Electroless plating method and ceramic substrate

A ceramic substrate, non-electrolytic technology, applied in printed circuits, electrical components, liquid chemical plating, etc., can solve problems such as plating thickness fluctuations, and achieve the effect of improving module reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

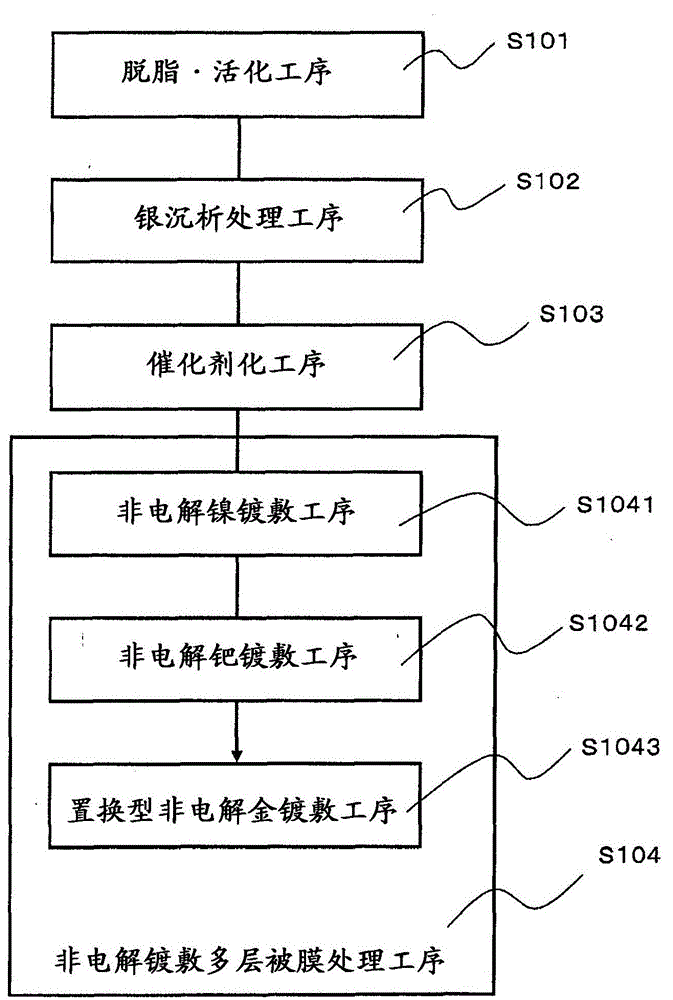

[0033] figure 1 It is a figure which shows the process flow of Embodiment 1 of this invention. figure 1 Among them, in terms of the electroless plating method in the glass-ceramic wiring board, it is the following method: the step of degreasing and activating the surface of the silver sintered body wiring pattern (step S101), the catalytic step (step S103), Electroless nickel plating process (step S1041), electroless palladium plating process (step S1042), and displacement type electroless gold plating process (step S1043), silver precipitation is carried out between the degreasing and activation process and the catalytic process. analysis process (step S102).

[0034] The electroless nickel plating process (step S1041), the electroless palladium plating process (step S1042), and the displacement type electroless gold plating process (step S1043) are collected as the electroless plating multilayer film treatment process (step S104).

