Water-based extinguishing agent manufacture equipment

A fire extinguishing agent, water system technology, applied in fire prevention equipment, dissolution, chemical/physical/physical-chemical stationary reactors, etc. To achieve the effect of complete dissolution, high degree of automation and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

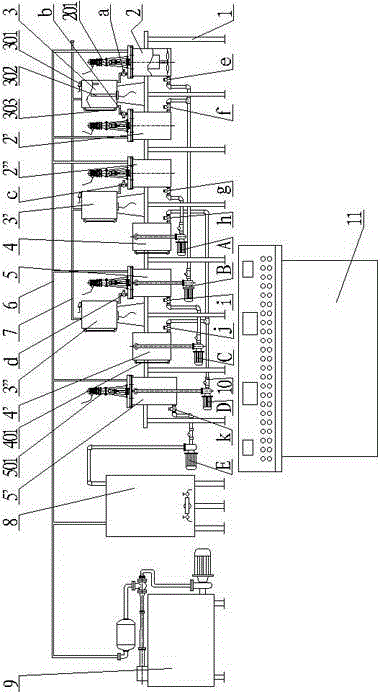

[0023] Below in conjunction with accompanying drawing, present embodiment is further explained:

[0024] as attached figure 1 Shown, the first reactor 2, the second reactor 2', the third reactor 2", the fourth reactor 5, the fifth reactor 5', the first tank 3, the second tank 3', the third tank 3", the first fixed container 4 and the second fixed container 4' are fixed on the frame 1; the finished product tank 8, the water jet vacuum unit 9 for recycling and treating waste gas, and the computer program console 11 are placed beside the frame 1; The first reaction kettle 2, the second reaction kettle 2', and the third reaction kettle 2" are respectively equipped with a high magnetic stirrer 201; the fourth reaction kettle 5 and the fifth reaction kettle 5' are respectively equipped with a high-shear agitator 501 Electric heating rod 302, liquid level sensor 303 and temperature sensor 301 are respectively provided in the first water tank 3, the second water tank 3', the third wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com