Polystyrene vinyl propionate and preparation method therefor and application thereof

A technology of polystyrene vinyl propionate and vinyl propionate, which is applied in construction and other fields, can solve the problems of large dosage, unsuitable for oil production, and few types of tracers, and achieve the effect of low dosage and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

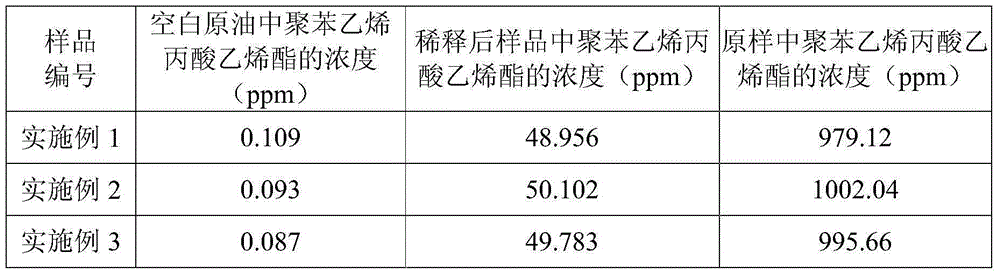

Examples

Embodiment 1

[0028] This embodiment provides a method for preparing polystyrene vinyl propionate, which includes the following steps:

[0029] a. Dissolve 0.4g of vinyl bis-stearic acid amide in 50g of hot water, and raise the temperature to 65°C for 30 minutes to obtain an aqueous solution of vinyl bis-stearic acid amide;

[0030] b. Slowly add 45g of vinyl propionate, 5g of styrene and 0.6g of benzoyl peroxide to the aqueous solution of vinyl bisstearamide at a speed of 5-10 drops / min. The addition is complete. After reacting for 10 hours, the temperature is lowered to room temperature and the material is discharged to obtain polystyrene vinyl propionate with a particle size of 0.425mm-0.850mm (20 mesh-40 mesh).

Embodiment 2

[0032] This embodiment provides a method for preparing polystyrene vinyl propionate, which includes the following steps:

[0033] a. Dissolve 0.5 g of vinyl bis stearamide in 55 g of hot water, and raise the temperature to 65°C for 30 minutes to obtain an aqueous solution of vinyl bis stearamide;

[0034] b. Then slowly drop a mixed solution of 40g vinyl propionate, 4.5g styrene and 0.5g benzoyl peroxide into the aqueous solution of vinyl bisstearamide at a speed of 5-10 drops / min, and add dropwise After completion of the reaction for 10 hours, the temperature is lowered to room temperature and the material is discharged to obtain polystyrene vinyl propionate with a particle size of 0.300mm-0.600mm (30 mesh-50 mesh).

Embodiment 3

[0036] This embodiment provides a method for preparing polystyrene vinyl propionate, which includes the following steps:

[0037] a. Dissolve 0.6g of vinyl bisstearic acid amide in 60g of hot water, and raise the temperature to 65°C for 30 minutes to obtain an aqueous solution of vinyl stearic acid amide;

[0038] b. Slowly add a mixed solution of 35g vinyl propionate, 4g styrene and 0.4g benzoyl peroxide to the aqueous solution of vinyl bisstearamide at a speed of 5-10 drops / min, and the addition is complete. After reacting for 10 hours, the temperature is lowered to room temperature and the material is discharged to obtain polystyrene vinyl propionate, the particle size of which is 0.212mm-0.300mm (50 mesh-70 mesh).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com