Method for testing residual stress distribution of ram casting for large-scale machine tool by blind hole method

A residual stress and blind hole method technology, applied in the direction of measuring force, measuring device, instrument, etc., can solve the problems of high cost, expensive equipment, complicated calculation, etc., and achieve the effect of low cost, perfect theory and simple calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

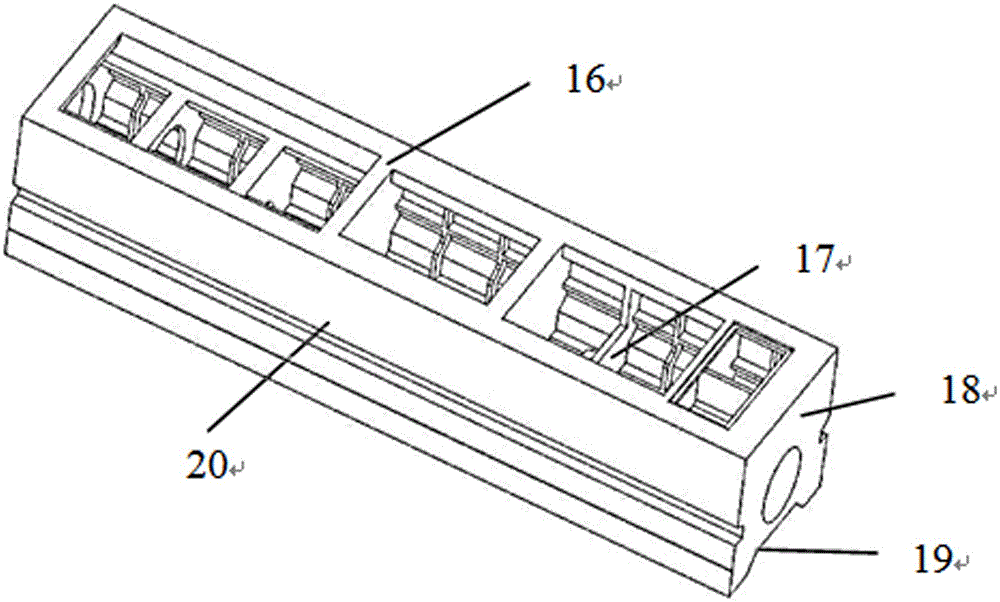

[0025] A method for testing the residual stress distribution of a ram casting for a large machine tool by using the blind hole method, comprising the following steps:

[0026] 1) Take the ram casting out of the mold, remove the excess parts other than the body, and polish the inner and outer surfaces of the casting;

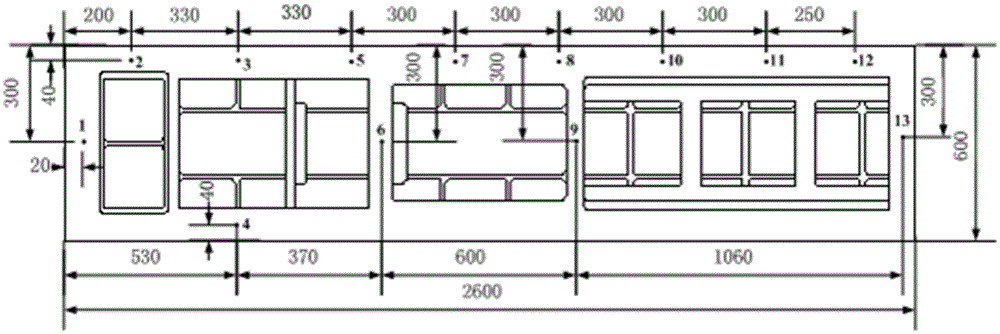

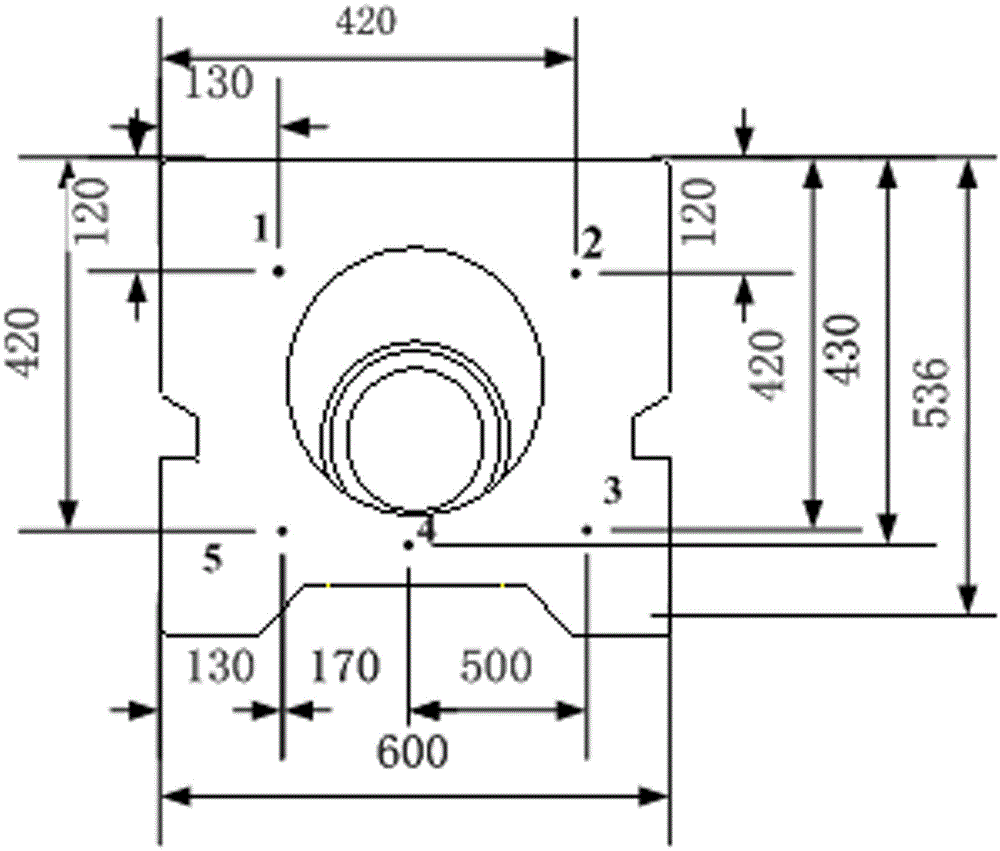

[0027] 2) Analyze the structure of the ram casting, select the residual stress test surface, and polish and clean each surface, and then arrange the residual stress measurement points;

[0028] 3) Test the strain caused by the residual stress at each test point;

[0029] 4) Analyze and integrate the strain data obtained from the test, use the residual stress calculation formula to calculate the residual stress value at each point, and finally obtain the residual stress distribution of the ram casting through curve fitting, and the result deviation is ±5Mpa.

[0030] Step 1) is specifically to remove the core and core iron on the ram casting, cut off the gate, ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| gauge factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com