Air filter

An air filter and filter element technology, which is applied in the fields of dispersed particle filtration, chemical instruments and methods, and dispersed particle separation, can solve the problems of low filtration efficiency, small dust holding capacity and large resistance, and achieve high filtration efficiency and dust holding capacity. The effect of large volume and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

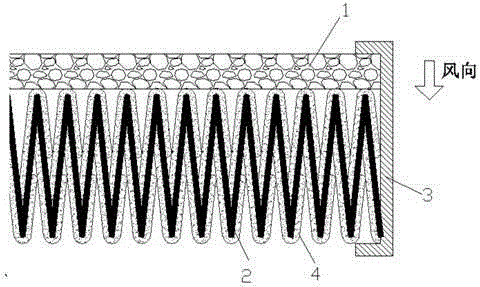

[0047] Provide a PM2.5 air filter, the net size of the windward side is 595mm*625mm, and the rated air volume is 2000m 3 / h, head-on wind speed 1.5m / s, design efficiency 90%, initial pressure loss ≤ 40Pa, dust holding capacity 600g when 2.5 times the initial pressure loss.

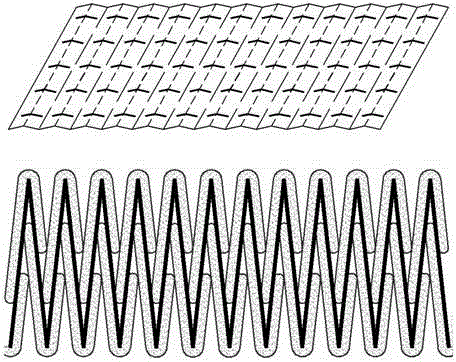

[0048] The filter adopts the combined structure of coarse-effect non-woven fabric and high-efficiency filter element: the thickness of coarse-effect non-woven fabric 1 is 15mm, the weight efficiency is 60%, the initial pressure loss is 12Pa at 1.5m / s, and the dust holding capacity at 2.5 times the initial pressure loss ( ISOA2 dust) 850g / ㎡; the thickness of the non-woven fabric used in the high-efficiency filter element 2 is 0.5mm, and the filtration efficiency of 0.5μm air dust is 92.5% at a wind speed of 0.08m / s, and the pressure loss is 10Pa.

[0049] The non-woven material used in the high-efficiency non-woven fabric filter element 2 is polyester. After the polyester non-woven fabric is reciprocally pl...

Embodiment 2

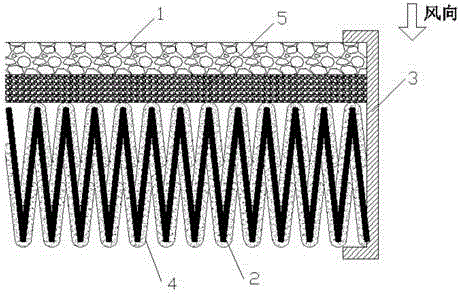

[0053] Provide a PM2.5 air filter, the net size of the windward side is 595mm*625mm, and the rated air volume is 2000m 3 / h, head-on wind speed 1.5m / s, design efficiency 95%, initial pressure loss ≤ 70Pa, dust holding capacity 800g when 2.5 times the initial pressure loss.

[0054] The filter adopts a three-layer combination structure of a layer of coarse-effect non-woven fabric, a layer of medium-efficiency non-woven fabric and a high-efficiency filter element: the thickness of coarse-effect non-woven fabric 1 is 15mm, the weight efficiency is 50%, and the initial pressure loss is 1.5m / s 12Pa, 2.5 times the initial pressure loss, the dust holding capacity is 700g / ㎡; the thickness of the medium-efficiency non-woven fabric 5 is 10mm, the weight efficiency is 70%, the initial pressure loss is 18Pa, and the capacity is 2.5 times the initial pressure loss at 1.5m / s. The dust volume is 400g / ㎡, and the thickness of the filter material used in the high-efficiency filter element 2 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com