Device structure with grapheme as contact electrode and manufacturing method thereof

A graphene electrode and device structure technology, applied in the field of microelectronics, can solve the problems of electrode contact resistance affecting device performance, lattice damage, material surface pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Please refer to the attached Figure 1-16 As shown, the present invention provides a kind of device structure preparation method using graphene as contact electrode, and the specific implementation method is as follows:

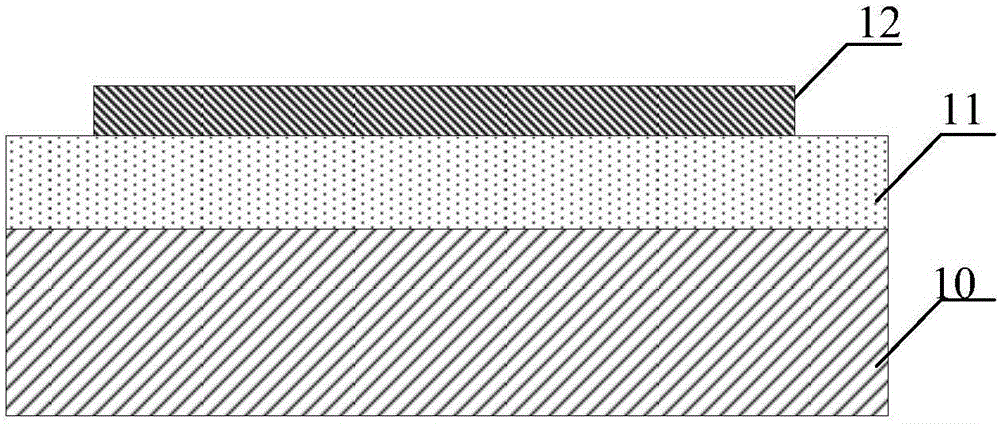

[0048] Step 1, forming a polypropylene carbonate PPC film 11 on the first substrate 10; PPC is coated on the first substrate 10 at 1500r / min with a glue leveler, and heated at 120 degrees for 3-5min until it is cured to form a film; then a mechanically peeled first h-BN film 12 is formed on the PPC film. A PPC-h-BN structure on the first substrate is formed. see figure 1 shown.

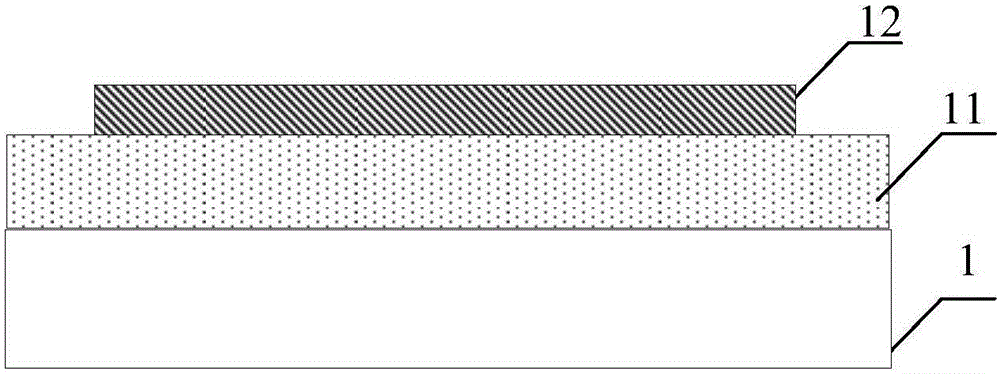

[0049] In step 2, peel off the PPC-h-BN structure on the first substrate 10 and place it on the PDMS film 1 to form a PDMS-PPC-h-BN structure. The surface of the PDMS film 1 and the PPC film is smooth and elastic. Since the PDMS film is relatively thick, it plays a supporting role in the subsequent dry transfer process and can be well adhered to the PPC film by van der Wa...

Embodiment 2

[0065] The present invention also provides another device structure preparation method using graphene as a contact electrode, which at least includes the steps:

[0066] a) see Figure 17 As shown, a polypropylene carbonate PPC film 11' is formed on the first substrate 10'; PPC is coated on the first substrate 10' at 1500r / min with a glue leveler, and heated at 120 degrees for 3 -5min until solidified into a film; then form a mechanically peeled h-BN film 12' on the PPC film 11';

[0067] b) Peel off the PPC-h-BN on the first substrate 10', and put it on the PDMS elastic film 1' with support and adhesion, please refer to the attached Figure 18 shown.

[0068] c) MoS is formed on the second substrate 30' 2 Film 31'; see Figure 19 shown.

[0069] d) Adsorption of MoS in step c) with the PDMS-PPC-h-BN structure 2 thin film; obtain PDMS—PPC—h-BN—MoS 2 structure; see Figure 20 and Figure 21 shown.

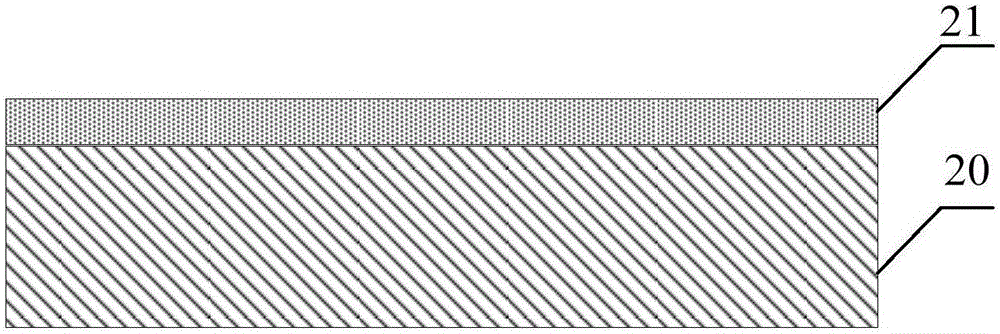

[0070] e) see Figure 22 and 23 As shown, a graphene film 21' is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com