Lip skin sector and method and apparatus for forming lip skin sector

A molding device, sector technology, applied in ground devices, transportation and packaging, aircraft power devices, etc., to achieve uniform flow, reduce manual workload, and reduce the risk of material deformation or deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

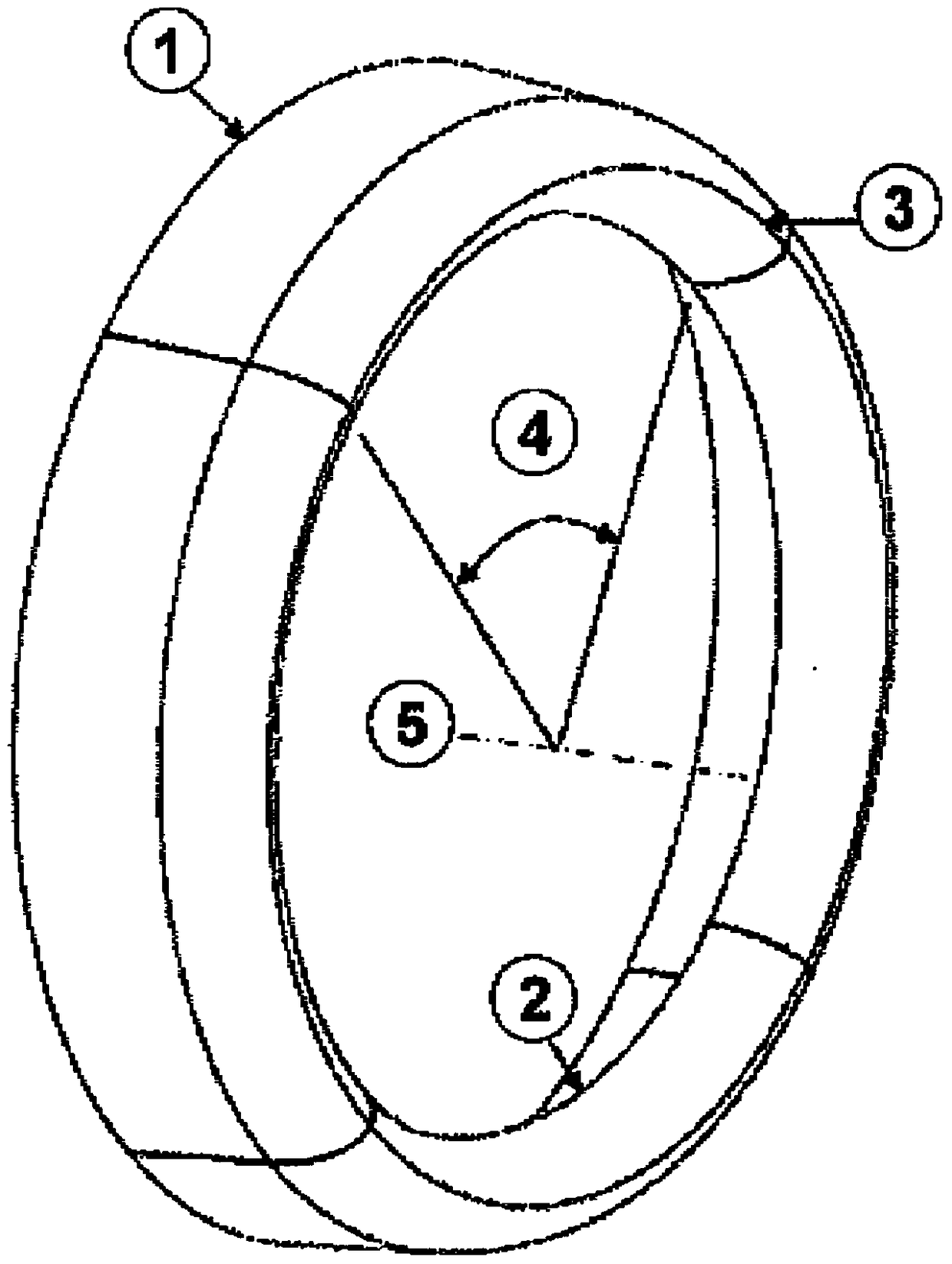

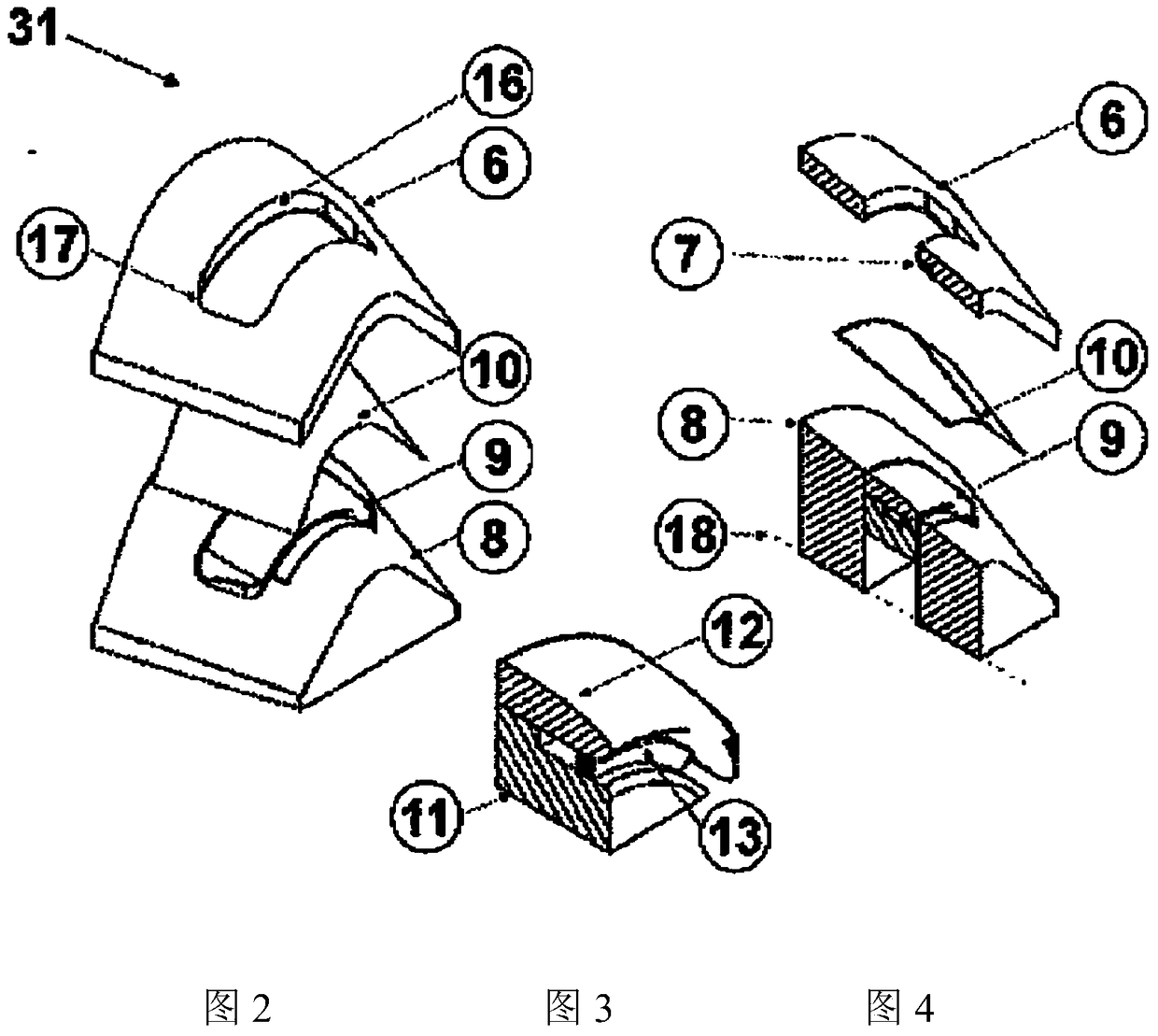

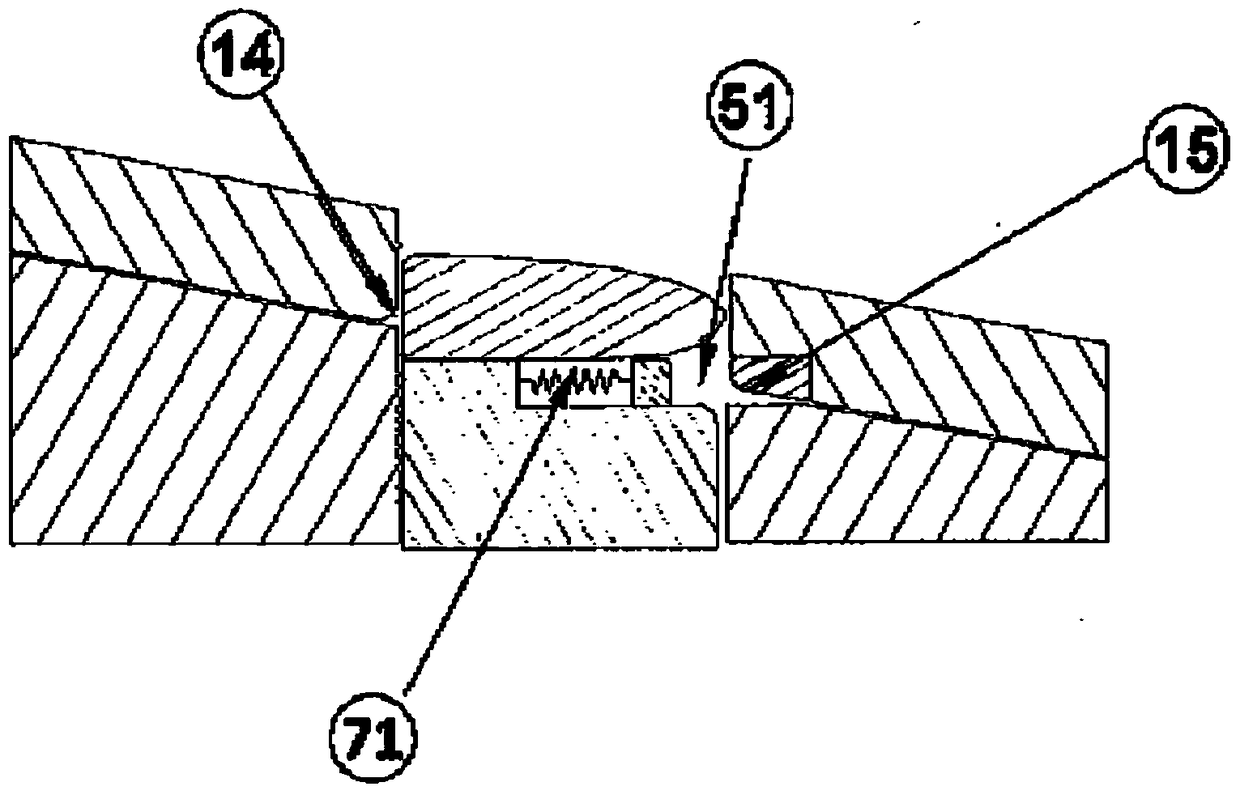

[0136] With reference to the attached drawings and first to the Figures 1 to 5F , shows a device generally indicated by reference numeral 31 for forming a sector of lip skin of an aircraft nacelle. The device 31 has a die plate 6 with a cast or machined surface supported by a further cast or machined structure, not shown, which transmits the force from the die plate 6 to the pressure system. The surface of the die plate 6 is made of a linearly extending conical section on each side. The surface of the die plate is designed to ensure uniform drawing on the surface of the punch 12 while providing sufficient clearance for the inner surface of the secondary drawing by utilizing the secondary drawing annular sector 7 . The cutout 16 in the center of the die plate 6 is shaped to match the shape of the punch 12 with a small clearance for the material blank thickness. The corners of the cutouts 16 are rounded 17 to ensure sufficient material flow to minimize buckling. The inner pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com