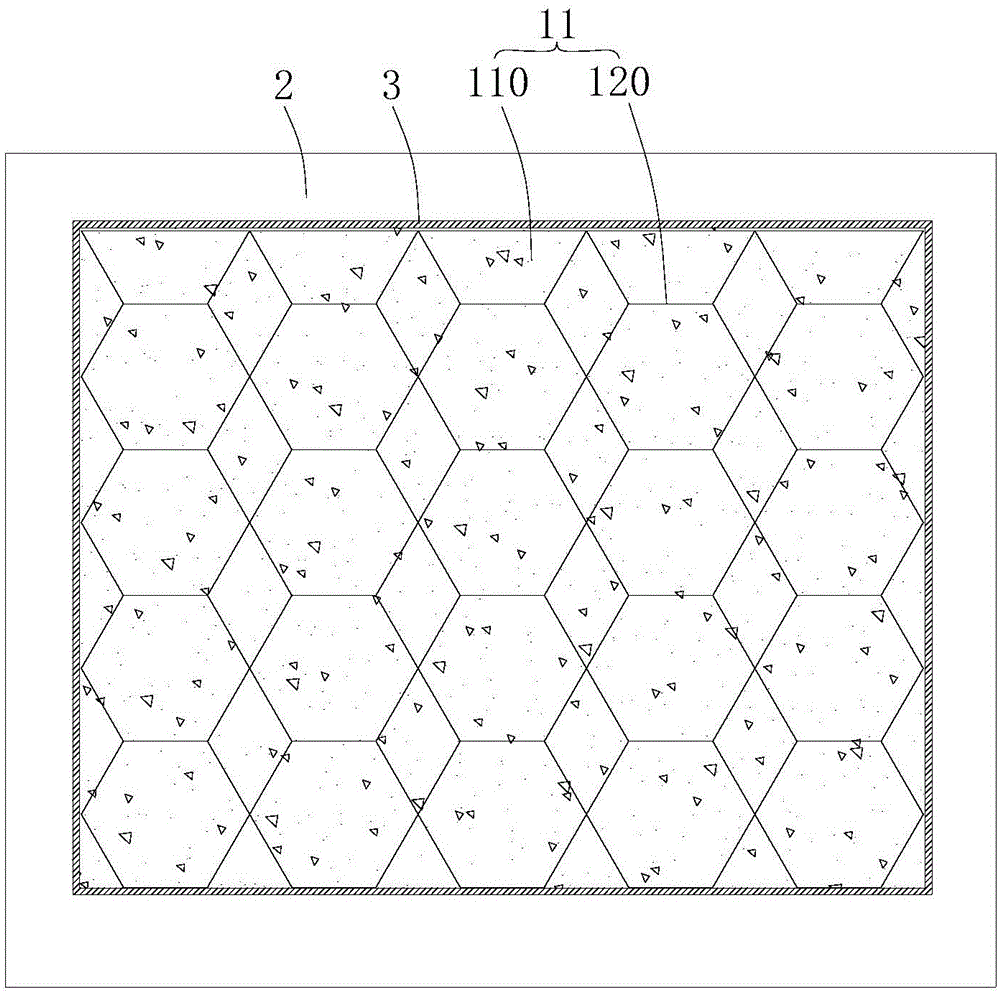

[0046] This embodiment is similar to Embodiment 1, so only the differences will be described. Their difference lies in that: the plurality of fiber units 120 are arranged in honeycomb and filled in the foamed concrete matrix 110 . The honeycomb structure is a very high-strength structure, and this arrangement can also improve the strength of the present invention.

Embodiment 3

[0048] see Figure 8 .

[0049] This embodiment is similar to Embodiment 1, so only the differences will be described. Their difference is that: the prefabricated wall panel 10 is provided with a hole 4 for installing a door, the hole wall of the hole 4 is covered with a hole wall reinforced frame plate 41, and the hole wall reinforced frame plate 41 is made of reinforced concrete production. According to the design requirements, some filling walls need to open holes 4 for installing doors, and the set hole wall reinforcement frame plate 41 can not only enhance the strength and stability of the holes 4, but also provide a A stable mount. In this embodiment, the lower end of the hole 4 extends to the lower side of the prefabricated wall panel 10 to form an opening, and the upper end of the hole 4 is close to the upper side of the prefabricated wall panel 10, so that the upper and lower ends of the hole wall reinforced frame plate 41 are in contact with the outer reinforced f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com