Control system for rotary electric machine and method for controlling the same

A technology for controlling systems and rotating electrical machines, which is applied in the field of changing the effective magnetic flux of the rotor, and can solve the problems of increasing the size and cost of rotating electrical machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

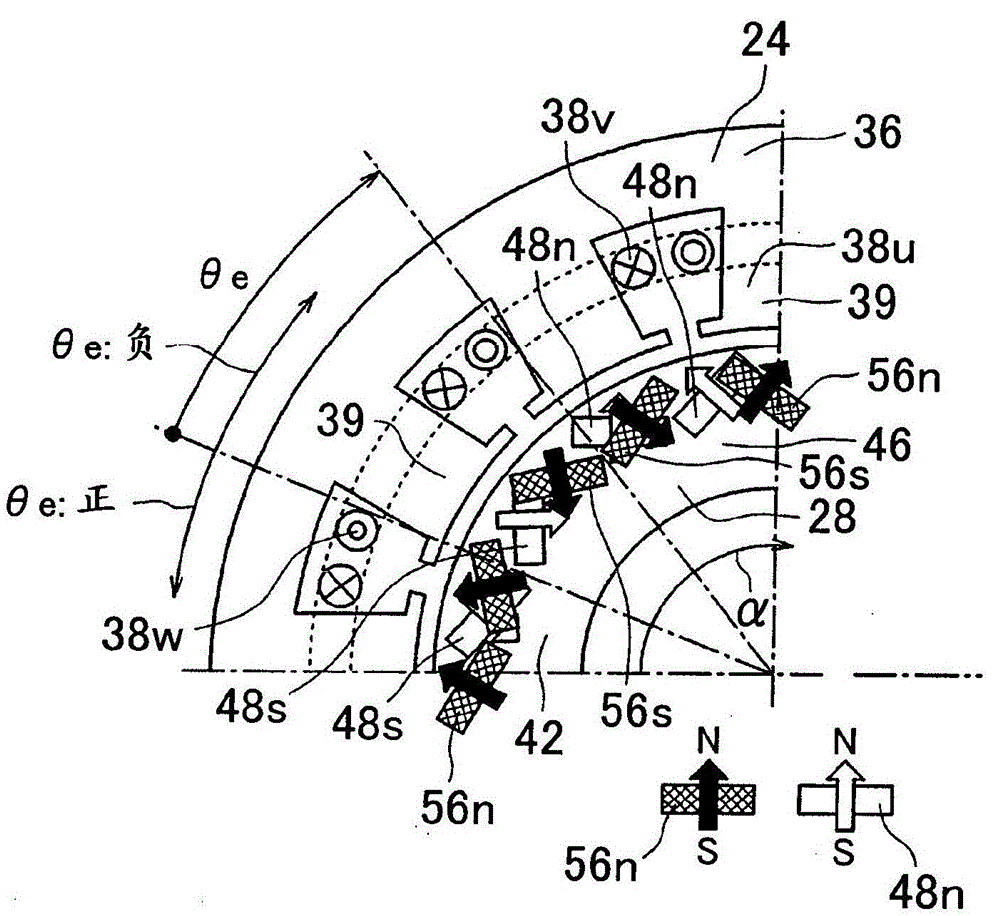

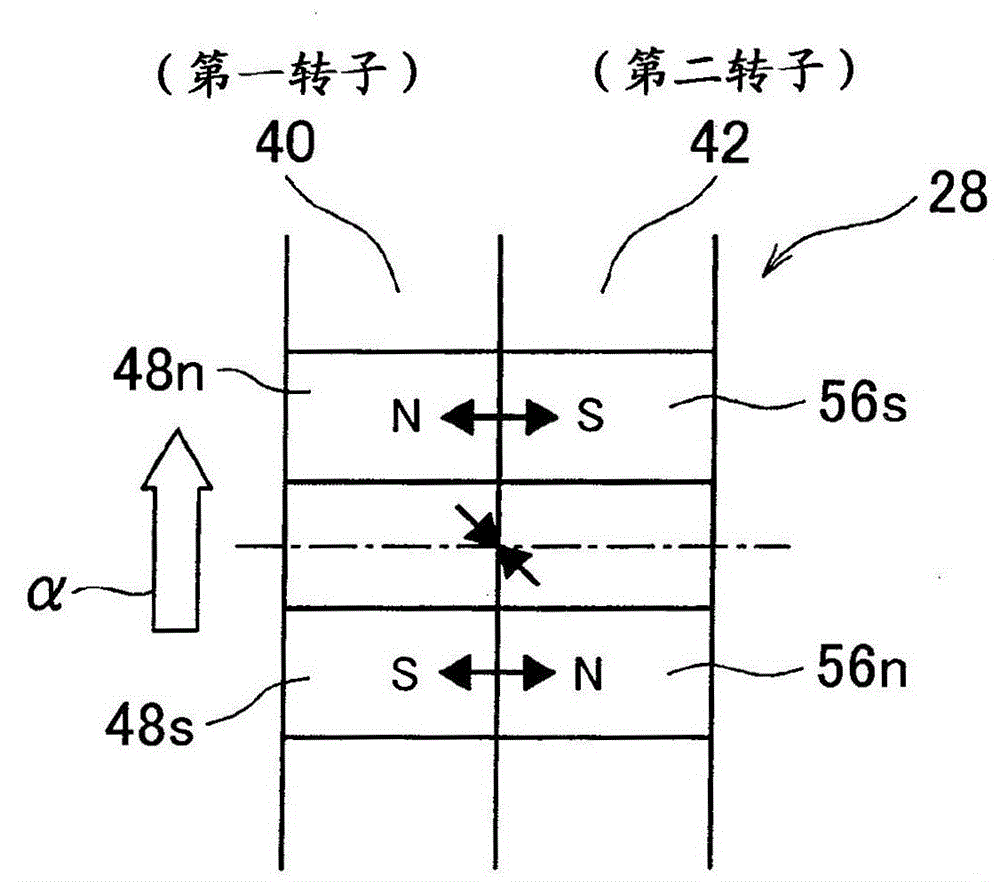

[0038] Embodiments of the present invention will be explained below with reference to the drawings. In the following, the same components are described using the same reference numerals in all figures.

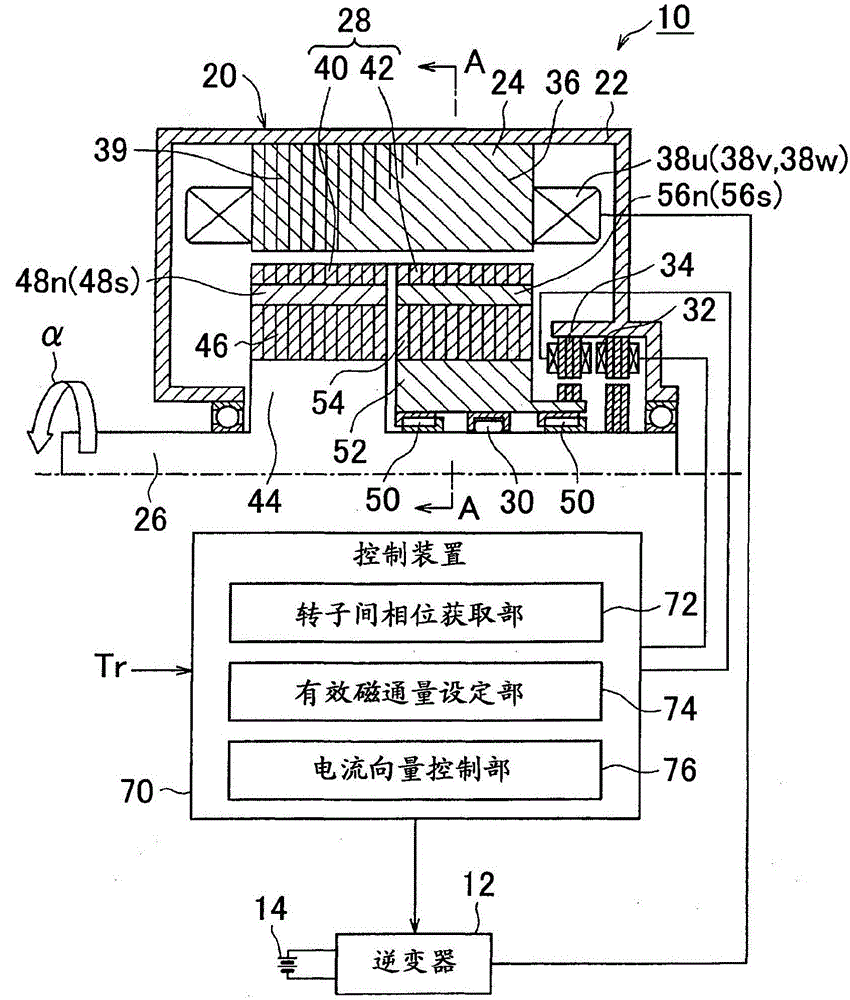

[0039] [first embodiment] figure 1 A rotating electrical machine control system 10 according to a first embodiment of the present invention is shown. The rotary electric machine control system 10 is equipped with a rotary electric machine 20 , an inverter 12 serving as a drive circuit, an electric storage device 14 serving as a power source, and a controller 70 . The rotating electrical machine control system 10 is mounted to an electric vehicle such as a hybrid vehicle, an electric vehicle, or a fuel cell vehicle, and is used to drive wheels (not shown) using the rotating electrical machine 20 as an electric motor. The rotary electric machine 20 can be used as a generator, a motor, or a motor-generator having both functions of a motor and a generator.

[0040]The rotary el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com