Improved two-roller temper mill and using method

An improved, flattening machine technology, applied in the field of mechanical processing, can solve the problems of reduced industrial production efficiency, waste of time, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

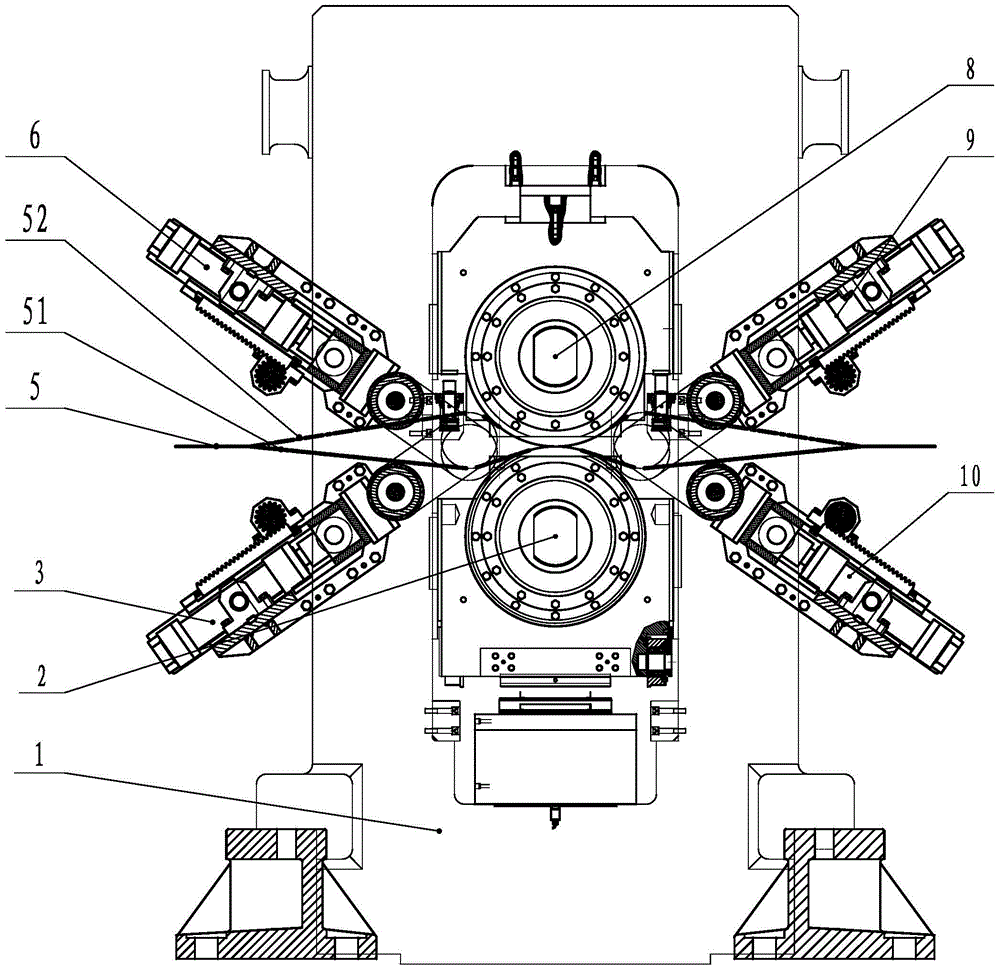

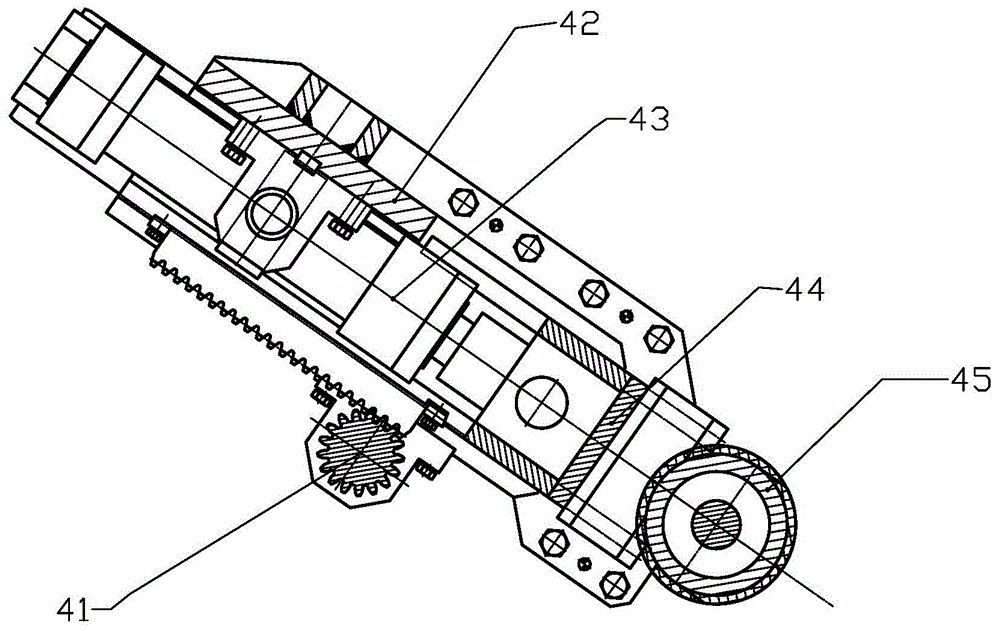

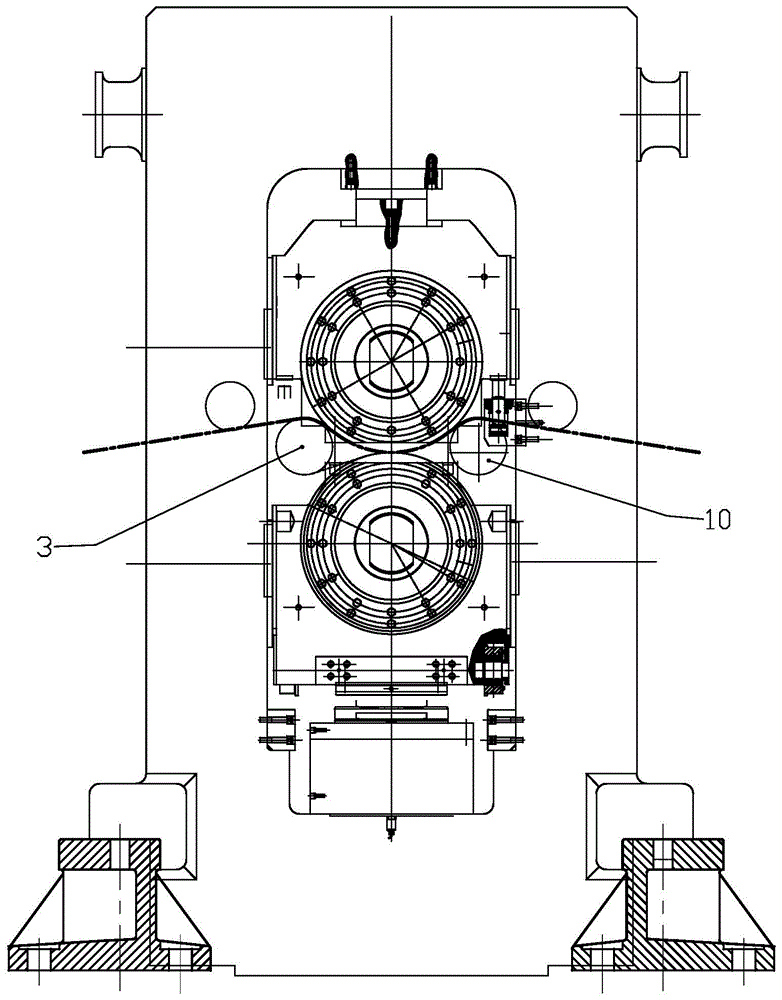

[0024] Such as Figure 1 to Figure 4 As shown, an improved two-roll skin pass machine, including the main body 1, the lower work roll 2, the lower left anti-wrinkle roll group 3, the left upper anti-wrinkle roll group 6, power components, the upper work roll 8, and the right upper anti-wrinkle roll group 9 and the lower right anti-wrinkle roll group 10. There are two sets of anti-wrinkle roll sets on this improved two-roller skin passer. The anti-wrinkle roll sets and the work rolls are used crosswise. 3 and the lower right anti-crease roll group 10, the first group of anti-crease roll group is used in conjunction with the upper work roll 8, such as image 3 As shown, an upper wrap angle is formed; and the second group is the upper left anti-crease roll group 6 and the upper right anti-crease roll group 9, and the second group of anti-crease roll groups is used in conjunction with the lower work roll 2, as Figure 4 As shown, a lower wrap angle is formed, which can effectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com