Rotary mop head with differential mechanism

A rotating mop head and mop technology, applied in the field of household sanitary ware, can solve the problems of increased assembly time, difficulty in controlling the rotation speed, and difficult realization of functions, etc., and achieve the effects of optimized transmission structure, reliable structural design, and stable and reliable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

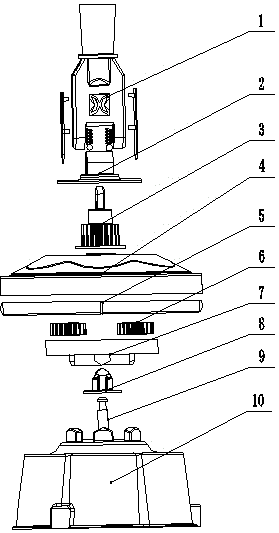

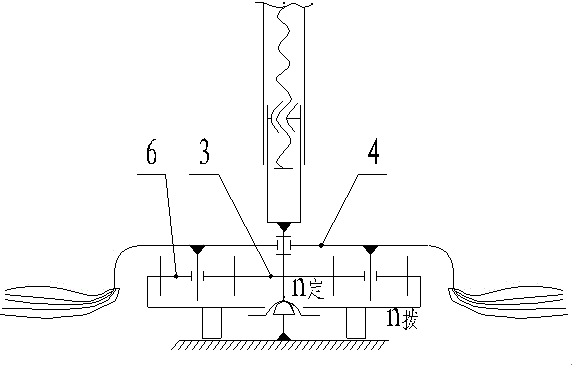

[0027] Such as figure 1 , figure 2 with image 3 As shown, the present invention is a rotary mop head with a differential mechanism, which includes a mop rod connector 1, an annular positioning ferrule 2, a centering gear shaft 3, a mop rotating disc 4, a cotton yarn fixing disc 5, and a differential gear 6 and differential fork ring gear 7. Such as Figure 4 with Figure 5 As shown, the upper end of the mop rod connector 1 is fixedly connected with the mop rod, and the lower end is jointly hinged with the annular positioning ferrule 2 and the centering gear shaft 3 . The inner cavity of the annular positioning ferrule 2 and the centering gear shaft 3 are interference fit. Such as figure 2 As shown, the mop rotating disk 4 is fixed between the annular positioning ferrule 2 and the centering gear shaft 3, and two positioning shafts are symmetrically distributed along the axis inside it. There are two differential gears 6, which are respectively sleeved on two positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com