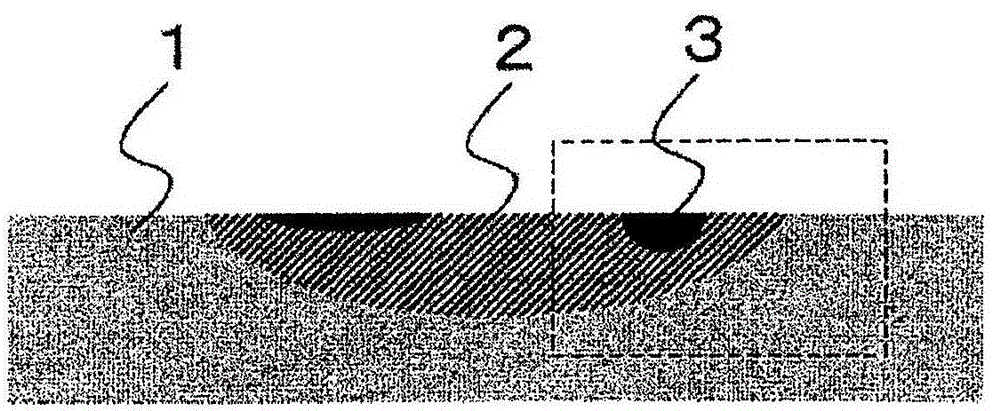

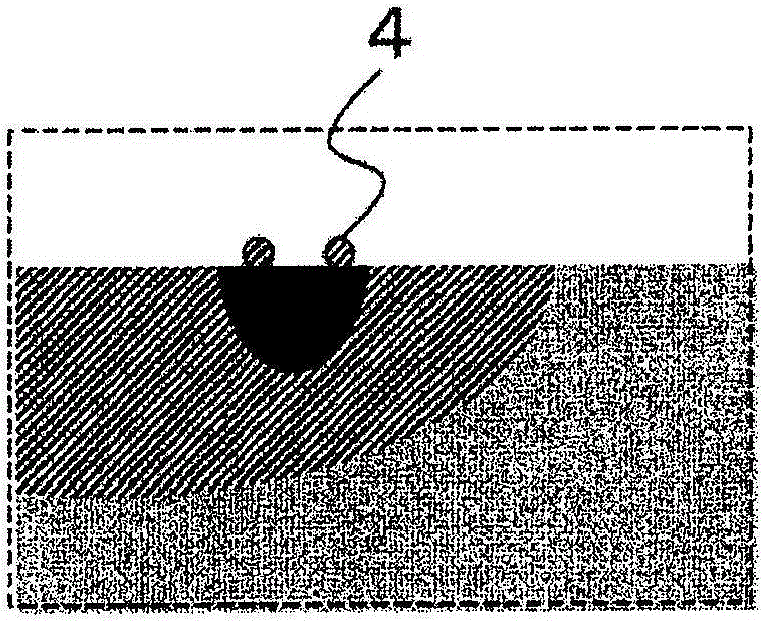

[0035] figure 2 It is a sectional vie...

Embodiment approach 2

[0079] Figure 9 It is a figure which shows the process flow of Embodiment 2 of this invention. In the previous Embodiment 1, the degreasing and activation process, the silver precipitation treatment process, the catalystization process, the electroless nickel plating process, the electroless palladium plating process, and the displacement type electroless gold plating process were performed in the order of The method of electrolytic plating is described. On the other hand, in Embodiment 2, in addition to Embodiment 1 above, a case where a glass etching step is performed between the electroless nickel plating step and the electroless palladium plating step will be described.

[0080] Between the silver sintered body wiring patterns 2 of Embodiment 1 above, if the pattern interval is narrow, for example, within 10 μm, palladium may be abnormally deposited on the deposited silver in the electroless palladium plating process, resulting in a pattern. short circuit between. Ther...

Embodiment approach 3

[0106] Figure 10 It is a figure which shows the process flow of Embodiment 3 of this invention. The method of performing electroless plating in the order of the electroless nickel plating step, the electroless palladium plating step, and the displacement type electroless gold plating step in the electroless plating multilayer film treatment step in the first embodiment Be explained. On the other hand, in Embodiment 3, the electroless plating multilayer film treatment step is performed in the order of electroless nickel plating step, displacement type electroless gold plating step, and reduction type electroless gold plating step. The method of plating will be described. Other configurations are the same as those in the first embodiment.

[0107] Figure 10 Among them, step S301, step S302, and step S303 are sequentially the same as those of the previous embodiment 1 figure 1 Step S101, step S102, and step S103 are the same process.

[0108] Next, step S304 of the electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com