Full-automatic solar array air pressure water/steam dual-purpose cleaning system

A solar array and cleaning system technology, applied in the field of fully automatic solar array air-pressure water/steam dual-purpose cleaning system, can solve the problems of complicated mechanical operation, easy crushing of solar panels, and difficulty in controlling distance and pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

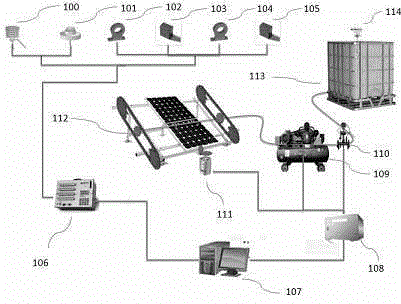

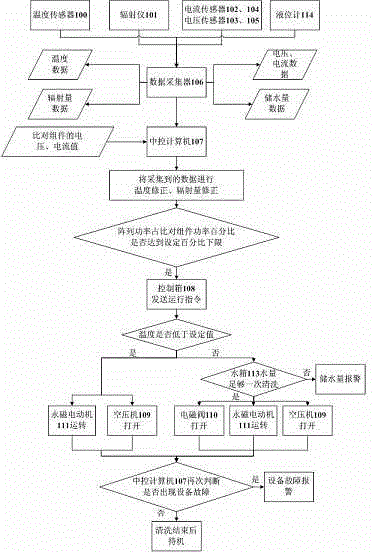

[0024] as attached figure 1 Schematic diagram of the structure of the fully automatic solar array air pressure water / steam dual-purpose cleaning system; figure 2 Operation flowchart of fully automatic solar array air pressure water / steam dual-purpose cleaning system; figure 1 , attached figure 2 As shown, the temperature sensor 100 and the radiometer 101 of the present invention are coplanar with the array to be cleaned, and the real-time temperature and radiation signals are collected and transmitted to the data collector 106. The current sensor 102 and the voltage sensor 103 are installed at the photovoltaic DC output terminal to collect real-time The current and voltage signals are transmitted to the data collector 106, and the current sensor 104 and the voltage sensor 105 are installed on the comparison component to collect real-time comparison current and voltage signals, which are transmitted to the data collector 106, and the comparison component is systematically pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com