Refining method of high-purity trans-Alpha-methylcinnamaldehyde

A technology of methyl cinnamaldehyde and a refining method, which is applied in the field of fine chemical synthesis, can solve problems such as difficult separation and waste of resources, and achieve the effects of increasing yield, saving costs, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] In order to overcome the problems of high content of cis-α-methylcinnamaldehyde in the existing trans-α-methylcinnamaldehyde synthesis process, which is difficult to separate, waste and waste resources, this embodiment provides a high-purity trans-α-methylcinnamaldehyde The refining method of methyl cinnamaldehyde,

[0018] 1) Preparation of the crude product of α-methylcinnamaldehyde; the crude product of α-methylcinnamaldehyde obtained by condensation, neutralization and desolvation of benzaldehyde and n-propionaldehyde, wherein the crude product of α-methylcinnamaldehyde includes benzene Formaldehyde, benzyl alcohol, cis-alpha-methylcinnamaldehyde, trans-alpha-methylcinnamaldehyde, and 2-methyl-3-hydroxy-3-phenylpropanal.

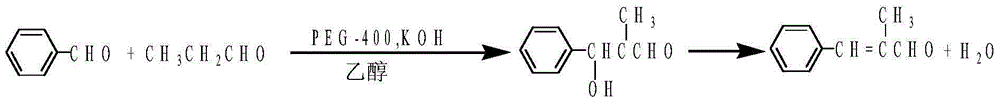

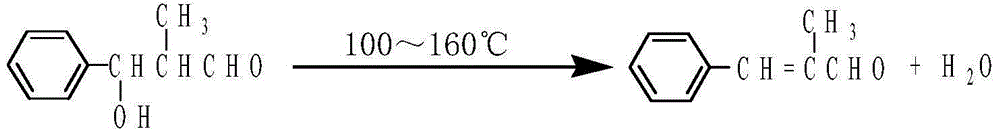

[0019] Wherein, the main reaction principle of benzaldehyde and n-propionaldehyde reaction is:

[0020]

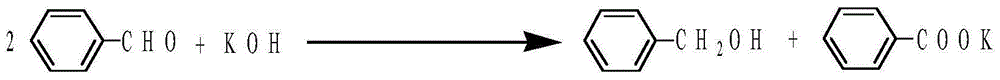

[0021] The side reactions in this reaction are:

[0022]

[0023] 2) primary rectification; the α-methylcinnamaldehyde crude product ...

Embodiment 2

[0034] On the basis of Example 1, this example specifically provides a method for refining high-purity trans-α-methylcinnamaldehyde:

[0035] First, 500 grams of the dehydrated crude product of α-methylcinnamaldehyde crude product obtained by condensation of benzaldehyde and n-propionaldehyde is rectified and purified under vacuum-0.099MPa, wherein the composition of the dehydrated crude product of α-methylcinnamaldehyde crude product is trans Formula α-methylcinnamaldehyde 75%, cis-α-methylcinnamaldehyde 2.5%, benzaldehyde 18%, benzyl alcohol 1.5%, obtain 95 grams of low boiling components, 50 grams of transition fractions, 330 grams of finished products, high boiling 20 grams; Among them, the transitional fraction is divided into cis-α-methylcinnamaldehyde 10.5%, trans-α-methylcinnamaldehyde 87%; the finished product components are cis-α-methylcinnamaldehyde 3.5%, trans-α - Methylcinnamaldehyde 96.2%.

[0036] Then, 300 grams of the finished product obtained above were rect...

Embodiment 3

[0039] This embodiment specifically provides a method for refining high-purity trans-α-methylcinnamaldehyde:

[0040] First, 500 grams of the dehydrated crude product of α-methylcinnamaldehyde crude product obtained by condensation of benzaldehyde and n-propionaldehyde is rectified and purified under vacuum-0.099MPa, wherein the composition of the dehydrated crude product of α-methylcinnamaldehyde crude product is trans Formula α-methylcinnamaldehyde 75%, cis-α-methylcinnamaldehyde 2.5%, benzaldehyde 18%, benzyl alcohol 1.5%, obtain 95 grams of low boiling components, 50 grams of transition fractions, 330 grams of finished products, high boiling 20 grams; Among them, the transitional fraction is divided into cis-α-methylcinnamaldehyde 10.5%, trans-α-methylcinnamaldehyde 87%; the finished product components are cis-α-methylcinnamaldehyde 3.5%, trans-α - Methylcinnamaldehyde 96.2%.

[0041] Then, 300 grams of the finished product obtained above were rectified and purified under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com