Sr-Pb binary metal composite perovskite material, and preparation and application method thereof

A composite perovskite and binary metal technology, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, organic semiconductor devices, etc., can solve the environmental friendliness of perovskite batteries and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

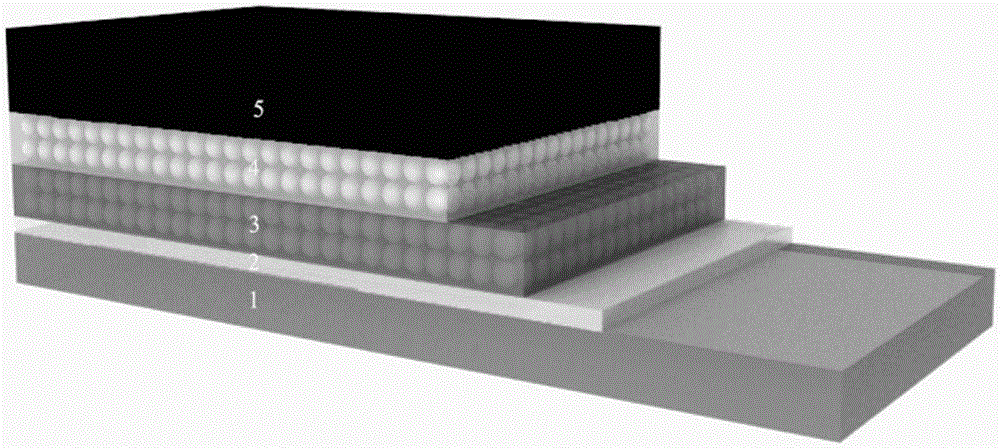

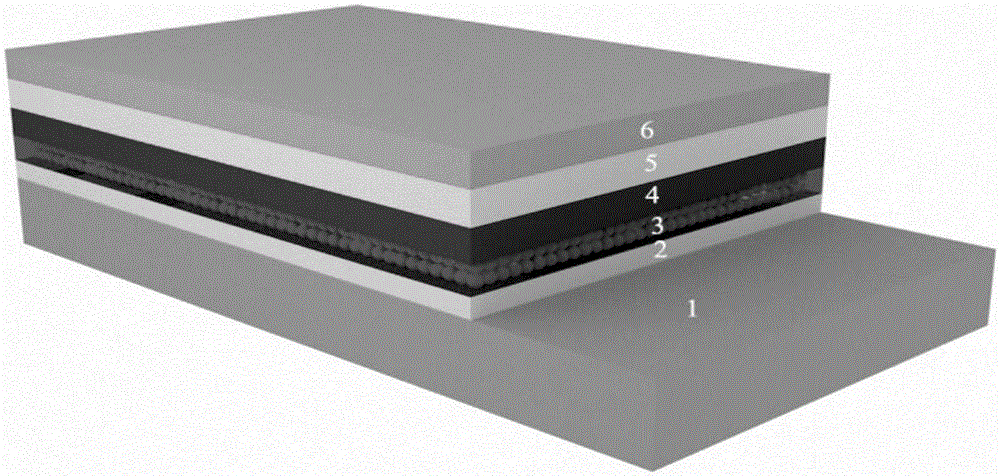

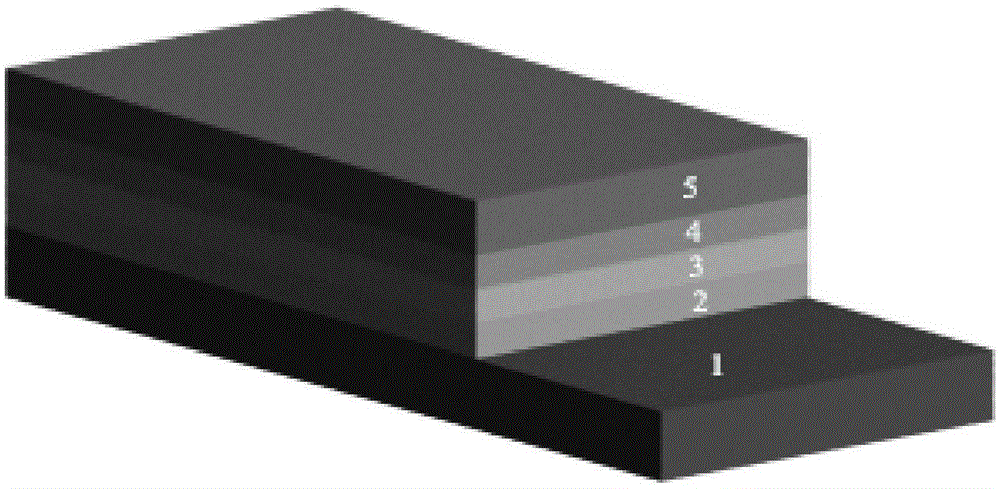

Method used

Image

Examples

Embodiment 1

[0070] Embodiment 1, comprises the steps:

[0071] (1) PbI with a molar ratio of 50% 2 with 50% molar ratio of SrCl 2 The powders are homogeneously mixed to form PbI 2 and SrCl 2 mixed powder;

[0072] (2) the PbI 2 and SrCl 2 Mix powder, with CH 3 NH 3 I crystals are proportioned in a molar ratio of 1:1 to form a mixture;

[0073] (3) Dissolving the mixture in N,N-dimethylformamide DMF solvent, stirring at 70°C until completely dissolved to obtain a Sr-Pb binary metal composite perovskite material; wherein, the mixture The mass ratio of the total mass of the material is 40%.

Embodiment 2

[0074] Embodiment 2, comprises the steps:

[0075] (1) PbCl with a molar ratio of 70% 2 with 30% molar ratio of SrI 2 The powders are homogeneously mixed to form PbCl 2 and SrI 2 mixed powder;

[0076] (2) the PbCl 2 and SrI 2 Mix powder, with CH 3 NH 3 Br crystals are mixed in a molar ratio of 1:2 to form a mixture;

[0077] (3) Dissolving the mixture in a gamma-butyrolactone solvent, stirring at 100°C until completely dissolved to obtain a Sr-Pb binary metal composite perovskite material; wherein, the mixture accounts for 1% of the total mass of the material The mass ratio is 50%.

Embodiment 3

[0078] Embodiment 3, comprises the steps:

[0079] (1) PbBr with a molar ratio of 90% 2 with 10% molar ratio of SrI 2 The powders are homogeneously mixed to form PbBr 2 and SrI 2 mixed powder;

[0080] (2) the PbBr 2 and SrI 2 Mix powder, with CH 3 NH 3 Cl crystals are mixed in a molar ratio of 1:1 to form a mixture;

[0081] (3) Dissolving the mixture in dimethyl sulfoxide DMSO solvent, stirring at 120° C. until completely dissolved to obtain a Sr-Pb binary metal composite perovskite material; wherein, the mixture accounts for the total mass of the material The mass ratio is 60%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com